Tenneco develops engine wear-resistant materials to end reliance on cobalt

An innovative new material from Tenneco powertrain business group delivers wear-resistant performance with greatly reduced cobalt content, helping engine manufacturers mitigate the limited availability and price volatility of cobalt.

Demanding high temperature applications that typically rely on cobalt to provide wear resistance in high temperature ranges, such as heavy-duty turbocharger wastegate bushings, EGR valves, and high performance engine valve seats will benefit from the new material. Using an alternative sintered steel formulation, trials have shown that the cobalt content in Tenneco’s sintered materials can be reduced significantly without compromising wear resistance.

“Potential material shortages and controversy around cobalt mining, coupled with extreme price volatility, mean we must reduce our dependence on cobalt,” said Gian Maria Olivetti, Vice President Global Engineering, Tenneco Powertrain. “While it remains the most effective material to combat wear in dry running valve seat applications and other components subjected to big temperature ranges, we have used our extensive experience in powder metallurgy to develop a low-cobalt sintered formulation alternative that delivers similar wear properties to the best current materials.”

The application temperatures for bushings in EGR valves, turbocharger wastegate systems or exhaust-gas valves can range from below 0°C up to 1000°C, and it is this wide variation that makes the tribology challenging, as Jens Wellmann, Tenneco Powertrain product manager for turbocharger components, explains. “Especially in the lower temperature range up to ~400°C high-cobalt materials can outperform the typical non-cobalt materials. The first question we had to answer was: ‘What is the explanation for high-cobalt material’s low wear rates?’ And the second question was: ‘How much cobalt is effectively needed to produce that effect?’.”

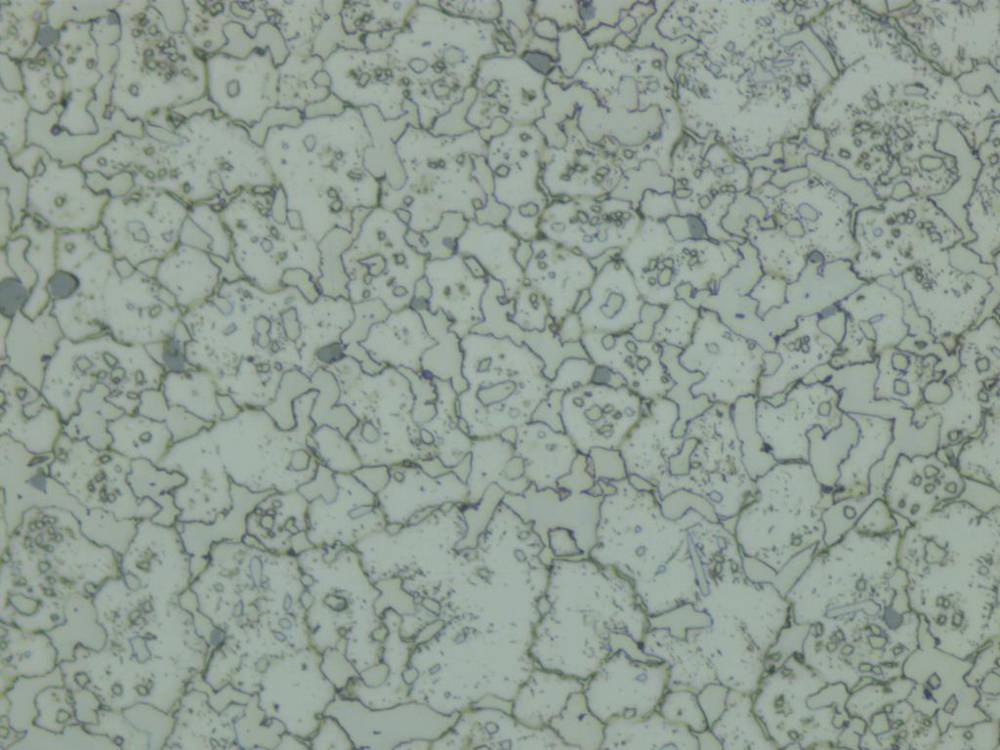

Tenneco’s research started from two well-proven existing sintered products; FM-8100, an iron-based cobalt-free sintered material, and FM-T95A, a cobalt-based (54% Co by weight) sintered material comparable to the cast materials used for tribological applications. Between these two extremes, a total of five materials with varied cobalt content were evaluated for wear performance across a range of temperatures. Investigation of the worn specimen showed that the cobalt-containing Tenneco sintered materials formed a wear-reducing tribolayer at lower temperatures than the cobalt-free one. This early forming of a stable tribolayer gave the answer to the first question.

Comparing the samples, the same effect was examined on 17 to 35 percent Co materials, which provided the answer to question 2. Based on these results, a new material was developed, designated FM-T88A, a sintered steel with 17 percent Co, which met production and quality requirements, including the manufacturability and mixing of the metal powder, the sintering process, machinability and quality assurance.

To verify the results of the initial tests, collaborative trials were conducted with a major global vehicle manufacturer comparing the wear resistance of FM-T88A against series production materials. This was undertaken in a test rig which simulated the installation and loading of a turbocharger wastegate bushing running at temperatures up to 800°C.

“The results showed that at 200oC, FM-T88A displays a significantly reduced depth of wear compared to a cobalt-free material and is at a comparable level of wear resistance to the high-cobalt material,” says Wellmann. “At all other temperatures the new material’s performance closely mirrored the high-cobalt materials.”

“With 50 percent of the cobalt mined globally now used in batteries for electrified vehicle powertrains, demand for the material is growing year on year,” said Olivetti. “By minimizing the levels of cobalt used in our wear-resistant high temperature sintered materials, we can help our customers mitigate the limited availability and price volatility of cobalt while still delivering robust products.”