Advanced Construction Robotics launches TyBOT 3.0

Advanced Construction Robotics (ACR), a trailblazer in the world of construction technology, is making headlines once again.

The company has announced that its third-generation rebar tying robot, TyBOT 3.0, is now available for purchase, marking a significant shift from its previous Robot as a Service (RaaS) model.

With this game-changing development, ACR aims to empower construction firms with cutting-edge automation, boosting efficiency, safety, and productivity on job sites across the globe.

TyBOT 3.0: A New Era in Construction Robotics

The construction industry is no stranger to challenges, from labour shortages to tight project deadlines. ACR’s TyBOT 3.0 addresses these issues head-on, offering a robust and reliable solution that redefines rebar installation. The robot is now available for order with delivery slated for Q1 2025, giving contractors a chance to integrate this advanced technology into their operations sooner than ever.

Stephen Muck, Founder and Executive Chairman of ACR, emphasised the broader impact of this move: “Our success in the pursuit of automating construction equipment is not just an evolution for ACR; it is a transformative step for the entire construction industry. Offering TyBOT for sale represents our commitment to creating disruptive solutions that will redefine how the world builds, driving unprecedented efficiency, safety, and innovation across a wider range of construction applications.”

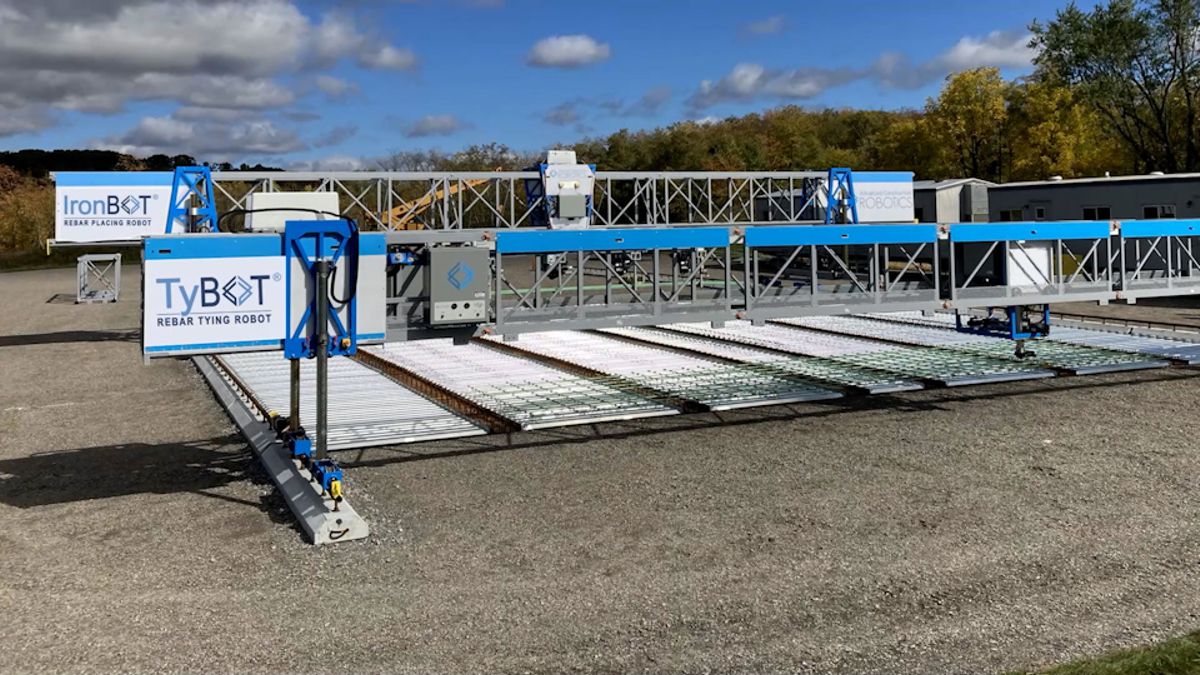

TyBOT 3.0 isn’t just another tool; it’s a revolution in construction robotics. Priced from $425,500 for models capable of up to 67 feet widths, and $455,500 for the expanded 117 feet versions, TyBOT’s price includes comprehensive training and support from ACR. This ensures that customers can confidently mobilise, configure, and maintain the robot right from the start.

Additionally, ACR’s Service Platform Subscription offers access to a live data portal, providing valuable insights into rebar installation operations and updates from ACR’s engineering team.

Boosting Productivity with Advanced Features

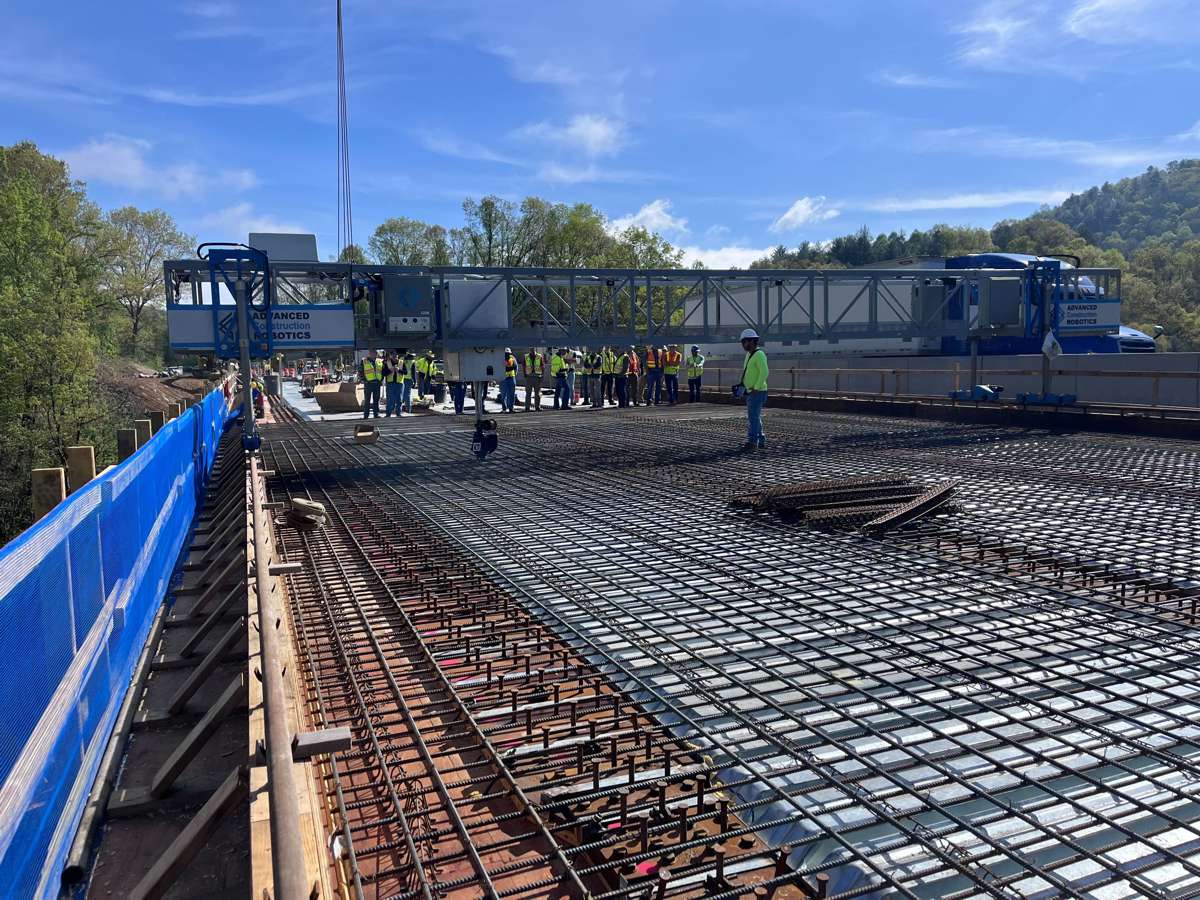

TyBOT 3.0 brings an impressive suite of enhancements that make it a must-have for modern construction projects. Its advanced automation features mean it can self-navigate, self-tie, and operate without the need for programming or input from BIM plans, making it incredibly user-friendly. For projects beyond traditional bridges, TyBOT offers multiple modes of travel and an optional carry function to efficiently transport materials to crew members on site.

Danielle Proctor, President and CEO of ACR, highlighted TyBOT’s impact on the industry: “With over 65 field deployments nationwide, TyBOT has proven that it provides customers at least 25% savings in their installation operations and is quickly becoming an accepted tool of the trade by rodbusters. We’ve seen a tremendous increase in demand for TyBOT as well as our second product, IronBOT®, the Rebar Placing Robot.”

IronBOT, TyBOT’s companion, lifts, carries, and places rebar, working in tandem with TyBOT to halve rebar installation schedules. Together, these robots offer a comprehensive solution to the skilled labour shortage plaguing the construction industry, providing firms with the means to meet growing demand, reduce scheduling risks, and significantly improve on-site safety.

From RaaS to Direct Sales: A Strategic Shift

Previously available exclusively through ACR’s Robot as a Service model, TyBOT’s transition to direct sales marks a strategic evolution in ACR’s business model. This shift reflects the growing confidence in the maturity and reliability of ACR’s products, developed to meet real-world construction challenges head-on.

“Our continued planned evolution from product design and adoption through RaaS to offering our BOTs for purchase reflects our confidence in our team’s ability to quickly provide mature products that reliably solve real-world problems,” said Proctor. “We look forward to customers fully integrating our solutions into their operations, providing enhanced productivity and safety using modern tools for a modern workforce.”

This change also signals a broader trend in the construction robotics market, as firms look for long-term investments that can be fully integrated into their operations. By purchasing TyBOT outright, contractors gain more control over their equipment, allowing them to maximise usage, optimise workflows, and adapt the technology to suit specific project needs.

The Business Case for TyBOT: Efficiency, Safety, and Cost Savings

One of the standout benefits of TyBOT is its ability to drastically cut rebar installation times, providing up to 25% savings in operations. This is particularly valuable in an industry where time is money, and delays can lead to costly overruns. By automating repetitive tasks, TyBOT frees up human workers to focus on more complex and critical aspects of construction, enhancing overall productivity.

Furthermore, TyBOT’s precision reduces the likelihood of errors, which not only improves the quality of the work but also enhances safety on-site. With fewer workers required to be directly involved in high-risk rebar tying tasks, the potential for accidents decreases, making TyBOT not just a tool of efficiency but a crucial asset for safer construction environments.

TyBOT’s adaptability is another key advantage. The robot’s ability to self-navigate and self-tie without the need for pre-programming or BIM inputs makes it a versatile solution for a variety of construction settings. Whether it’s a major bridge project or a complex urban development, TyBOT’s flexibility allows it to be deployed effectively across different types of jobs, making it an invaluable tool for contractors looking to diversify their capabilities.

Meeting Industry Demand and Filling the Labour Gap

The construction industry has long grappled with a skilled labour shortage, a challenge that has only been exacerbated by recent global events. ACR’s robotic solutions offer a clear path forward, addressing this gap by providing automated systems that can perform labour-intensive tasks with greater speed and consistency than human workers.

Stephen Muck underscores the transformative potential of TyBOT and IronBOT: “Our robots give construction firms the ability to consistently meet growing demand, reduce scheduling risks and improve safety. TyBOT® and IronBOT® are not just products; they are part of a broader strategy to modernise the construction workforce, equipping teams with the tools they need to succeed in today’s competitive market.”

The impact of these innovations is already being felt on job sites across the country, with firms reporting increased productivity, reduced costs, and a newfound ability to take on more projects without the strain of finding additional skilled labour. As the construction industry continues to evolve, the role of robotics will only grow, and ACR is positioned at the forefront of this revolution.

Looking Ahead: A Future of Automated Construction

As TyBOT 3.0 becomes available for purchase, the construction industry is witnessing a pivotal moment in its evolution. ACR’s commitment to providing cutting-edge solutions that address real-world challenges is not just changing how construction is done today; it’s setting the stage for the future of the industry.

With advanced robotics like TyBOT and IronBOT leading the charge, construction firms have the opportunity to redefine their operations, embrace new efficiencies, and enhance the safety and quality of their work. For those ready to invest in the future, TyBOT 3.0 isn’t just a robot—it’s a game-changer.