Hydrogen Breakthrough Could Revolutionise Green Metal Production

A pioneering study from Binghamton University and Brookhaven National Laboratory is challenging decades-old assumptions in the world of metal production.

Published in Nature, the research shines a light on the differences between two common gases used to reduce metal oxides — hydrogen and carbon monoxide — with findings that could reshape how industries produce metals for everything from bridges and buildings to semiconductors and quantum materials.

The study reveals that hydrogen, often overlooked in favour of carbon monoxide, has distinct advantages in accelerating metal oxide reduction while lowering carbon emissions. This new understanding opens the door to faster, cleaner and more energy-efficient production.

“The goal is to drive this reduction process using less energy, at lower temperatures, and with minimal carbon dioxide emissions,” explained Guangwen Zhou, a SUNY distinguished professor at Binghamton University. “Our study offers insights that can help guide the choice of gases to accelerate reaction kinetics, making metal extraction faster, cleaner and more energy efficient.”

Why hydrogen changes the game

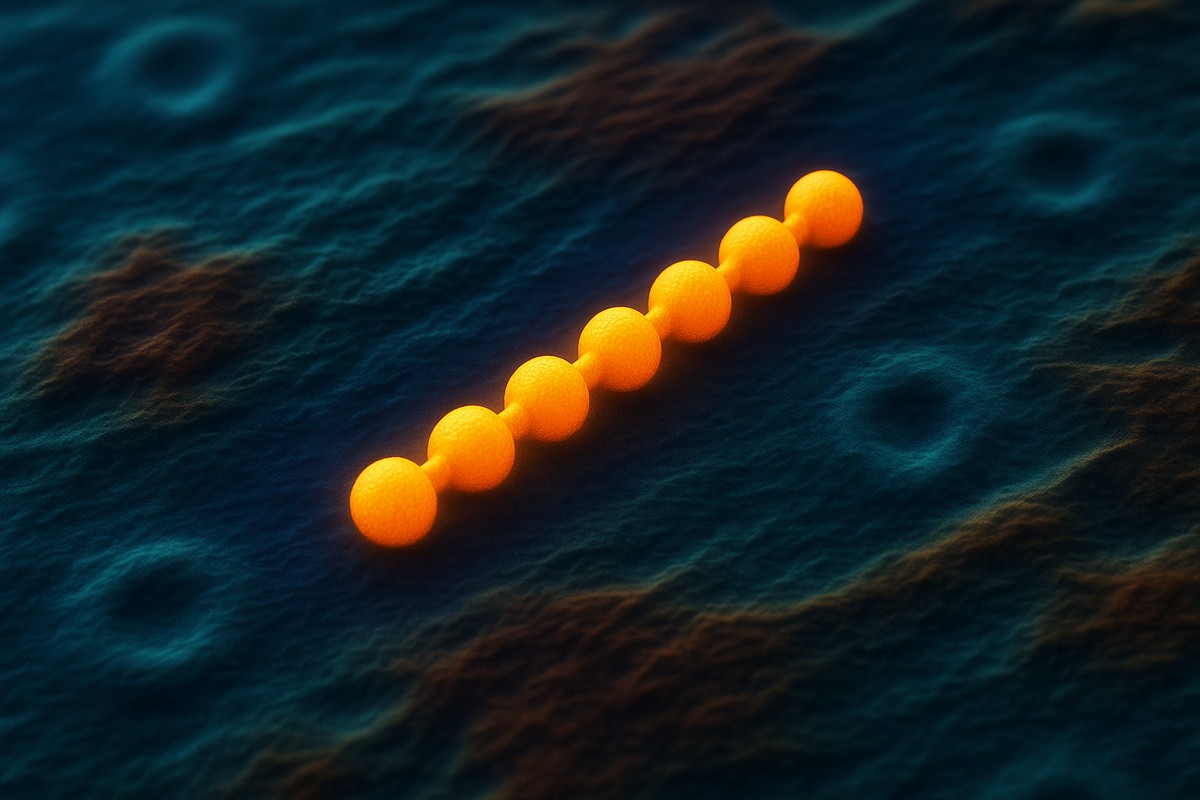

Traditionally, both hydrogen and carbon monoxide have been treated as interchangeable reductants. However, Zhou’s team found that their reaction pathways are far from identical. When carbon monoxide is used to reduce nickel oxide, a thin metallic crust forms on the surface, blocking catalytic activity and slowing the reaction. This not only increases energy requirements but also locks in inefficiencies.

Hydrogen behaves differently. It allows oxygen vacancies to migrate deeper into the oxide, enabling metal formation throughout the interior. The surface remains catalytically active, supporting continuous reactions.

“If we use hydrogen, we can facilitate this process,” Zhou said. “For industrial applications, we can have catalyst regeneration without interrupting the catalytic process.”

Importantly, hydrogen produces water vapour instead of carbon dioxide — a significant environmental benefit.

Implications for sustainable industry

The environmental impact of carbon monoxide use is a growing concern, especially as heavy industries come under increasing scrutiny for their carbon footprints. Switching to hydrogen could significantly cut emissions while improving throughput.

Hydrogen’s ability to keep catalysts active and even promote self-healing in certain reactions could extend equipment life, further reducing operational costs. This positions hydrogen as a critical player in sustainable metallurgy.

Judith Yang, a scientist at Brookhaven’s Center for Functional Nanomaterials, emphasised the paradigm shift: “With these new tools and insights, we’re developing a new way of understanding oxide reduction, moving beyond the standard explanations still taught in classrooms.”

Advanced tools unlocking atomic secrets

The team’s findings were made possible by cutting-edge instruments at Brookhaven National Laboratory, including an environmental transmission electron microscope (TEM) capable of observing reactions atom by atom in real time.

“There are only a few of these tools with such capability in the entire country,” Zhou said. Complementary synchrotron X-ray diffraction (XRD) at the National Synchrotron Light Source II provided large-scale data, creating a complete picture of reaction dynamics.

Lu Ma, lead beamline scientist at Brookhaven, noted: “In-situ TEM reveals whether nucleation initiates on the surface or within the interior at the nanoscale, while ensemble XRD offers bulk-scale insights. Together, these methods deliver consistent evidence across different length scales.”

A long-standing collaboration

This research builds on nearly two decades of collaboration between Binghamton University and Brookhaven. Many of Zhou’s students gain invaluable hands-on experience at Brookhaven, working with highly complex equipment in a supportive environment.

Doctoral student Xiaobo Chen reflected on the process: “We cannot guarantee results every time, but CFN and NSLS-II are friendly environments where we have many opportunities to try.”

The work not only advances industrial practices but also fuels scientific curiosity and inspires technological innovation. Yang highlighted this point: “It’s the science that Xiaobo and Professor Zhou are doing that motivates the next generation of infrastructure development.”

Looking to the future

With nickel oxide studies complete, Zhou’s team is turning their attention to other metals, including copper and iron oxides — materials that harken back to the Bronze and Iron Ages.

Yang found this historical link fascinating: “We’re finding new fascination in what’s defined the materials ages of human history.”

If the research continues to prove hydrogen’s superior performance, industries could see a major shift in how they approach metal production. The potential benefits — lower emissions, reduced energy consumption, faster processing times and longer-lasting catalysts — are too significant to ignore.

Moving towards a cleaner metals industry

As the pressure mounts for industries to decarbonise, the findings from Binghamton and Brookhaven could not be timelier. Hydrogen’s ability to make metal production greener and more efficient may prove instrumental in achieving global sustainability goals.

The path forward will require investment in hydrogen infrastructure, adaptation of industrial processes, and continued research into material-specific behaviours. But the payoff — a cleaner, faster, more resilient metals industry — offers a compelling incentive for change.