Cracking the secrets to Earthquake Safety

A new experimental facility, designed to replicate realistic earthquakes in the laboratory, paired with the world’s fastest supercomputers, will help lead to resilient buildings and infrastructure across the U.S.

To make sure our buildings and infrastructure are earthquake-safe, we must understand how seismic activity affects different structures. Miniature models and historical observations are helpful, but they only scratch the surface of understanding and quantifying a geological event as powerful and far-reaching as a major earthquake.

Two major research efforts funded by the Department of Energy (DOE) seek to fill in the gaps and provide resources for researchers and engineers to study earthquakes across scales, from the initiation of seismic waves at the fault rupture site deep underground, to the interactions between shaking soil and individual structures at the surface.

The first endeavour is an experimental facility for real-world studies on how the soil around a structure influences its performance during an earthquake. The ground beneath us may seem solid, but vibrations can quickly make it unstable. This is because soils are composed of complex layers of rock and mineral particles in varying sizes with varying levels of moisture that each respond differently to seismic activity.

During an earthquake, the movements of buildings are dictated by site-specific interactions between these soil layers and the direction and strength of the vibrations. Now nearly complete after more than five years of design and construction, the Large-Scale Laminar Soil Box System will be the largest facility in the U.S. for studying these interactions, and comparable in size to the largest one in the world.

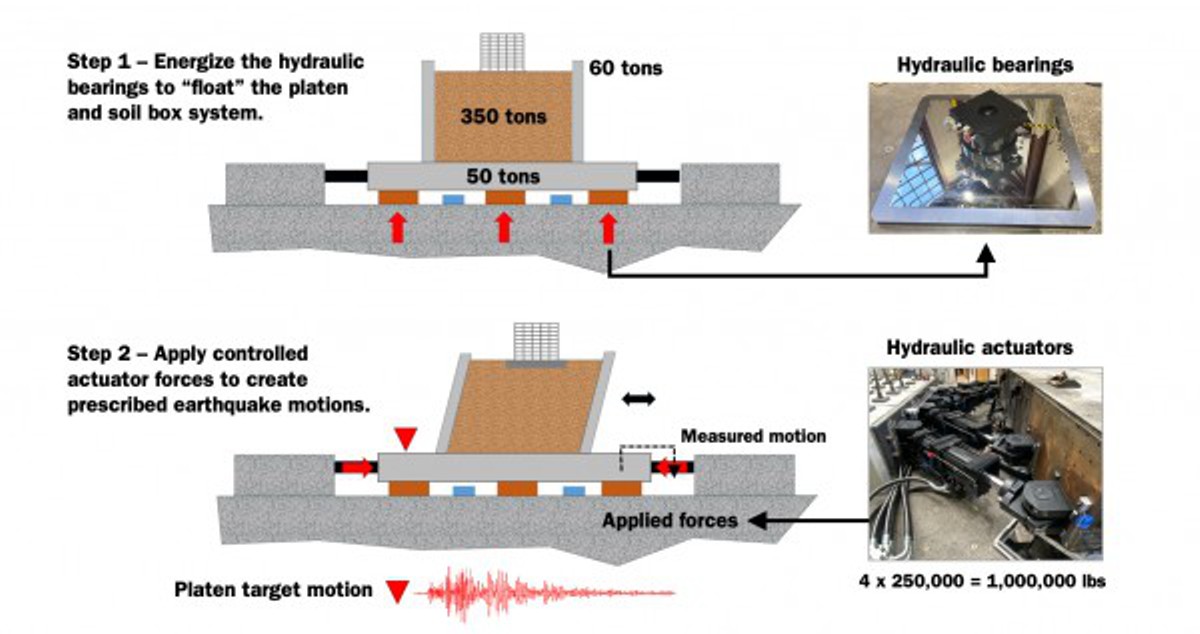

The facility is a collaboration between the University of Nevada, Reno (University) and Lawrence Berkeley National Laboratory (Berkeley Lab). It consists of a 350-ton capacity soil container mounted on a hydraulic base that can replicate shaking with up to one-and-a-quarter million pounds of force. The facility opened with a celebratory demonstration event at the University on September 15.

Studies conducted with the Soil Box System will provide data for the other effort, EQSIM: an ongoing collaboration between scientists at Berkeley Lab, Lawrence Livermore National Laboratory, and the University to develop realistic, highly detailed earthquake simulations using DOE’s supercomputers.

“These projects are synergistic. The Soil Box System is helping us understand and refine how to model the complex interaction between the soil and a structure. Our objective is to make realistic models of specific interactions – for example, what happens to a 20-story building very near California’s Hayward fault during a large-magnitude earthquake? – and add them to our existing large-scale simulations,” said David McCallen, a senior scientist in Berkeley Lab’s Earth and Environmental Sciences Area and EQSIM leader. “We want to model all the way from the fault rupture through the ground to the structure to see how buildings and other infrastructure in an entire region will respond.”

A new avenue for real-world testing

The soil box project was launched in 2015 out of a need to safeguard Department of Energy buildings that hold sensitive scientific instruments against any potential earthquake scenario. “It was driven by how little we knew about the way soil surrounding the foundation of a building affects its performance during an earthquake,” said Soil Box System principal investigator Ian Buckle, a Foundation professor in the University’s Department of Civil & Environmental Engineering. “For buildings on shallow foundations, there’s probably not much effect. But for those with deeper foundations, such as nuclear facilities and long-span bridges, the answer is perhaps a great deal.”

The design team, led by Buckle and fellow University professors Sherif Elfass and Patrick Laplace, devised and fabricated the system to have the largest possible soil container, so that representative structures could be placed on top. A management committee was formed to help guide the team through this challenging project. In addition to those named above, the committee also comprised University Professors Ramin Motamed and Raj Siddharthan.

The 15-foot-high, 21.5-foot-wide box sits on a 24-foot square shaking platform controlled by 16 hydraulic actuators. The soil container has 19 layers, called laminates, that are each supported on elastomeric (rubber-like) bearings so that soil layers can move relative to each other like soil does during actual earthquakes. The system can displace and accelerate 350 tons of soil – and the structure on top – in two horizontal directions simultaneously with the same force as a strong earthquake, and is so powerful that the designers had to build in safeguards to prevent it from destroying itself during experiments. The hydraulics are controlled by custom software and the box is equipped with a suite of sensors so that the scientists can gather detailed datasets to feed into their computer simulations.

“A soil box and shake table of this size and complexity are not something you order from an online catalogue. There are very few organizations or companies with the knowledge and expertise to do this, so we decided to do it ourselves with our own expertise and resources,” said Buckle. “This design not only allows us to work with large-scale structural models that can be placed on top of the soil, but also the large-scale allows more realistic soil properties to be modelled.”

Once operational, the facility will become a resource for DOE researchers focused on seismic safety as well as scientists across academia and industry. James McConnell, Associate Principal Deputy Administrator in DOE’s National Nuclear Security Administration, said: “It’s important for DOE and NNSA to invest in this work to ensure that the large, complicated, one-of-a-kind facilities we build are designed to protect the country’s research, defence, and energy-generation needs, but the findings have an added benefit of helping engineers and architects in industry and the private sector build a wide range of earthquake-resilient structures.”

Leveraging a new generation of supercomputers

Current models of earthquake properties rely on approximations and simplifications due, in part, to the lack of real-world data on the fundamental physics involved, but also because very few computers on the planet are actually capable of running earthquake simulations at the fidelity required to perform infrastructure damage assessments. That’s why McCallen and his EQSIM colleagues have been using the Summit supercomputer at Oak Ridge National Laboratory and the Perlmutter supercomputer at Berkeley Lab to develop very large, detailed models – like their simulations of the San Francisco Bay Area for M7 Hayward fault earthquakes – which has 391 billion model grid points.

They will also soon start working on an even more capable platform – the newly launched Frontier supercomputer, also at Oak Ridge. Frontier is the first computer system to break the exascale barrier, meaning that it is capable of calculating at least a billion billion (also known as a quintillion, or 1018) operations per second, and is currently ranked as the world’s most powerful supercomputer.

Using these exceptionally fast machines, the team will be able to add new insight and information on soil response and soil-structure interaction gained from the Soil Box experiments into their existing large-scale models. The longstanding goal of rupture-to-structure modelling is now becoming a computational reality. Their simulations will then be made available to the public through the Pacific Earthquake Engineering Research (PEER) Center’s open-access database of simulations. PEER is a multi-institution research centre focused on performance-based earthquake engineering, led by UC Berkeley.

“Part of our plan is to be able to enhance the available data sets of measured earthquake motions with our very dense, very detailed simulated motions and make these motions available to the broad earthquake science and engineering communities,” explained McCallen, who is also the director the University of Nevada, Reno’s Center for Civil Earthquake Engineering Research. “And so we will collaborate with PEER, which has a long history and necessary infrastructure for providing open access to recorded earthquake ground motions so that they can share them freely with the entire community to the benefit of all. Because not everybody has a Frontier sitting on their desk.”

The Soil Box project has been supported by DOE’s Office of Environment, Health, Safety and Security’s Nuclear Safety Research and Development Program, and by DOE’s National Nuclear Security Administration. The EQSIM is an application development project within DOE’s Exascale Computing Project.