Designing the world’s first electric flying racing car

At Goodwood Speed Week, Airspeeder unveiled to the world the Mk3 racing prototype. This remotely-piloted craft showed the form of the world’s first full-scale and functional electric flying racing car.

Today, the production version of this revolutionary vehicle is being created at the sport’s technical headquarters in Adelaide, South Australia. Airspeeder is proud to confirm the technical specifications of these craft before they participate in remotely piloted races throughout the second half of 2021.

Matthew Pearson, Founder, Airspeeder and Alauda Aeronautics , said: “Some of the very first Mercedes, Bentleys and Renaults were racing cars. The pioneers of these marques knew that in order to advance a mobility revolution, they must build their machines for racing. At Airspeeder, we proudly echo that philosophy. To accelerate the arrival of advanced air mobility technology we must leverage sporting competition. The Airspeeder Mk3 is the result of years of engineering, testing and development with the pure purpose of creating the ultimate performance electric flying car.”

Airspeeder’s mission is to accelerate a zero-emissions, advanced air-mobility revolution through intense sporting competition. This approach reflects the work of pioneers such as C.S Rolls, W.O Bentley and Karl Benz who built acceptance for what was then a revolutionary new technology, and accelerated their development, by going racing.

Alauda Aeronautics, sister-company to Airspeeder, is currently building ten of these vehicles for races set to take place on three continents in the coming months.

Design

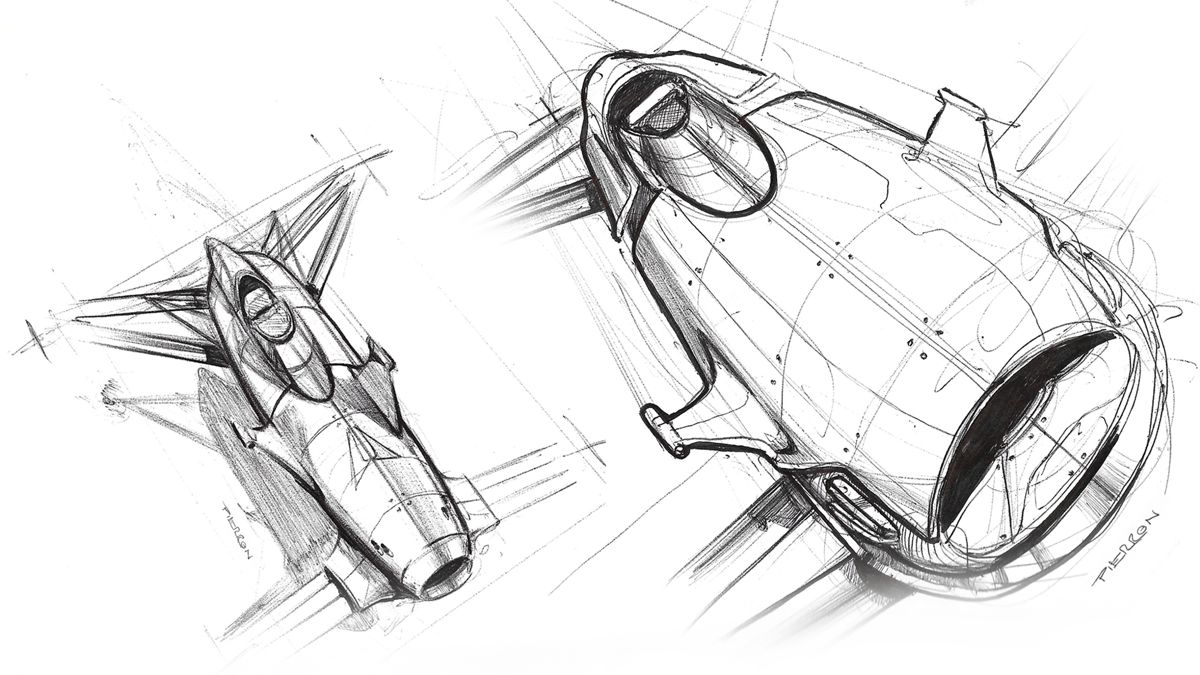

In conceiving the form of the world’s first electric flying racing car, Head of Design, and Royal Academy of Art Graduate, Felix Pierron, was unusually unburdened by the limitations associated with performance vehicle design. When creating an entirely new vehicle for a future sport, there are no rules, precedents or preconceptions. In that sense Pierron has been free to create an entirely new aesthetic expression of the future of advanced air mobility.

Felix Pierron, Head of Design, Airspeeder and Alauda , said: “My first principle is that our Speeders are racing craft first. In ideating a design approach I explored the classic forms of racing cars from the 1950s and 1960s. This was a time when the requirement for beauty was equal to technological and aerodynamic necessity. As a designer, there is no better place to start. I am excited to see something that started as a vision on paper taken to the air. My dreams are no longer my own, they are now an incredible reality to inspire the world .”

His vision represents the marriage of an F1 car, a fighter jet and helicopter. In functional terms, when crewed racing begins in 2022 and beyond, the pilot will sit in the cockpit in the same manner a driver is placed in a modern Formula 1 car. Fastidious attention to the ergonomics of the cockpit have been paid to ensure that nothing distracts the pilot from the purity of their purpose; to fly their machine at the absolute limit.

The upcoming uncrewed series will do much to teach Felix and the wider engineering team about the dynamics of these craft and will serve as the perfect proving ground for what promises to be the most progressive and entertaining form of motorsport in the world.

Beyond the inspiration drawn from those classic racing forms of the 1960s. Pierron referenced the Seaplanes that flew so gracefully and purposefully in the waters adjacent to Monaco in the Schneider Trophy, a major agent of progress at the dawn of the aviation age. The iconic Spitfire design lineage can be traced back to these races and are referenced today in Pierron’s aesthetic treatment for the elegantly tapered front-third of the Airspeeder Mk3.

Pierron takes from this an understanding that the purpose of racing new forms of mobility goes beyond just technical advancement. It is a mission to win hearts and minds and for that form must be as important as function.

Felix Pierron, Head of Design, Airspeeder and Alauda , said: “This is pure innovation. We are not constrained by four wheels or a square frame. We are leading an entirely new aesthetic; racing flying vehicles. It will take at least a century to define an era as we are today. I am very proud to fulfil my responsibility of making machines that are as beautiful as they are purposeful.”

Performance

The eVTOL (electric vertical take-off and landing) sector, which is predicted by Morgan Stanley to be worth $1.5 trillion by 2040, is already transforming logistics and even providing medical supplies to remote regions. However, the passenger transport side of the industry has been very much focused on what is termed ‘electric flying taxis’. These promise to transform urban environments and free them from congestion with safe and sustainable transport.

To realise the potential of this technology, a space and place must be created to rapidly accelerate the key elements that will underpin global mass-adoption of advanced air mobility for passenger applications. Racing, as it was for the motorcar and aeroplane, is the answer.

Airspeeder will pioneer a suite of technologies that will refine and demonstrate safety requirements, build acceptance for eVTOL and, as a form of future transport, answer key questions around battery technology, noise and regulation.

The Mk3 remotely-piloted electric flying racing car is at its heart a performance machine. At maximum power it delivers 320kW, equalling an Audi SQ7 performance SUV. The Audi weighs 2,500kg while an Airspeeder racing craft (without pilot) weighs just 130kg. It can lift a weight of more than 80kg, proving the viability of the powertrain for piloted races. Acceleration from 0-62mph takes 2.8 seconds and the Speeder can climb to 500 meters.

A Speeder can turn with extraordinary speed when compared to a traditional fixed wing aircraft or helicopter. The Mk3 vehicle has a thrust-to-weight ratio of 3.5, which exceeds that of an F-15E Strike Eagle (thrust-to-weight ratio of 1.2), one of the most advanced fighter aircraft in the world. The thrust-to-weight ratio, along with other powertrain characteristics, has been verified as part of the exhaustive testing and development programme that preceded the start of full production. Indeed, the rapid hairpin turning potential achieved through an octocopter format has been compared to that of a Formula 1 car, generating up to 5Gs, with the added capability to manoeuvre vertically.

The Airspeeder engineering and technical team is drawn from some of the leading names in performance and racing vehicle engineering including Mclaren, Tom Walkinshaw Racing and Brabham. On the aviation side of the garage, members of the team have led major projects in both civil and military aviation, including Project Lead Brett Hill’s experience as a flight dynamics specialist on the Boeing 747-8 programme.

Together they have developed an advanced carbon fibre structure, carrying strength and weight-saving benefits. Indeed, there is an obsession at Alauda with shedding grams to gain critical seconds in performance. An Airspeeder vehicle consists of a chassis and carbon fibre moulded ‘tub’-style skin. This ensures overall strength to maintain the structural integrity of the vehicle under extreme racing conditions and manoeuvres.

Batteries have been re-designed versus the previous iteration of the Airspeeder to have 90% more capacity with only a 50% increase in weight. The specification of these cells also delivers an exciting strategic layer. Power delivery profiles can be changed by ground-crews to respond to the different requirements of the electronically governed sky-tracks that Airspeeder pilots will follow. For example, a lay-out that demands rapid maneuvers through sharp turns and ascents will require a different power delivery curve from those that demand outright straight-line speed. Ground crews will have to make instant decisions around sacrificing raw power for outright range.

Every Airspeeder includes rapid pit stops. To facilitate this, Alauda’s engineers have developed an innovative ‘slide and lock’ system for the rapid removal and replacement of batteries when on the ground. This technology debuts on the Mk3. Intense internal competition between inhouse pit-crews has driven the pitstop time down to just 14 seconds, which is entirely compatible with any form of ground-based legacy motorsport. This is expected to continue to fall. For context, a Formula 1 pitstop used to take more than a minute.

Safety at the limit

Airspeeder employs a systems-based approach to safety. This is a recognised methodology from military, civilian and performance aviation. This means that no single operational failure can lead to loss of the primary function of the vehicle, which is controlled flight.

In the early stages of the Mk3’s development simulation, bench testing and integration testing techniques were employed to fully map out these systems. Ahead of live testing, this gave engineers confidence that in the event of a systems failure, vehicles will remain in the air but at reduced performance to ensure the pilot, whether operating remotely in the case of the Mk3, or in the cockpit in future iterations, will be able to safely return to the ground.

During flights, all systems are monitored on the ground through state-of-the-art telemetry. This means that groundcrew are immediately aware of issues and can take appropriate action to bring the craft to ground under control.

Prioritising safety is also inherent to the architecture of the vehicle. The octocopter layout ensures stability in the event of rotor failure or breakage, while the carbon fibre structure of the Speeder has been engineered for overall structural integrity.

The Mk3, which will be operated by an expert remote operator from the ground, features a suite of technologies and engineering elements never before seen on an eVTOL craft. These innovations will be validated in this key uncrewed proving phase and include LiDAR and Radar collision avoidance systems that create a ‘virtual forcefield’ around the craft to ensure close but ultimately safe racing.

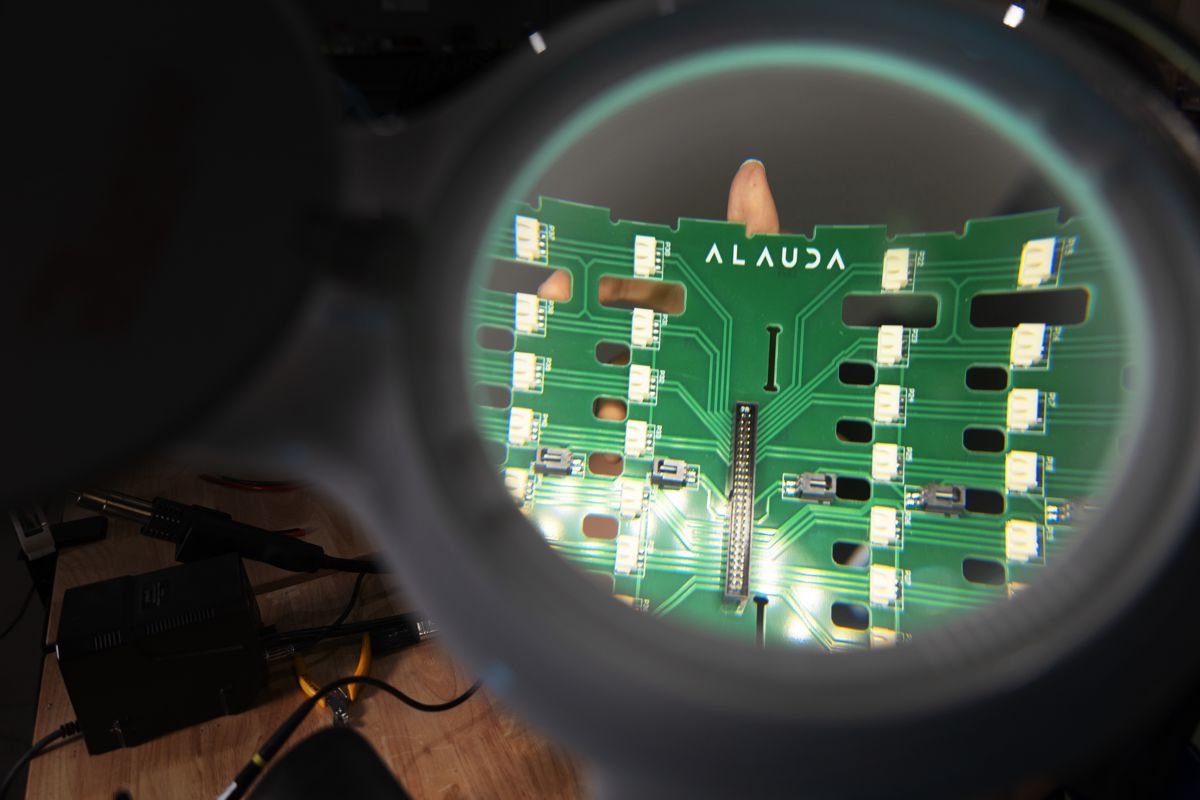

Driven by data

Terabytes of data from sensors within every area of the Speeder’s architecture is drawn over any testing or racing cycle. This means on-the-ground pit crews are able to constantly analyse and react to even the smallest variance in performance. From a racing perspective this dictates strategy and pilot approach, and in overall technical terms allows engineers to understand details like aerodynamic performance and even adjust propeller settings in accordance with Speeder behaviour in a multitude of conditions.

Airspeeder works with global cyber protection leader Acronis and their delivery partner Teknov8 to secure this data.