Computer Vision breakthrough brings Anomaly Detection to any Edge Device

Edge Impulse, the leading platform for building, refining and deploying machine learning models to edge devices, has unveiled a novel technology for unlocking visual anomaly detection on any edge device, from NVIDIA GPUs to Arm MCUs, through the first model architecture of its kind: FOMO-AD (Faster Objects, More Objects – Anomaly Detection).

The demand for edge-capable AI software has increased as a path to innovating factories and production lines, with on-device computing allowing faster access to critical data insights, low latency, and more robust security and privacy compliance.

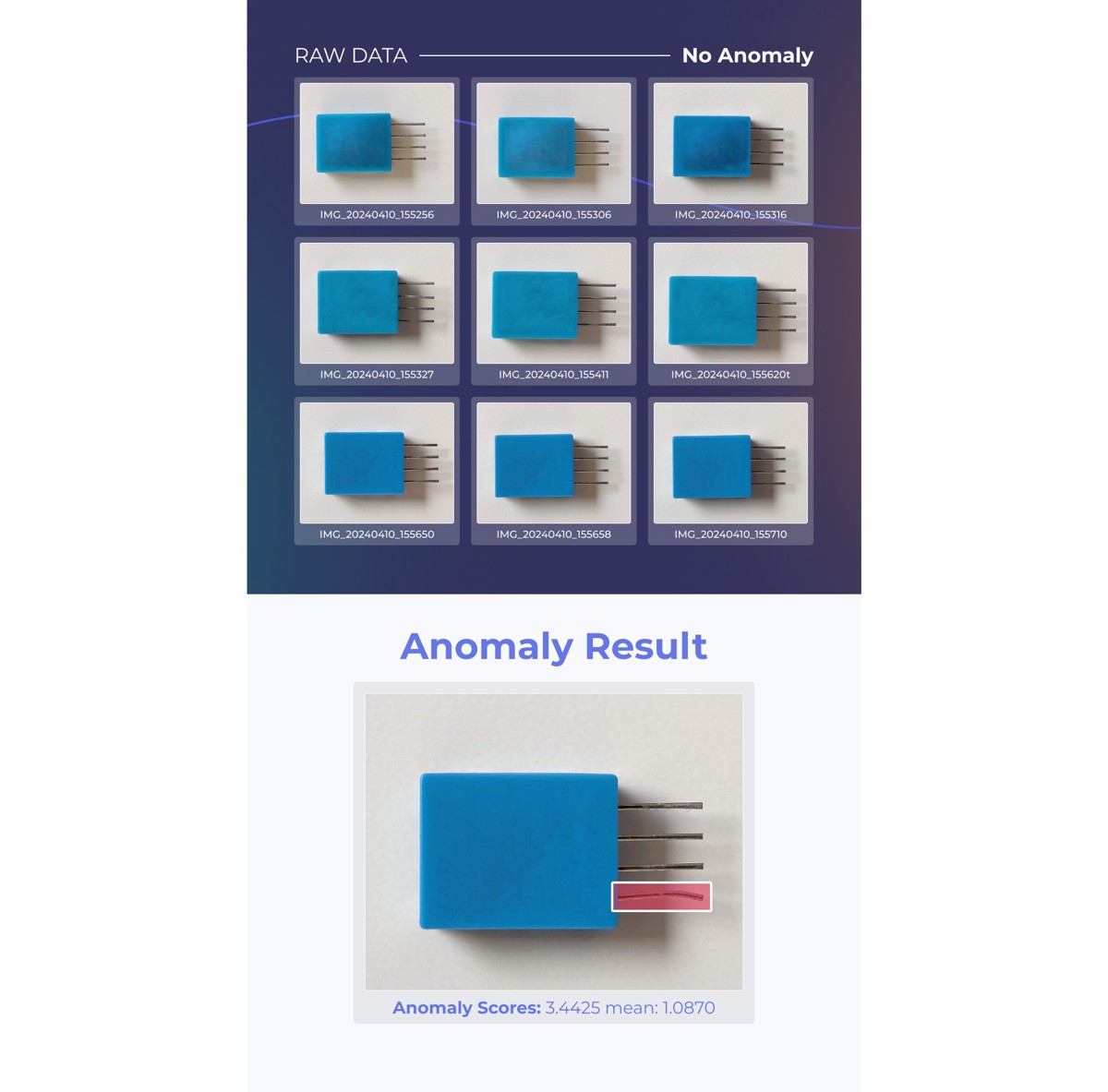

Visual anomaly detection in particular is an important use case for industrial AI, but is not widely used as it requires creating a library of known anomalous samples to train the model to spot deviations in industrial environments. Companies cannot collect real-world samples for every anomaly, especially for unanticipated defects, limiting detection capabilities.

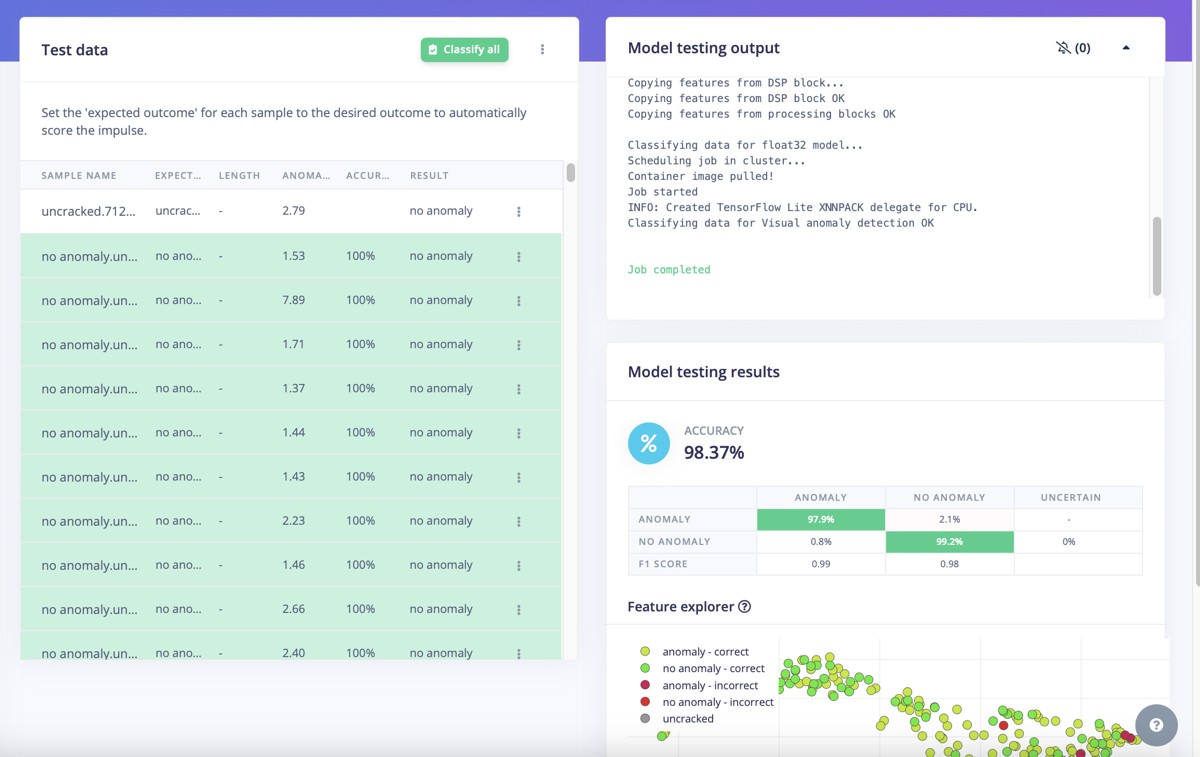

Edge Impulse’s FOMO-AD architecture, two years in development, offers the first widely accessible platform for visual anomaly detection on any edge device, from GPUs to MCUs. It is also the first scalable system capable of training models on an optimal state to detect and catalogue anything outside that baseline as an anomaly in video and image data. This dramatically increases the productivity of visual inspection systems that will no longer have to be manually trained on anomalous samples before they can start generating real-time insights on-device.

“Virtually every industrial customer that wants to deploy computer vision really needs to know when something out of the ordinary happens,” said Jan Jongboom, co-founder and CTO at Edge Impulse. “Traditionally that’s been challenging with machine learning, as classification algorithms need examples of every potential fault state. FOMO-AD uniquely allows customers to build machine learning models by only providing ‘normal’ data.”

Most industrial camera systems capable of computer vision are powered by GPUs and CPUs, with a high install cost that requires wiring and a power-hungry connection to mains electricity. Recent advancements from top-of-the-line silicon manufacturers, and novel edge model architectures from companies like Edge Impulse, enable computer vision AI models to operate in either high- or low-power systems, giving businesses more choice. The benefits of low-power systems include the possibility of building battery-powered visual inspection systems, and lower production costs from using cost-effective hardware that can reduce the overall product form factor.

In recent months, Edge Impulse has been testing FOMO-AD with customers, achieving proven results in industrial environments when proactively detecting irregularities in multiple production scenarios. Use of FOMO-AD has led to marked improvements in machine performance and production line efficiencies for customers.

There are many manufacturing use cases for visual anomaly detection, including:

- Industrial: Production line inspection, quality control monitoring, defect detection

- Silicon: IC inspection, PCB defect detection, soldering inspection

- Automotive: Part assembly quality control, crack detection, leak detection, EV battery inspection, painting and surface defect detection

- Medical: Medical device inspection, pill inspection, vial contamination inspection, seal inspection

Edge Impulse’s FOMO-AD architecture is available to enterprise plan users today and compatible with all edge devices.