DuAlumin‑3D Breaks Boundaries in Automotive and Aerospace Materials

From Oak Ridge National Laboratory’s labs to the engine bays and fuselages of the future, DuAlumin‑3D is redefining what aluminium alloys can do.

This cutting‑edge material isn’t just another incremental tweak; it’s a full‑blown leap forward in additive manufacturing technology.

What Makes DuAlumin‑3D Stand Out

Developed by ORNL scientists, DuAlumin‑3D exhibits exceptional strength and resistance to deformation at elevated temperatures, surpassing all known aluminium alloys. Unlike conventional alloys that tend to crack during laser powder bed fusion, DuAlumin‑3D remains stable, allowing for more complex and durable designs.

Tests show it retains more than half its strength even at 300 to 315 °C and maintains microstructural stability up to 400 °C. That’s game‑changing for industries where heat is a formidable enemy—whether in automotive engine blocks or aerospace structures.

Lead researcher Alex Plotkowski summed it up: “DuAlumin‑3D performed exceptionally well in our evaluations. While our research focused on its use in high‑efficiency engines, it could also be used for lightweighting applications in aerospace and to optimise heat exchangers.”

The Additive Manufacturing Advantage

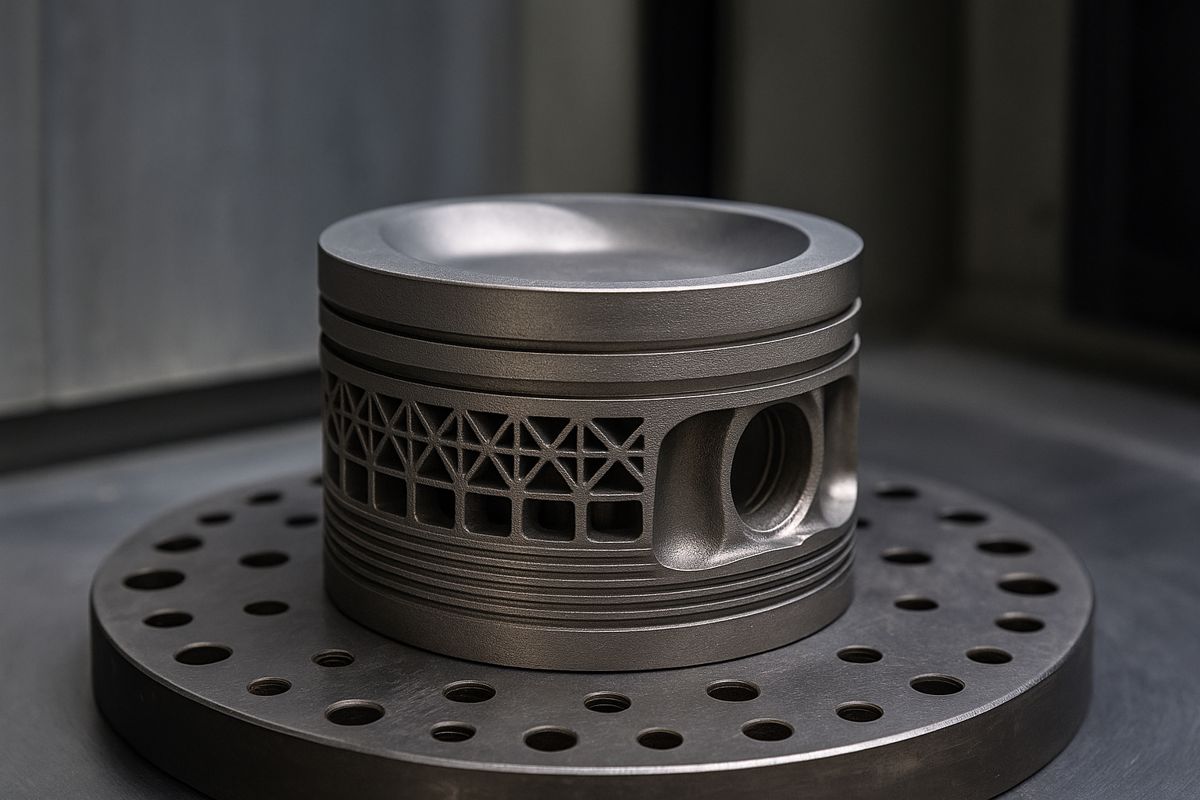

Traditional aluminium alloys are challenging to process through additive manufacturing due to cracking. DuAlumin‑3D’s unique formulation overcomes this by employing dual strengthening mechanisms—a dense nanoscale microstructure from rapid solidification during printing, and precipitate phases introduced through heat treatment.

Plotkowski explained: “Aluminium alloys were a really interesting problem space for us to work in… conventional alloys are challenging to process with additive manufacturing.” This breakthrough means engineers can now print high‑performance aluminium parts with far greater confidence in their durability and performance.

Proven in Engine Tests

ORNL didn’t stop at the lab bench. Researchers 3D‑printed pistons from DuAlumin‑3D and ran them through demanding four‑cylinder engine tests. The results? Outstanding performance under punishing thermal and mechanical loads.

Automotive giants are already taking note. General Motors is working on applications for lightweight, high‑efficiency V8 engines for medium‑duty trucks, while Honda Performance Development is exploring other potential uses.

As Plotkowski highlighted: “It was necessary to collaborate… ORNL can do this because we’re bringing together this diverse skillset.”

Industry Recognition

DuAlumin‑3D’s debut didn’t go unnoticed. In 2022, ORNL, GM, and Beehive3D scooped an R&D 100 Award—often called the “Oscars of Innovation”—for its extreme creep and fatigue resistance in high‑temperature service.

This accolade underscores the alloy’s transformative potential and its readiness for real‑world deployment.

Beyond Automotive

While the initial focus has been on high‑efficiency automotive engines, DuAlumin‑3D’s scope stretches much further. Aerospace applications are a natural fit, potentially replacing heavier and costlier titanium parts. The weight savings translate directly into reduced fuel consumption and lower emissions.

Its exceptional thermal and mechanical properties also make it a strong candidate for advanced heat exchangers and components in clean energy systems.

Industry Implications

For investors, DuAlumin‑3D offers a tangible path to market differentiation in sectors from trucking to aviation. Policymakers can view it as a tool for achieving transport emissions reductions through lightweight design.

Materials engineers and manufacturers gain a new weapon in overcoming the historic limitations of aluminium in additive manufacturing.

Looking Ahead with Confidence

DuAlumin‑3D is more than a laboratory curiosity—it’s a proven performer with the potential to become an industry standard. By combining lightness, strength, heat resistance, and printability, it addresses some of the toughest challenges in manufacturing today.

With partners like GM and Honda on board, and a track record of award‑winning innovation, ORNL’s alloy is set to play a defining role in the next generation of high‑performance automotive and aerospace components.