Material Handler with electric travel drive developed by SENNEBOGEN

At ligna 2019, in Hanover, SENNEBOGEN will showcase a new electric drive version of the diesel hydraulic Pick & Carry Material Handler SENNEBOGEN 735 that is so popular with the timber industry. The prototype is currently being field tested and will be ready to go into production by the end of 2019.

When it comes to mobile timber handling, many customers around the world depend on the reliable Pick & Carry material handler from SENNEBOGEN. These machines are mainly used in log yards to organize and sort, and to feed saw mills.

The 7 series machines have been designed to run continuously. Electric solutions, such as those typically used in stationary timber manipulation, have not been possible due to the long travelling distances involved. At ligna, SENNEBOGEN will present the first machine with a new drive concept.

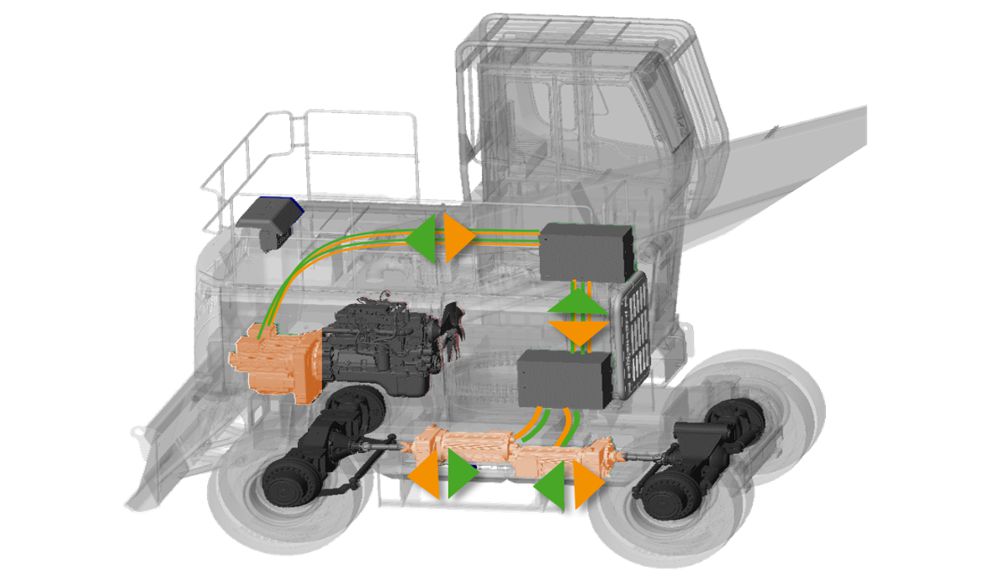

All the work process still operate hydraulically, driven by an efficient stage 5 diesel engine, whilst the undercarriage travel drive is electric.

Joint development Material Handler project with Bosch Rexroth

Bosch Rexroth and SENNEBOGEN, long-term partners in drive and application technology for material handlers, collaborated to develop this electric travel drive. The system solution is based on Bosch Rexroth components, is being jointly developed into a marketable product, and will be launched by SENNEBOGEN under the name ‘Green Efficiency Drive’.

The Pick & Carry material handler 735 E will be the first machine to contain the series production technology for electric travel.

Design: up to 30 % more efficient thanks to the electric travel drive

The Pick & Carry machine can already switch continuously between acceleration, braking and driving under load and this provided options for improving the use of the available energy.

The new drive concept consists of two electric drive engines in the undercarriage which are supplied with power by a generator operated by a diesel engine. In addition to the increased efficiency and lower consumption of this design, the development team have also managed to achieve a reduction in noise levels, and dynamic drive and braking in the pilot production.

Initial applications saw efficiency increases of up to 30 % compared to the previously used diesel-hydraulic drive. The machine has already been very convincing in field tests with one customer. The machine was used for several days in the log yard of a Bavarian saw mill.

Experience the SENNEBOGEN 735 E with Green Efficiency Drive at ligna

As the first 7 series model, the SENNEBOGEN 735 E with the prototype Green Efficiency Drive will be on display at ligna. Additional technical details will also be available there. The new drive concept is currently undergoing intensive testing and the first models will be ready to go into production by the end of 2019.