Teledyne Thermal Technology helps Electrical Inspections for Oil and Gas Industry

When electrical connections and components break down unexpectedly, the result may be unplanned downtime, costly repairs, and production loss.

There’s also an increased risk of fire due to electrical short-circuits or cable burning. That’s why it’s important to perform routine checks to ensure that the electrical distribution system is in proper working order, including inspection of busbars, circuit breakers, fuses, and switchboards.

Electrical distribution boards are typically housed inside cabinet enclosures, making them difficult to inspect for impending failures.

The Solution

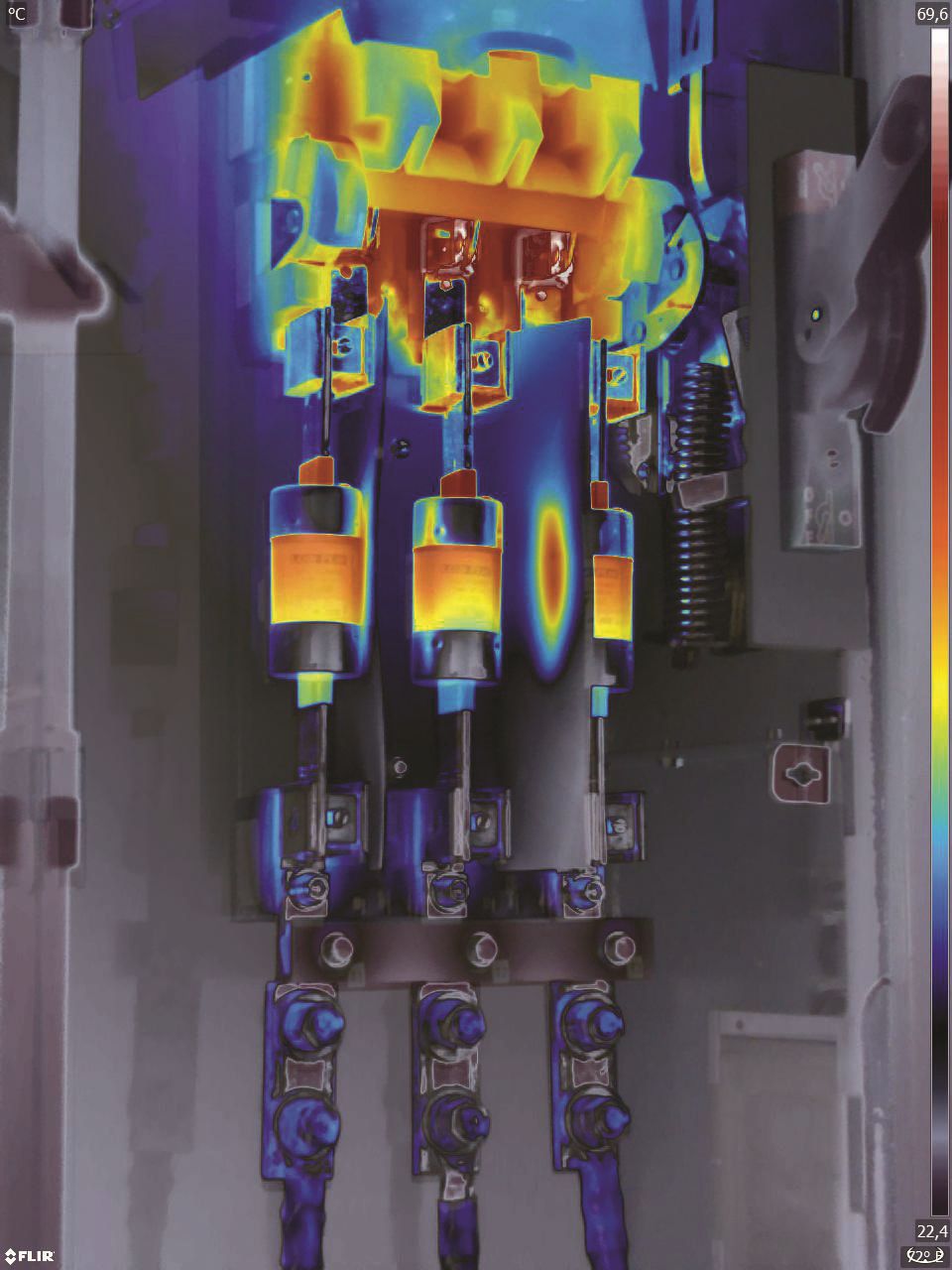

Electrical connections and components typically show signs of overheating before they fail.

Thermal imaging technology can provide key information that the eyes alone cannot detect. A thermal camera, such as the FLIR E95, can show maintenance professionals hot spots on components and connections, helping them recognize stressed elements of an electrical installation before failure and break down.

This gives them the opportunity to solve electrical issues as part of planned maintenance before it causes a serious and costly problem.

Maintenance professionals can also use thermal imaging in combination with other instruments including clamp meters, digital multi-meters, and IR Windows to ensure the distribution system is operating optimally.

The Result

Through regular thermal inspections, maintenance professionals can quickly detect and locate temperature issues (hot spots) on electrical components and equipment.

Loose connections, bad contact, fuse issues, unbalanced loads, and stressed earth leakage can be discovered using a thermal imager.

Improve safety by reducing risk of electrical fire; avoid unexpected breakdowns; reduce risk of unplanned electrical outages; and organize planned repairs and preventive maintenance.