A Guide to Hardhats and Head Protection for the Construction Industry

As part of Construction Safety Month at Highways.Today, we delve into one of the most crucial aspects of workplace safety: hardhats and head protection.

Whether you’re overseeing a bustling site or handling materials on the ground, safeguarding workers from head injuries is non-negotiable. This guide explores everything you need to know about hardhats, from international standards and colour codes to future innovations, providing a valuable resource for the construction industry.

The Importance of Hardhats in Construction

Hardhats are more than just a uniform requirement; they’re lifesavers. According to the Health and Safety Executive (HSE) in the UK, falling objects and head injuries rank among the top causes of workplace fatalities in construction. With heavy machinery, elevated workspaces, and unpredictable site conditions, the risks are ever-present. Across the Atlantic, the U.S. Bureau of Labor Statistics (BLS) underscores the severity of the issue, noting that head injuries account for thousands of workplace accidents annually. Shockingly, many of these injuries could have been prevented with proper protective gear.

But what exactly makes a hardhat indispensable? These essential pieces of equipment are engineered to absorb and redistribute the impact of falling objects, effectively shielding the wearer from potentially catastrophic injuries. By doing so, they don’t just protect individuals; they foster a culture of safety and accountability on construction sites. Modern hardhats have evolved significantly, moving beyond basic protection to incorporate cutting-edge materials and advanced technologies. Features like ventilation for comfort during long hours, impact sensors to monitor hardhat integrity, and improved suspension systems have made today’s hardhats both functional and user-friendly.

Furthermore, they play a pivotal role in compliance with safety regulations worldwide. By meeting established standards, hardhats ensure not just individual protection but also organisational adherence to legal requirements. This combination of personal and collective safety underscores their significance in the construction industry, highlighting why no site can afford to overlook the importance of robust head protection.

International Standards for Hardhats

Navigating safety standards can be a maze, but understanding them is vital for compliance and worker safety. Here’s a snapshot of international requirements:

USA OSHA Compliance: The Occupational Safety and Health Administration mandates that hardhats meet ANSI Z89.1 standards. These classify hardhats into different types and classes based on the type of impact and electrical insulation they provide:

- Type I: Protects against impacts on the top of the head.

- Type II: Offers lateral protection, guarding against impacts to the side, front, and back.

- Classes G, E, and C: Define the level of electrical insulation, with Class E providing the highest protection.

United Kingdom

- BS EN 397: The British standard outlines basic requirements, including shock absorption, resistance to penetration, and compatibility with other PPE. It ensures that all hardhats meet stringent safety criteria to withstand the demands of a construction environment.

- BS EN 12492: Specific to climbing helmets, often used in high-access or rope work environments, this standard ensures protection against lateral impact and retention system effectiveness. These helmets are particularly vital in tasks requiring agility and stability in precarious positions.

Europe and Beyond

European standards, like EN 14052, offer high-performance specifications for industrial helmets, focusing on enhanced shock absorption and side-impact protection. These standards are particularly suited for environments where falling objects and lateral impacts are frequent concerns. Meanwhile, Australia and New Zealand follow AS/NZS 1801, which includes additional tests for extreme weather conditions, ensuring compliance with region-specific needs.

The wide variety of standards reflects the diverse challenges construction workers face globally. Whether it’s a high-altitude project in the Alps or a sun-scorched site in Australia, adherence to these regulations ensures consistent worker protection. For multinational construction companies, aligning with local standards is crucial for seamless operations and legal compliance.

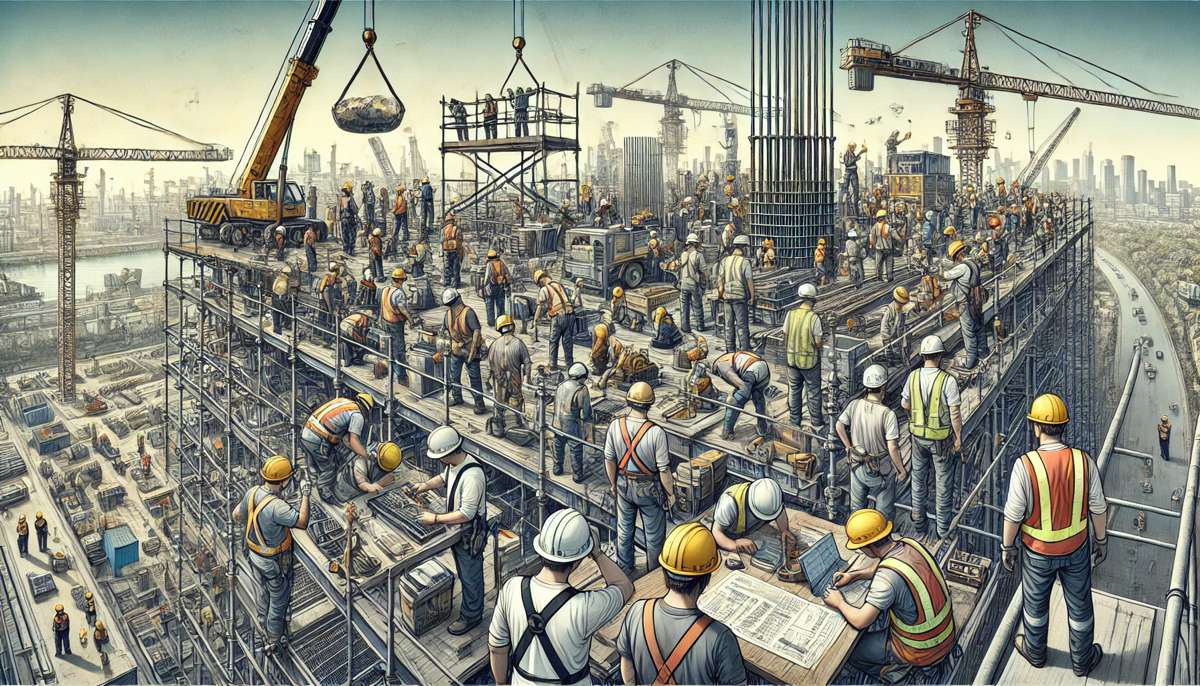

Decoding Hardhat Colours in the UK

Ever noticed the rainbow of hardhats on a construction site and wondered what they signify? In the UK, hardhat colours often indicate roles and responsibilities, promoting order and safety:

- White: Site managers, engineers, and supervisors

- Blue: Site visitors and new workers

- Green: First aiders and safety officers

- Yellow: General labourers and earthmoving operators

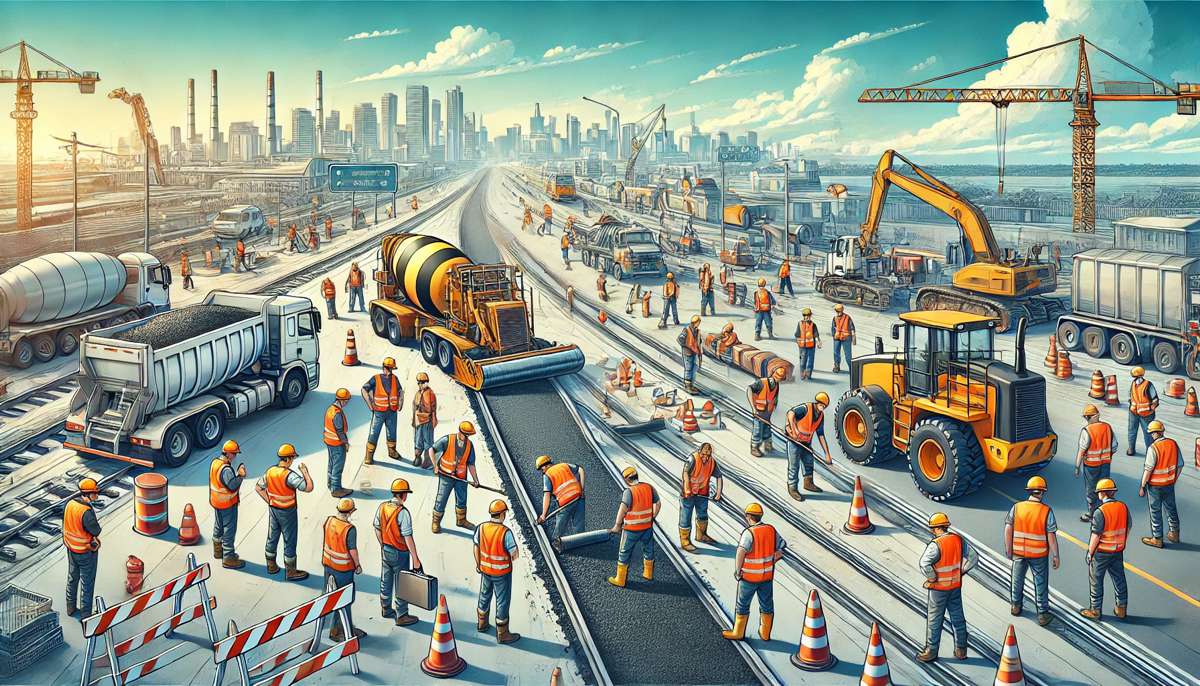

- Orange: Road crews and signal workers

- Black: Site forepersons or specific contractors

- Pink: Sometimes issued as a spare or for awareness initiatives

While not legally enforced, adhering to these conventions fosters better communication and coordination on-site. The visual cue of a colour-coded system helps workers identify key personnel at a glance, enhancing both safety and efficiency. For instance, spotting a green hardhat during an emergency quickly directs attention to a first aider, potentially saving precious seconds.

Types of Hardhats

Hardhats come in various styles, each suited to specific tasks and environments:

- Standard Construction Hardhats: These are the most common and offer basic protection from falling objects and debris. Lightweight and ventilated options improve wearer comfort during long shifts. Often designed with polyethylene shells and adjustable suspensions, they balance cost-efficiency with reliable performance.

- Climbing Helmets: Favoured for high-access work, these helmets come with chin straps to ensure stability during precarious tasks. Their design often complies with EN 12492 standards, offering superior lateral impact protection. These helmets are ideal for scaffolders, rope access technicians, and others working at dizzying heights where a traditional hardhat might fall off.

- Wide Brim Hardhats: Ideal for outdoor projects, these hardhats shield workers from sun exposure and rain, making them a popular choice for roadwork and large-scale projects. They also provide extended protection to the neck and shoulders, reducing the risk of sunburn and heat-related illnesses during long outdoor shifts.

Enhancing Hardhats with Attachments

Modern construction sites demand versatility, and hardhats have evolved to meet these needs with a range of attachments:

- Visors and Face Shields: For eye and face protection from sparks, splinters, or harmful UV rays. These attachments are often made from durable polycarbonate materials, ensuring clear vision without compromising safety. For added versatility, some models come with anti-fog and anti-scratch coatings, making them suitable for challenging environments.

- Hearing Protection: Integrated earmuffs or clips for attaching earplugs. Noise-induced hearing loss is a growing concern on construction sites, and combining head and ear protection ensures workers are shielded from high decibel levels while maintaining comfort. Advanced models even feature noise-cancelling technology.

- Headlamps: Hands-free illumination for low-light environments. These are especially useful for underground projects or during night shifts. Adjustable brightness levels and rechargeable battery options make them increasingly popular. Some headlamps even come with motion sensors, enabling automatic on/off functions to conserve energy.

- Communication Systems: Built-in radios or Bluetooth devices for seamless communication on large sites. These systems reduce the need for hand-held radios and keep workers connected at all times. Modern integrations also allow for noise-cancelling microphones and compatibility with other site communication tools, enhancing overall productivity and safety.

- Cooling Liners: To combat heat stress during summer months. These liners are often infused with advanced cooling gels or moisture-wicking fabrics that keep workers cool and comfortable. Some models are reusable, requiring just a quick soak in water to reactivate their cooling properties, making them ideal for long, hot workdays.

Beyond these standard attachments, innovative options are constantly being introduced to address specific site needs. For instance, helmets with built-in cameras are gaining traction, allowing for real-time video documentation or remote site monitoring. Solar-powered attachments are also emerging, offering eco-friendly solutions for powering integrated devices like lights or sensors.

These add-ons not only enhance the functionality of a standard hardhat but also ensure that workers are well-equipped to handle the diverse and evolving challenges of modern construction sites. By investing in such versatility, employers can significantly boost safety, efficiency, and morale on their projects.

Going Beyond Basic Protection

Hardhats have come a long way from their rudimentary beginnings. Today, innovative features offer enhanced safety and comfort:

- MIPS (Multi-directional Impact Protection System): Originally developed for sports helmets, MIPS is now being adopted for industrial use. It reduces rotational forces during angled impacts, significantly lowering the risk of traumatic brain injuries.

- High-Visibility Strips: Reflective materials improve visibility in low-light or high-traffic environments.

- Impact Sensors: Some advanced models include sensors that alert supervisors if a hardhat has sustained a significant impact, ensuring it’s replaced promptly.

- Adjustable Suspension Systems: Customisable fittings provide better stability and comfort, encouraging consistent use.

Hardhat Manufacturers

Several manufacturers lead the way in designing innovative, reliable, and industry-compliant hardhats.

Here are some of the key players:

- 3M: Known for its advanced personal protective equipment, 3M offers hardhats with cutting-edge features like integrated face shields, vented designs, and innovative suspension systems. Their helmets are widely recognised for combining comfort with superior safety standards.

- Honeywell: A global leader in industrial safety, Honeywell produces a range of hardhats tailored for various industries, including construction. Their helmets often incorporate advanced impact protection technologies and ergonomic designs for prolonged wear.

- MSA Safety: With over a century of expertise, MSA Safety is synonymous with quality and innovation. Their V-Gard series is a staple on construction sites, offering durability, adaptability, and compliance with international safety standards.

- Pyramex: This manufacturer is renowned for offering cost-effective solutions without compromising quality. Pyramex hardhats are especially popular for their lightweight construction and excellent ventilation features.

- KASK: A premium option in the market, KASK specialises in safety helmets for both industrial and recreational use. Their climbing helmets, in particular, stand out for their advanced safety certifications and stylish designs.

- Bullard: Known for pioneering hardhat designs, Bullard continues to innovate with helmets that focus on comfort, durability, and integration with modern attachments like communication devices and cooling systems.

These manufacturers not only set the benchmark for safety and design but also continue to push the boundaries of what hardhats can achieve. Whether through improved materials, smarter features, or eco-friendly production methods, they are shaping the future of head protection.

The Future of Hardhats

The construction industry’s focus on safety and technology is paving the way for smarter, more effective head protection. This dynamic evolution promises to address not only current challenges but also anticipate future needs on job sites. Here’s a detailed look at what’s on the horizon:

- Smart Helmets: Equipped with augmented reality (AR) technology, these helmets are transforming how workers interact with their environments. By overlaying digital information directly onto the wearer’s field of view, smart helmets can display blueprints, provide step-by-step instructions for complex tasks, and even identify hazardous areas in real-time. Some advanced models may include voice-controlled interfaces, allowing workers to access information hands-free, further enhancing efficiency and safety.

- Biometric Monitoring: Built-in sensors embedded in future hardhats could revolutionise how worker health is managed on-site. These sensors could monitor vital metrics such as heart rate, hydration levels, body temperature, and even blood oxygen levels. This data would allow supervisors to detect early signs of fatigue, dehydration, or heat stress, ensuring timely interventions that prevent accidents. Moreover, integrated health monitoring could support long-term worker wellness initiatives.

- Enhanced Communication Systems: Future hardhats may feature integrated wireless communication networks, enabling seamless interaction between workers and supervisors. These systems could include real-time video feeds, enabling remote project managers to monitor progress or provide immediate guidance. Noise-cancelling microphones and speakers would ensure clear communication, even in noisy construction environments.

- Eco-friendly Materials: As sustainability becomes a cornerstone of modern industries, hardhat manufacturers are exploring eco-conscious options. Biodegradable plastics and recycled materials could significantly reduce environmental impact. Some prototypes also incorporate solar panels to power built-in devices like sensors or lights, adding a layer of renewable energy utilisation to construction sites.

- Customisable Designs: Emerging technologies in 3D printing could enable personalised hardhats tailored to individual workers. These custom fits would not only enhance comfort but also ensure better protection by eliminating gaps or pressure points. Additive manufacturing could also facilitate rapid production of specialised helmets for unique projects or environments.

- Integrated Safety Features: Future innovations might include impact recording systems that document every significant blow to a hardhat. This data could be used to evaluate the severity of incidents, helping safety managers identify areas for improvement. Smart helmets could also feature automatic alerts to nearby workers when a colleague experiences an accident, speeding up response times.

The potential of these advancements reflects the construction industry’s commitment to prioritising worker safety and operational efficiency. By embracing cutting-edge technologies and sustainable practices, the next generation of hardhats promises to be smarter, greener, and more reliable than ever before.

Hardhat Safety in Numbers

Statistics paint a vivid picture of just how critical proper head protection is across the construction industry:

- United Kingdom: Over 10% of non-fatal construction injuries are attributed to head injuries, according to the Health and Safety Executive (HSE). These figures underscore the persistent risks workers face on sites with falling debris, heavy machinery, and structural hazards.

- United States: The Bureau of Labor Statistics (BLS) estimates that up to 70% of recorded head injuries in construction could have been prevented with proper use of hardhats. This staggering statistic highlights the life-saving potential of ensuring every worker adheres to personal protective equipment (PPE) policies.

- Global Trends: Internationally, workplaces that enforce robust PPE regulations, including mandatory hardhat use, report accident rates that are significantly lower compared to those with lax enforcement. In countries where compliance is particularly strong, some industries have seen a reduction in head injuries by as much as 50% over the past decade.

- Economic Costs: Beyond the human impact, head injuries contribute substantially to economic losses in the sector. Medical costs, compensation claims, and project delays can run into the millions annually, making preventive measures like hardhat mandates a cost-effective strategy.

- Cultural Shifts: Companies with a strong emphasis on PPE, including hardhat use, often report improved workplace morale and safety awareness. Such cultural shifts not only protect workers but also bolster productivity by reducing downtime from accidents.

By examining these numbers, it’s clear that enforcing the consistent use of hardhats is a cornerstone of effective safety protocols. A focus on compliance, education, and innovative protective gear could help turn these statistics into success stories for the construction industry worldwide.

Making Safety a Priority

Hardhats are far more than a box to tick on a safety checklist—they’re a cornerstone of effective workplace safety and an invaluable investment in your team’s wellbeing. Beyond compliance with legal standards, they symbolise a company’s commitment to protecting its workforce and fostering a culture of safety. When workers see their employers prioritising their protection with state-of-the-art gear and proper education, it boosts morale and confidence on-site.

Understanding the diverse standards, styles, and innovative features of hardhats is essential for construction professionals. Modern advancements—from MIPS technology to biometric monitoring—provide unprecedented levels of protection and comfort, ensuring that safety equipment evolves alongside the increasingly complex challenges of today’s construction environments. Embracing these innovations can transform a site into not just a workplace but a benchmark for safety excellence.

Accidents can and do happen. However, with the right combination of high-quality gear, proactive safety training, and a commitment to innovation, the construction industry has the tools to drastically reduce preventable injuries. Every hardhat worn represents a step closer to safer, more efficient job sites, and that’s a future worth investing in.