Unlocking EVTOL Potential with Advanced Battery Behaviour Modelling

By 2030, the market for electric vertical take-off and landing batteries is projected to soar to $50 billion, highlighting the tremendous growth potential in this sector.

Currently, we’re witnessing the development of first-generation eVTOL batteries. However, the industry is poised for significant advancements, with future batteries expected to achieve energy densities of at least 300 Wh/kg at the pack level, specifically tailored for eVTOL applications. This progression promises to revolutionise urban air mobility and transform the aviation landscape

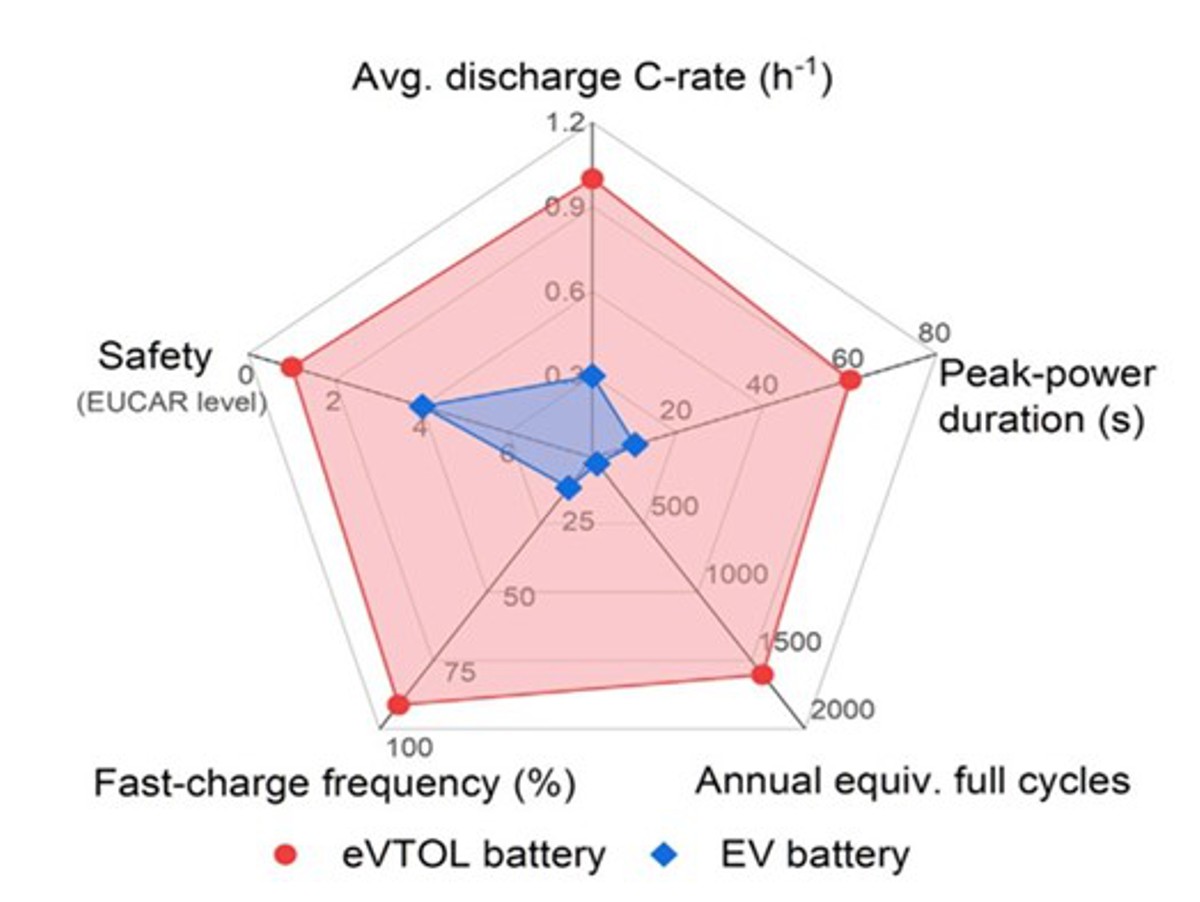

A key challenge is justifying the business case for mass-market appeal of these modes of transportation. This is because there is an intricate trade-off between commercial demands and technical aspects, such as safety, range, turnaround times, and battery life. The below figure shows the typical differences between an EV battery and an EVTOL battery.

Without comprehensive modeling and simulation, it’s challenging to precisely map product-level requirements and understand the intricate trade-offs between various technical factors. This knowledge gap often leads to conservative designs, resulting in oversized battery packs that impose unnecessary weight penalties on eVTOL aircraft.

However, the use of data and accurate simulations can help solve this because it eliminates the need to create expensive prototypes to test every new cell supplier or pack configuration.

Digital tools unlock pathways to accelerate battery development by reducing expensive design iterations. Modelling the intricate interplay between cell chemistry, architecture, and operating conditions guides product-level decisions that physical prototyping alone cannot fully optimise. To bridge the gap between cell-level factors and system-level performance effects, advanced computational models provide the fastest route forward.

Virtual modelling, for example can help ascertain the effect of pack design on thermal performance of cells connected in parallel, which in turn are coupled with current distribution through the cells. To investigate this, at About:Energy we would do this by using a combination of our electrical model, paired with our 2D thermal model.

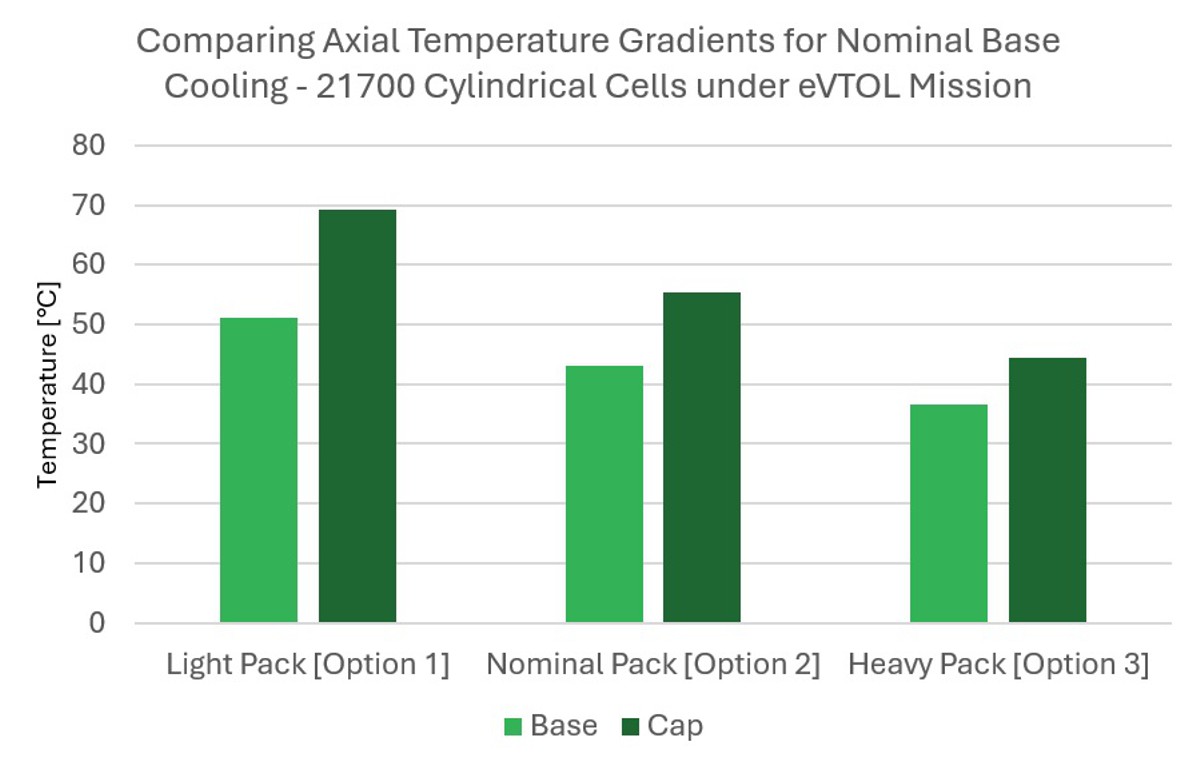

A base-cooled thermal management system in an eVTOL battery pack would then be simulated using high-power 21700 lithium-ion cells. As the number of cells is increased, the current requirement per cell decreases, and the temperature rise per cell decreases. However, the heavier the pack, the inherent power and energy requirements increase as the payload increases. Despite this, it is seen that the axial gradients within the cell decrease as the pack becomes heavier; potentially improving battery safety and lifetime.

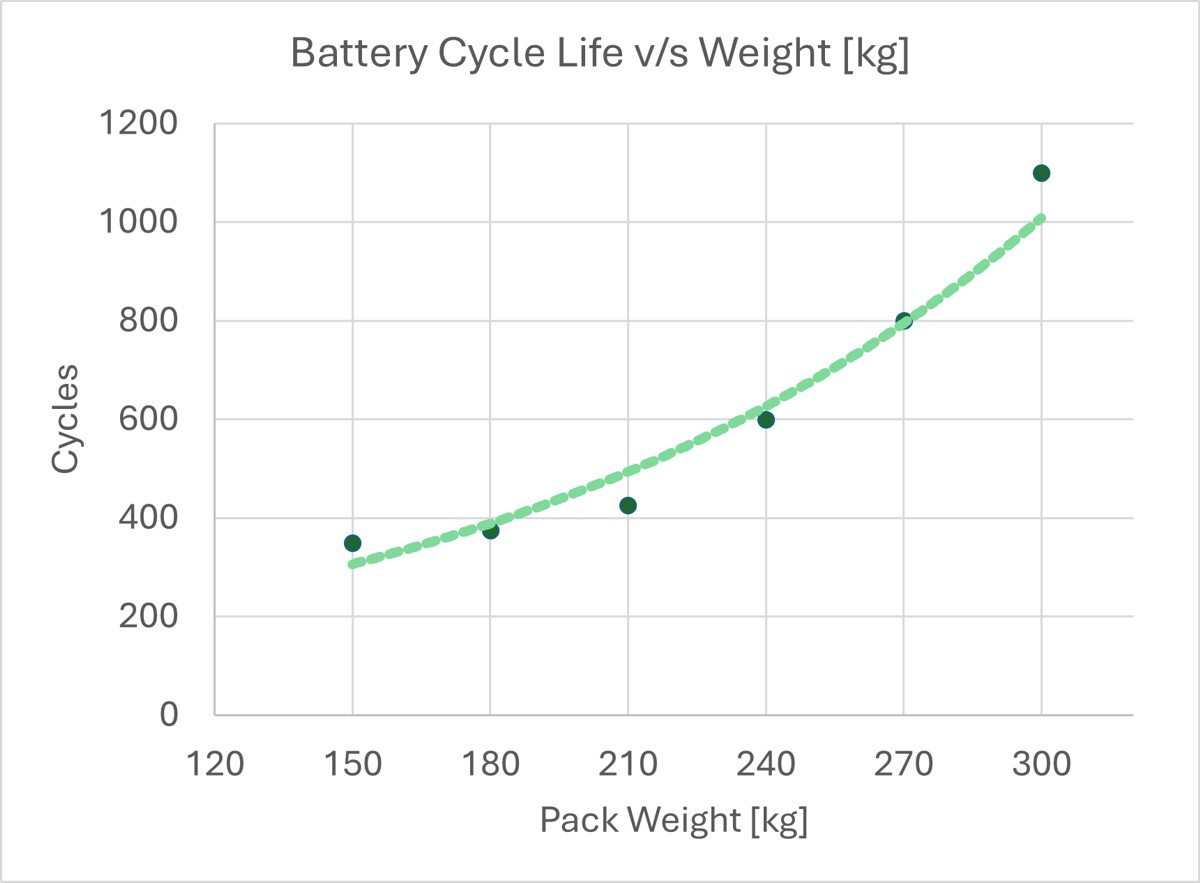

Using cell-level degradation data and electrical models, we have shown how eVTOL battery pack weight affects cycle life for running typical eVTOL missions.

For example, if one customer is asking to design a battery pack that runs for 1,000 cycles within a year, but with a 250 kg weight budget, this won’t be technically feasible and will necessitate aftermarket replacements, as a 250 kg pack would need to be changed every 6-8 months, meaning it’s going to adversely impact the business case.

Battery life will be more significantly affected by factors such as operating temperature, SOC window, and charge time, which need to be examined with more advanced models that simulate thermal and electrochemical characteristics. At About:Energy we provide these models via The Voltt – our software platform featuring advanced battery data and models to streamline development.

The aerospace industry is still catching up with the automotive industry in terms of skills and expertise. But they have very aggressive entry-into-service (EIS) timelines to meet and a large order book to fill. Our library of models and datasets provides a resource for examining essential system requirements and generating innovative ideas for battery systems (including those for EVTOLs). It facilitates the assessment of various cell chemistries, designs, and configurations, aiding in the decision-making process to enhance battery system efficiency, reduce costs, and ensure safety.

Developing cutting-edge eVTOL battery packs requires a delicate balance of expertise in advanced battery technology, precise system requirements, and innovative engineering principles. At About:Energy, our mission is to empower the entire eVTOL ecosystem – from cell manufacturers to aircraft designers and battery system engineers. We provide the tools and insights needed to make data-driven decisions, accelerating the development and deployment of next-generation eVTOL battery solutions that push the boundaries of electric aviation.

Article by Yashraj Tripathy – Head of Product at About:Energy.