Pipebursting Technology Makes a Comeback in the UK with AMP8

In a sector where innovation is often tied to the flash of new tech, one veteran method is making a strong return. Pipebursting, a trenchless pipe replacement technique that first caught attention back in the late 1970s, is finding itself back in the limelight thanks to the arrival of AMP8 and new regulatory guidance from Ofwat.

At the heart of this resurgence is the TRACTO GRUNDOBURST system, a machine that has been redefining how water utilities approach infrastructure upgrades without digging up half the street. Originally developed by TRACTO in response to requests from British Gas and Severn Trent Water, the method was born out of a pressing need: replace ageing underground pipes without bringing chaos to communities.

Why AMP8 Changes Everything

Ofwat’s AMP8, launched in April 2025, marks the start of a fresh five-year Asset Management Period. But this time, the regulator has made its intentions crystal clear. Utility companies are expected to prioritise trenchless technologies for pipe replacement projects.

The shift is about more than just efficiency. It’s a response to growing public frustration with endless roadworks and urban disruption. Ofwat’s directive mandates the use of pipebursting wherever it makes sense, particularly on mains replacement schemes. It’s a nod to smarter, faster, and less intrusive infrastructure strategies.

The impact on the industry? Immediate. Contractors are rushing to adapt, and companies like TRACTO are reporting a noticeable uptick in demand for systems like the GRUNDOBURST.

How Pipebursting Works

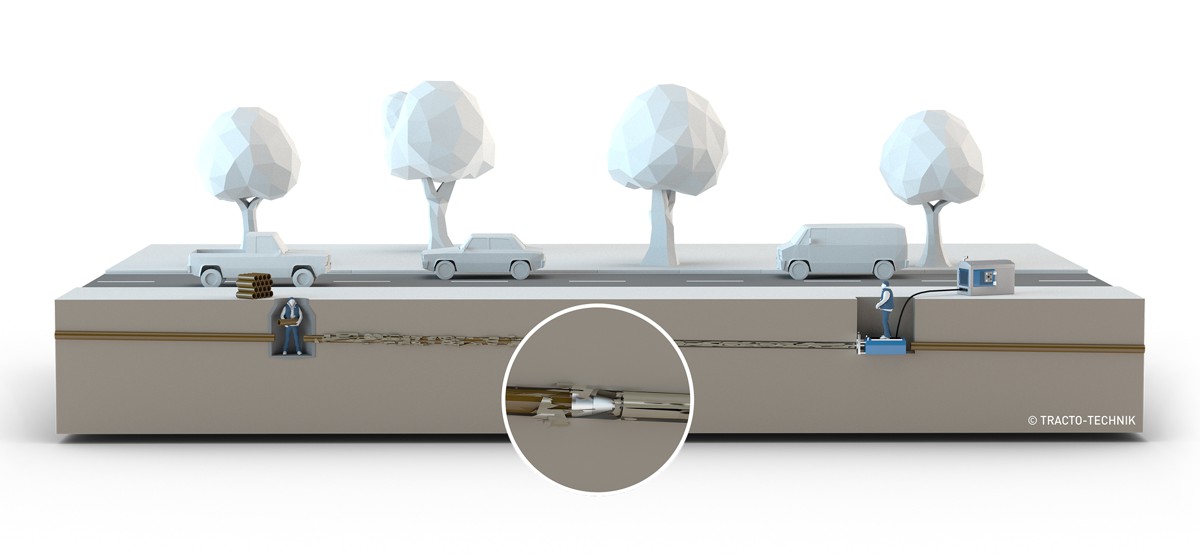

Put simply, pipebursting is the practice of replacing underground pipelines without the need for traditional excavation. The process involves inserting a bursting head through an existing pipe, fracturing it as it moves forward. In its wake, a new pipe – usually high-density polyethylene (HDPE) – is pulled into place.

The beauty of this method lies in its minimal surface impact. Typically, only two pits are required: one to launch the burster and another to receive it. The result is a quicker turnaround, reduced noise, far less dust, and minimal spoil removal.

Moreover, the technique isn’t just good for like-for-like replacements. If increased capacity is needed, the system can install a larger pipe in the same space, making future-proofing part of the package.

A Flexible Workhorse

TRACTO’s GRUNDOBURST isn’t your average machine. It’s a purpose-built powerhouse that comes in six models, ranging from the compact 400G to the mighty 2500G. Pulling capacities vary from 40 to 250 tonnes, and pipe diameters of up to 900mm are well within its wheelhouse.

But it’s not just about brute force. What sets GRUNDOBURST apart is its innovative ladder rod system. Rather than screwing rods together, operators use a hook mechanism that offers both speed and lateral flexibility. That means the system can work along curved pipe alignments – a significant advantage in urban settings.

Add to that TRACTO’s own set of specialised accessories and bursting tools, and you’ve got a system that can adapt to just about any scenario.

Safety hasn’t been overlooked either. One standout feature is the red safety guard at the rear, preventing anyone from standing in the danger zone behind the machine while rods are being retrieved.

Environmental and Social Benefits

Beyond the technical perks, trenchless technology brings a raft of social and environmental benefits. Less spoil means fewer truck movements. Shorter job durations mean less disruption to traffic, businesses, and local residents.

Then there’s the carbon angle. Fewer diggers, less dust, and reduced fuel use all contribute to a lower carbon footprint. This aligns neatly with the broader sustainability goals that utility providers are increasingly being judged on.

A study by the UKSTT (UK Society for Trenchless Technology) found that trenchless techniques could cut greenhouse gas emissions by up to 75% compared to traditional open-cut methods. That makes pipebursting not just a clever engineering solution, but a strategic environmental one.

Endorsement by the Industry

The industry has been quick to respond to the changing tide. Water companies across the UK are now reviewing capital plans for AMP8 with a trenchless-first mindset.

Paul Harwood, a senior utility contractor, remarked: “Ofwat’s new direction has encouraged us to think differently. Pipebursting using GRUNDOBURST ticks all the boxes: it’s fast, clean, and significantly less disruptive for our clients.”

Manufacturers like TRACTO are also doubling down on customer support, offering training, maintenance services, and tailored advice to contractors adapting to the new norm.

Roger Wahl from TRACTO noted: “We’re seeing unprecedented interest in GRUNDOBURST. The industry’s appetite for trenchless is stronger than ever, and our technology is perfectly placed to meet that demand.”

What’s Next for Pipebursting?

With AMP8 setting the tone, the next six years will likely see pipebursting become the default choice for pipe replacements in urban areas. But there’s also room for expansion into sewer systems and gas pipeline renewals, where similar principles apply.

TRACTO’s future roadmap hints at more automation and digital integration, including remote diagnostics and cloud-based performance tracking. These advancements could make systems like GRUNDOBURST even more compelling for forward-thinking contractors.

Expect to see further investment from public utilities as they work towards long-term resilience targets without compromising sustainability or customer satisfaction.

A Smarter Way to Modernise Infrastructure

Pipebursting isn’t just back – it’s back with purpose. With policy now squarely behind trenchless solutions and technology leading the charge, we’re entering a phase where civil engineering can finally leave behind the jackhammers and bulldozers in favour of smarter, cleaner, and more efficient alternatives.

The message is clear: dig less, deliver more.