Digital Twins Are Transforming Global Infrastructure

Modern road infrastructure is undergoing a transformation at a breakneck pace, blending time-honoured asphalt with cutting-edge algorithms. Around the world, highways are becoming “smart,” integrating sensors, software, and real-time data to make journeys safer, faster, and more sustainable. This digital road infrastructure isn’t just shiny add-ons; it directly address pressing challenges like congestion, accidents, and aging infrastructure that traditional approaches alone can no longer solve.

As one industry executive put it: “We are not going to build our way out of the challenges we face, we are going to SMART our way out of it.” In other words, meeting goals such as safer and greener roads depends as much on digital innovation as on concrete and steel.

This global drive toward smarter highways marks a paradigm shift in how roads are planned, built, and managed. “We are at the beginning of a digital revolution in roads infrastructure and expect to see more change in the next decade than we have in the last century. This provides an opportunity to make our roads safer, improve customer experience for all, and support our plans for net zero,” observed Nick Harris, Chief Executive of National Highways in the UK. His words underscore the monumental scale of change underway. From intelligent traffic systems that predict jams before they form, to digital blueprints that simulate an entire road’s lifecycle, the road ahead is being reshaped by technology.

Digital Twins and BIM

To design the highways of tomorrow, engineers are increasingly turning to digital twins and Building Information Modelling (BIM). A digital twin is a dynamic virtual replica of a physical asset and in this case, a road or bridge that updates in real time with data about its condition and environment. Think of it as a living, evolving blueprint. BIM, meanwhile, is the process of creating rich 3D models packed with information on every component of a project. Together, these tools are revolutionising how we plan and design infrastructure.

In the past, planning a highway involved stacks of drawings and siloed teams working on separate pieces of the puzzle. Today, a digital twin brings everything into one cohesive model, allowing planners, engineers, and stakeholders to collaborate in a shared virtual space. Bibhuti Aryal, an industry director at Bentley Systems, describes digital twins as “the foundation of smarter decision-making,” enabling agencies to simulate scenarios and optimise designs throughout a road’s lifecycle. With a digital twin, teams can integrate geospatial maps, environmental data, and traffic forecasts into the design process from day one. This unified view helps ensure that new roads are not only technically sound but also environmentally and socially optimal.

Real-world examples illustrate the power of this approach. In London, the massive Elizabeth Line rail project leveraged advanced digital planning tools to perfect its design. “Using our traffic simulation capabilities and asset analytics, they were able to determine how best to design this new line,” Aryal recalls, noting that the digitally optimised plan reduced road traffic, cutting congestion and emissions in the city. Halfway around the globe in Singapore, planners have even created a digital twin of the entire city to monitor urban development and infrastructure needs in real time. These cases show how digital models help teams visualise complex projects, run “what-if” simulations, and catch design conflicts before they turn into costly onsite mistakes.

For road agencies, one of the biggest payoffs of BIM and digital twins is early risk mitigation. By visualising projects in 3D (and even 4D with the element of time), engineers can spot clashes and design errors long before construction begins. “You don’t want to find defects when the product is live. Similarly, addressing design issues early prevents delays and safety risks,” Aryal explains, likening proactive design reviews to catching software bugs in the requirements phase rather than after deployment. In practice, this might mean discovering that a planned overpass would conflict with an existing utility line before anyone pours concrete, an insight that digital models can reveal in minutes, saving months of trouble later.

BIM’s collaborative nature also breaks down traditional silos. Architects, civil engineers, and contractors can all work on the same model, updating it with their inputs. Everyone sees the latest changes, preventing misunderstandings. “Road projects involve multiple disciplines, geotechnical, geospatial, civil, structural, and these must work in sync. Digital twins let us see changes in real time, ensuring they’re addressed before construction,” Aryal notes. By sharing one source of truth, teams avoid the classic scenario of “version confusion” where one group is working off outdated plans. The result is more accurate designs and a smoother handoff to construction.

Smarter Bidding and Collaboration from the Start

Digital transformation isn’t just improving technical drawings, it’s also cleaning up the paperwork jungle of procurement and project management. The tendering phase of road projects, once dominated by paper plans and lengthy document submissions, is now embracing digital workflows. Detailed 3D models and data-rich proposals are replacing static blueprints in bid packages. This shift brings greater transparency and clarity to all parties competing for a contract.

With model-based tenders, contractors can explore a virtual road design and see quantities (like volumes of earthworks or materials) directly embedded in the model. This clarity reduces the guesswork that bidders often face. “When digital models embed relevant data, like materials and volumes, you can automate manual tasks (in estimating),” Aryal explains. Instead of each bidder interpreting drawings differently, everyone works from the same rich dataset. According to Aryal, this robust approach means “people bidding on the work can’t say, ‘Oh, I didn’t know that,’ and add contingency. You get more accurate cost estimates and stick to them.” In short, fewer surprises in bids lead to fairer prices and fewer disputes down the road.

Digital tendering also fosters collaboration through transparency. When an agency provides a complete digital context, including existing site conditions and even known defects, contractors can plan more confidently. One bridge project found that sharing a detailed model with bidders helped identify unnecessary work during the bid phase, saving millions before construction even started. Unified digital data environments (like Bentley’s SYNCHRO platform) allow owners, consultants, and builders to literally be on the same page (or rather, the same screen) from day one. Misunderstandings are minimised, and everyone can contribute suggestions to improve the plan. This level of openness builds trust and speeds up decision-making, a stark contrast to the old days when each stakeholder guarded their own set of documents.

Importantly, the benefits of these technologies shouldn’t be limited to only the biggest industry players. Aryal acknowledges that smaller contractors sometimes worry about the accessibility of fancy digital tools. “The future is already here, but it’s not evenly distributed. Smaller firms must have access to these technologies to remain competitive,” he says. Ensuring inclusivity means using open data standards and affordable platforms so that projects of all sizes, not just mega-projects, can reap the rewards of digital efficiency. Industry-wide collaboration, training, and perhaps government support will be essential to bring every firm (even a small local road paver) into the digital fold. After all, a rising tide of technology should lift all boats, not just the big ships.

From Simulation to Safer Sites

Once a road design is vetted and a contract awarded, the next challenge is turning plans into pavement. Here, too, digital technology is changing the game. Construction management software and 4D simulation tools allow project teams to rehearse the build virtually before anyone breaks ground. This concept of “building twice, first digitally, then physically” is enhancing safety, efficiency, and cost control on job sites.

A prime example is the use of Bentley’s SYNCHRO platform to create a virtual construction sequence. Planners can map out each day of work in a 3D timeline, where equipment will be, which sections of road will be closed, how materials will flow, and then watch this simulation play out on screen. It’s like a high-tech Gantt chart come to life. “Being able to simulate construction before crews break ground is invaluable,” Aryal says. By running different scenarios, the team can spot potential safety risks or conflicts in advance. For instance, a virtual run-through might reveal that two work crews were scheduled to overlap in a tight area, or that heavy machinery access was blocked by a planned temporary structure. These issues can then be resolved in the model, not in the field under rushed conditions.

This proactive approach paid off on a highway expansion in Minnesota, where digital rehearsals using SYNCHRO uncovered utility line conflicts early. Adjustments in the plan ended up saving $5 million and avoiding schedule delays. Instead of discovering the clash weeks into construction (with crews idling and costs mounting), the project team fixed it virtually and kept the real project on track. Aryal emphasises that “this proactive approach ensures you’re addressing issues in the design phase, not on the field.”

Beyond efficiency, virtual construction modeling is fundamentally about safety. When everyone on site can visualise the plan of attack, it reduces surprises that lead to accidents. Workers can be trained using the 4D model to understand where hazards might arise each day. In complex builds like multilevel interchanges or tunnels, these simulations are a boon for planning safe access and egress routes, sequencing heavy lifts, and keeping crews out of each other’s way. As Aryal succinctly puts it, “Virtual construction isn’t just about efficiency; it’s about safety.”

In the field, construction management software also delivers real-time updates that keep everyone aligned. Cloud-based platforms (such as Procore, Autodesk Construction Cloud, or Bentley’s suite) now let project managers, engineers, and site supervisors share progress instantly via tablets and smartphones. If a change is approved, say a design modification or a schedule shift, the digital model and task list update immediately for all users. “Being able to see the most up-to-date information, whether you’re in the field or the office, adds immense value,” notes Aryal. This connectivity means the crew pouring concrete has the latest specs, and the folks at headquarters see the on-site status in real time. No more version mismatches or delayed email chains, everyone works off the live model, greatly reducing rework caused by miscommunication.

Another benefit is the ability to track progress and productivity data as construction unfolds. Drones, cameras, and IoT sensors at sites can feed back into the project model, confirming what’s been built, measuring quantities, and flagging issues like equipment downtime. Modern construction management systems often include dashboards for cost tracking and schedule updates, automatically generated from site inputs. Leading contractors are embracing such tools to keep projects on-budget and on-schedule. In short, the dusty construction site is getting a digital overlay, bringing new levels of control and foresight to an industry historically plagued by cost overruns and change orders.

Intelligent Traffic Management

Once a road is opened to the public, the focus shifts to operations, keeping traffic flowing smoothly and responding rapidly to incidents. Here, Artificial Intelligence has emerged as a powerful ally for highway operators. Traditional traffic management centres rely on fixed timing plans and human controllers monitoring CCTV feeds. These methods leave blind spots and often react after congestion or accidents have already happened. AI aims to turn highway operations from a reactive endeavour into a proactive, predictive one.

How can AI help? By crunching vast streams of data from cameras, sensors embedded in pavement, connected vehicles, and even smartphone apps, AI algorithms can detect patterns and anomalies far faster than a person watching a bank of screens. For example, an AI system might notice vehicles in one stretch are braking hard and slowing unexpectedly, while overhead sensors detect an object on the road. The AI can instantly flag a likely incident, perhaps a fallen load or a crash, and alert operators within seconds, often before any driver manages to call it in. Early detection triggers quicker emergency response and warnings to other drivers, which can prevent secondary crashes. In fact, several highway agencies report that AI vision systems can spot incidents on camera feeds in the blink of an eye, outperforming human operators who might be looking elsewhere at that moment.

One compelling example comes from Japan, where highway authorities deployed AI to automatically detect wrong-way drivers on the expressways. With over 15,000 surveillance cameras to monitor, only AI could watch them all without fatigue. The system’s computer vision identifies a car moving against traffic and then immediately issues alerts with a voice warning in the errant driver’s vehicle (if connected), and pop-up alerts on nearby drivers’ navigation apps and on electronic road signs. This real-time response provides potentially life-saving seconds for correction or evasion. It’s a prime illustration of AI actively enhancing safety in a situation where human monitoring alone struggled to intervene quickly.

AI isn’t just about emergencies; it’s also optimizing everyday traffic flow. Smarter algorithms are now adjusting traffic signal timings and variable speed limits dynamically based on live conditions, rather than fixed schedules. By analysing data on traffic volumes, speeds, and even weather, AI-driven systems can, for instance, hold a green light a bit longer if they “see” a congestion building up, or pre-emptively slow down traffic upstream of a bottleneck to prevent stop-and-go waves. This kind of predictive traffic management has been piloted in places like Las Vegas and Nashville with promising results. In Las Vegas, an AI-based traffic control pilot reduced primary crashes by 17% by smoothing flow and reducing sudden stops. And in Nashville, the CIRCLES project demonstrated that when a small percentage of cars were AI-guided to adjust their spacing and speed, overall congestion and fuel consumption dropped markedly on the highway. AI essentially acts like a symphony conductor for traffic, orchestrating vehicles to behave in a more harmonious, efficient way.

With AI at the helm, incident response is also getting a boost. In the Netherlands, the road authority Rijkswaterstaat uses AI to guide where it positions its patrol and incident response units. By learning from historical crash data and current traffic patterns, the AI suggests stationing tow trucks or highway patrols at strategic spots before an accident is likely to occur. This has slashed average response times when something does happen. Faster clearance of accidents not only saves lives, it also prevents the massive traffic jams that tend to accumulate behind even minor incidents.

Crucially, AI systems also strive to keep the public informed in real time. Modern control centres leverage AI to automatically post accurate messages on digital highway signs and send alerts to navigation apps when trouble arises. If a major crash blocks lanes, an AI might calculate the impact on travel times and immediately suggest alternative routes, broadcasting those to drivers’ GPS units. By integrating communications, AI ensures that from emergency responders to everyday commuters, everyone gets the memo about road conditions without delay. The end goal is a road network that “thinks” and responds as a cohesive whole, spotting issues early, managing them intelligently, and guiding drivers through the situation safely.

Data-Driven Maintenance and Asset Management

Highways don’t only exist when traffic is moving; they also require round-the-clock care to fix wear and tear. The old model of road maintenance has been largely reactive, filling potholes after they form, inspecting bridges on a fixed schedule regardless of actual condition. But with sensors and AI, we’re moving toward predictive maintenance, where the road can tell us what it needs and when.

Modern smart highways are being outfitted with an array of IoT sensors that constantly measure factors like strain in bridge beams, vibration on road surfaces, temperature changes, and moisture levels. These sensors feed a continuous stream of data about infrastructure health into monitoring systems. AI and analytics can then crunch this data to detect subtle signs of deterioration. For instance, an increase in vibration signature at a bridge joint might indicate a developing crack or loose bolt. Instead of waiting for a scheduled annual inspection (or worse, a failure), maintenance crews can be dispatched proactively to address the issue. “With tools like Blyncsy and our asset analytics solutions, we can predict which parts of the road network require immediate attention, thus preventing accidents before they happen,” notes Aryal. In other words, the combination of big data and AI gives highway agencies something like a sixth sense, an ability to foresee problems and fix them in advance.

Potholes are a perfect example. They often start as small cracks that widen with water and traffic stress. AI systems using camera data or vehicle feedback can spot the early stages of pothole formation, slight depressions or cracks, and flag those locations for repair crews before a tire blows out. In fact, some cities are leveraging crowdsourced data from vehicles (even dashcam footage analysed by AI) to identify road damage rapidly. Bentley’s aforementioned Blyncsy tool is one such innovation: it collects images from dashcams and other sources to pinpoint issues like potholes, faded lane markings, or damaged signs. By anonymising the data to preserve privacy, it then delivers actionable maintenance alerts. “Imagine being able to identify areas where zebra crossings have faded or where pedestrian signs are missing, all from crowdsourced data,” Aryal explained, emphasizing that this approach finds and fixes hazards before they lead to accidents.

Pairing AI analytics with robotics is another leap forward in highway maintenance. Drones and autonomous robots can be deployed to inspect infrastructure in ways humans can’t easily do. Drones equipped with LiDAR or high-resolution cameras can scan miles of roadway or bridge surfaces for tiny defects. Machine learning models then analyse those scans to classify cracks or corrosion. In some cases, robotic devices can even carry out minor repairs, for example, filling cracks or painting over lane lines, guided by AI vision. While still emerging, these tech-driven maintenance methods promise to reduce the need for dangerous manual inspections (like hanging under a bridge) and minimise traffic disruptions by doing quick fixes autonomously during off-peak hours. We are heading toward a future where the first eyes on a problem might not be a human’s at all, but an intelligent system tirelessly patrolling the road network 24/7.

Another advantage of digital maintenance management is optimizing the big picture strategy for asset upkeep. Traditionally, roads and bridges are repaired or resurfaced on predefined cycles, say every 10 or 15 years, or when visible damage forces action. AI can help agencies move to a risk-based maintenance schedule. By continuously evaluating conditions, the AI might reveal that a certain bridge is holding up well and can go a few more years before overhaul, while another in a harsher micro-climate needs attention sooner than the standard interval. Resources can then be allocated to where they’re truly needed most, stretching maintenance budgets further and preventing unexpected failures. “You can inspect and maintain assets on a more risk-based perspective because you have a lot more insight into what happened, and what’s happening,” Aryal explains of the sensor-informed approach. Essentially, the data removes the guesswork, agencies can invest in the right fix at the right time.

All of this relies on maintaining a digital legacy of the infrastructure. When a project finishes construction, instead of handing over only paper as-builts, more owners are now receiving a digital twin of the completed asset. That twin becomes a live repository of everything to do with the road: the materials used, the exact placement of underground utilities, the maintenance history, and real-time performance data. “Being able to hand over every bit of information in context, from design through construction, would revolutionise the way people operate and maintain their assets,” Aryal emphasises. By preserving this rich data continuity, agencies ensure that nothing is lost in translation over a highway’s decades-long life. The digital twin that helped design and build the road transitions seamlessly into an as-maintained model, continually updated with inspections and sensor inputs. Down the line, if a new project or an expansion is planned, that same twin provides a head start with all historical knowledge attached.

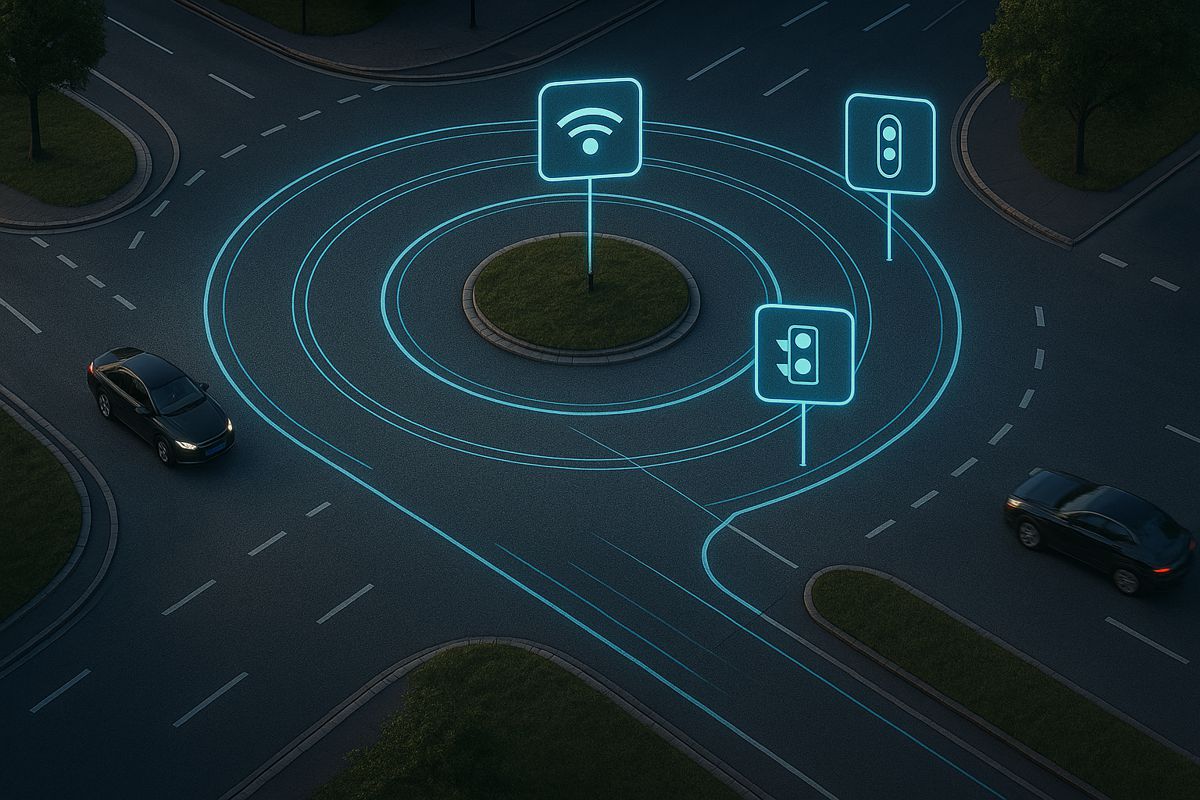

Connected Vehicles and Smart Infrastructure

No discussion of smart highways would be complete without talking about the rise of connected and autonomous vehicles (CAVs) and how roads are adapting to meet them. Tomorrow’s cars and trucks, many already on the road today, are equipped with internet connectivity, vehicle-to-vehicle communication, and advanced driver assistance or self-driving capabilities. To truly unlock their potential, the highway itself must join the conversation.

Connected vehicles use technologies known as V2X (vehicle-to-everything) communication to swap data with traffic signals, road sensors, and each other. Already, pilot programs in places like the UK, US, and Australia have installed roadside units that broadcast signal timings or road hazard information directly into vehicles. For instance, a smart traffic light can send a message to a coming car about how many seconds until it turns red, enabling the car (or its driver) to adjust speed accordingly. Conversely, vehicles can signal the network about their position and speed. A V2X-enabled highway essentially becomes an interactive digital platform, where vehicles and infrastructure jointly coordinate traffic flow.

Software and programming are the unsung heroes behind this coordination. A simple example: when an emergency vehicle is approaching an intersection, a connected system can turn lights green in its path. But to do so, the traffic control software must interpret the vehicle’s signal and execute the right commands, all in real time. These kinds of smart corridors are already being tested. In Phoenix, Arizona and in parts of Europe, connected vehicle pilots are demonstrating reduced emergency response times and smoother traffic by granting pre-emptive right-of-way based on digital requests from vehicles. Similarly, highways outfitted with C-V2X (cellular vehicle-to-everything) tech are now communicating work zone status and slow-down warnings to approaching cars, even if those cars are around a blind curve or otherwise out of sight.

Autonomous vehicles (AVs), which use AI to drive themselves, stand to gain enormously from smart highways. Self-driving cars are packed with sensors (cameras, radar, LiDAR), but they can still benefit from extra information that a roadway can provide. High-definition mapping and digital twins of highways ensure AVs have accurate knowledge of lane layouts, merges, and speed limits. Moreover, smart infrastructure can broadcast subtle information like upcoming road surface conditions (e.g. “ice on bridge ahead”) or recommend merging patterns in heavy traffic. All of this helps AVs make better decisions. As Aryal pointed out, even something as simple as well-maintained lane markings becomes critical in an AV world: “For autonomous vehicles to operate safely, they rely on accurate road markings and signage. Our technology ensures that these elements are kept up to standard.” In essence, smarter maintenance (powered by AI and digital twins) is an enabler for autonomous driving because it keeps the physical canvas of the road readable for machine vision.

We’re also seeing highways being designed with future tech in mind. Some forward-looking projects are embedding sensors and communications conduits during construction to avoid retrofits later. In China and parts of the EU, pilot “smart roads” have been built with fibre-optic cables and electromagnetic strips under the pavement, aimed at supporting ultra-precise vehicle positioning and even in-motion wireless charging of EVs down the line. While these are experimental, the concept is that the road itself will provide services to vehicles, from internet connectivity to electric power. Managing these complexities will require robust software control systems, effectively, the road gets its own operating system to handle all the smart features alongside the core duty of holding up cars.

Connected and autonomous vehicles also raise the stakes for interoperability and data handling. Highways will be pulling data from myriad sources (different car manufacturers, mapping services, city traffic systems) and pushing information out to drivers and vehicles. Ensuring everything speaks the same language is a big challenge. Stakeholders are actively working on open standards for vehicle communications and smart city data sharing. One promising approach is to use the digital twin as a central hub, a single integrated model of the road network that can interface with many systems. National Highways in the UK, for example, is investing in a unified digital model of its entire road network to serve as the backbone for these connected technologies. This “single source of truth” can host inputs from maintenance systems, traffic AI, and vehicle data, and then output coordinated insights to everyone from control room operators to the cars themselves.

Ultimately, CAVs and smart highways have a synergistic relationship: vehicles make roads smarter by providing rich data (like a crowd-sourced sensor network), and smart roads make vehicles smarter by guiding them and smoothing out the environment they operate in. Together, they promise to reduce human error (a factor in most crashes), increase road capacity by enabling tighter and more efficient traffic flows, and give travellers a smoother ride. The journey to that future is still ongoing, but every new pilot deployment and technology standard brings us a step closer to highways where the only thing “dumb” on the road is perhaps the occasional nostalgic vintage car.

Sustainability Through Technology

For all the high-tech bells and whistles, one of the most profound impacts of digitalizing our highways is a positive effect on the planet. Transportation is a major contributor to carbon emissions and energy use, and highways are on the front lines, both in terms of the vehicles they carry and the infrastructure itself. Digital tools and AI are becoming key to shrinking the environmental footprint of road networks, aligning with global goals to combat climate change and achieve net-zero emissions.

One immediate way smart highways help the environment is by reducing traffic congestion, which in turn cuts fuel waste and emissions. Idling in traffic or stop-and-go driving burns far more fuel per mile than cruising smoothly. As discussed, AI-managed traffic systems can alleviate gridlock by optimizing signal timings, ramp metering, and speed limits. Even a small improvement in average traffic flow can translate into significant fuel savings when multiplied across millions of vehicles. In Nashville’s AI traffic experiment (the CIRCLES project), smoothing the flow led to noticeable improvements in fuel efficiency and lower tailpipe emissions for everyone on the road. By preventing the “phantom jams” and unnecessary braking that plague busy highways, smart systems are effectively trimming the excess CO<sub>2</sub> that would have been emitted during all that wasted time on the road.

AI can also encourage eco-driving behaviours. In connected vehicle ecosystems, drivers (or their onboard computers) can receive real-time feedback on how to drive more efficiently, for example, suggesting a steady speed to “ride the green wave” of upcoming signals or gentle acceleration patterns to conserve fuel. Fleet operators are using AI route optimization to minimize mileage and avoid congested corridors, which not only saves fuel but also reduces local air pollution in city centres. On a policy level, data-driven insights from AI could help cities implement smarter congestion pricing or low-emission zones, by identifying exactly when and where interventions would yield the best environmental benefit. In short, digitizing traffic management is as much an eco-innovation as it is a mobility improvement.

Another sustainability angle is energy efficiency in highway operations. Running a highway involves powering thousands of street lights, message signs, toll plazas, tunnels with ventilation fans, and more. AI is being used to optimize this energy use. For instance, intelligent street lighting systems can dim lights during low traffic periods or adjust brightness in response to weather (dimming when the moon is bright, or brightening in heavy rain). Instead of crude timers that might light an empty road at 3 AM, AI makes fine-grained decisions that maintain safety while slashing electricity waste. In highway tunnels, AI control of ventilation can ensure fans run at just the necessary speed needed to clear exhaust when traffic builds up, but not run flat-out when few cars are passing through. These measures add up, some studies have shown smart lighting alone can cut energy use by 30-50% on roadways where it’s implemented.

Highways are also key enablers of the electric vehicle (EV) revolution, and technology ensures that this transition is smooth and green. AI-driven systems are managing the rollout of EV charging infrastructure along major routes. They predict where charging demand will be highest, help utilities plan for the power loads, and can even schedule charging during off-peak grid hours to use cleaner energy. On some highways, “smart charging” stations communicate with approaching EVs, guiding drivers to available chargers and optimising charge speed based on battery status. Future concepts imagine even more advanced solutions like dynamic inductive charging lanes, and while those are experimental, any such system would heavily rely on AI to orchestrate the complex timing and energy distribution required. The bottom line is that from facilitating EV adoption to lowering the power usage of infrastructure, digital tech is helping highways themselves become greener.

One must not forget the sustainability gains during construction and maintenance as well. BIM and digital twins support sustainable construction practices by enabling precise resource planning and reducing waste. If you know exactly how much steel and concrete is needed (thanks to accurate BIM quantities), you’re less likely to over-order materials that go unused. Fewer change orders and mistakes also mean less wasted material. Furthermore, BIM’s energy simulation capabilities allow designers to optimise things like lighting or drainage for long-term efficiency. For example, engineers can simulate how a new highway alignment might affect local ecosystems or how different pavement materials might mitigate heat absorption, and choose the option with a smaller environmental impact.

Overall, smart highways align with the ethos of sustainable development: doing more with less, and being smarter stewards of resources. As Nick Harris highlighted, this digital revolution in roads is an opportunity not just to improve travel but also to support net-zero climate goals. By cutting unnecessary emissions, reducing waste, and integrating clean energy solutions, the highway of the future aims to be a friend, not a foe, to the environment.

Empowering the Workforce and Future-Proofing Skills

The influx of technology in infrastructure is also transforming the human side of the industry. Building and operating smart highways requires a new blend of skills, and it’s bringing together professions that used to work quite separately. Civil engineers now collaborate with software developers, data analysts sit alongside traffic managers, and maintenance crews might work with tablets and drones as much as with shovels and wrenches. To make the most of the digital tools, investing in education and training is key.

Construction firms and transportation agencies worldwide are starting to prioritise upskilling their workforce in digital competencies. This can range from teaching BIM modeling and data analysis to project managers, to training highway technicians in using sensor diagnostics equipment. Many software providers, Bentley Systems included, offer structured training programs for their platforms. For example, a highway design team might undergo courses in 3D modeling software and learn to incorporate local design standards automatically into the BIM process. Contractors are encouraging field staff to get comfortable with project management apps and remote collaboration tools, ensuring that the technology is actually adopted on site and not just in the head office.

The industry is also forging partnerships with universities and professional organisations to keep curricula up to date. Forward-looking civil engineering programs now include modules on programming, GIS, and data science, reflecting the reality that tomorrow’s engineers will likely be programming sensors or analysing traffic algorithms in addition to calculating bridge loads. In short, the definition of an “infrastructure professional” is broadening. “By using AI to auto-generate designs and documentation, we’re freeing up engineers to tackle the complex problems that require human creativity,” Aryal said, highlighting that automation can handle routine tasks and allow people to focus on higher-level challenges. This sentiment captures how technology is seen not as a replacement, but as an augmentation of human expertise.

For smaller firms and contractors, access to technology and training can be a hurdle, but it’s one the industry is addressing through collaboration. Governments and large clients sometimes mandate the use of BIM or digital project delivery on public jobs, which in turn pushes all participants, big and small, to build capability. Industry groups and alliances (like national BIM initiatives) often provide shared resources or subsidies for training SMEs, so that no one is left behind. The goal is an ecosystem where even a modest local roadbuilder can bid on a project that uses digital processes, without being outgunned by larger rivals just because of tech know-how. Open standards and affordable cloud-based tools are making it easier for smaller players to join in, you no longer need a room of supercomputers to run a 3D model or host a collaboration platform; a basic internet connection and a tablet will do.

Another aspect of workforce empowerment is cultural change. The construction and highway sector has a reputation as traditional, but that is rapidly changing as a new generation of tech-savvy professionals enters, and veterans see the benefits of modern methods. Companies that champion innovation tend to attract talent, especially younger engineers who are eager to use the latest tech. Conversely, there’s a growing understanding that resisting digital change could mean getting left behind competitively. We’re seeing roles emerge that were unheard of years ago: drone pilot for a construction site, data scientist for a transport department, or BIM manager as a core member of a project team.

Crucially, leadership from both the private and public sectors is supporting this transition. Many government agencies are not only requiring technology use but also collaborating to set standards and share best practices. Aryal noted that Bentley works with government and industry bodies to set safety and technology standards, emphasising a collective mission: “Our mission is to ensure that infrastructure is not just functional but also safe and sustainable. By working with international standards bodies, we’re helping shape the future of transportation.” When the industry speaks with a united voice on training and standards, it accelerates adoption and gives clarity to education providers about what skills to teach.

In summary, the move to smart highways is as much about people as it is about gadgets and code. By nurturing a workforce that’s fluent in both construction and technology, the sector is future-proofing itself. The payoff will be projects delivered by teams who can seamlessly integrate new tools, continually innovate, and drive even better outcomes for safety, efficiency, and sustainability.

Paving the Way for Smarter Roads Ahead

From digital blueprints to AI-driven traffic control, the global highway industry is clearly on a one-way journey toward greater intelligence and connectivity. And this is a journey with benefits for everyone involved, drivers get safer and smoother trips, infrastructure owners get more bang for their buck through efficient operations, and communities enjoy more sustainable and responsive transport networks. The past sections have shown that this transformation is not some distant fantasy; it’s happening now, in projects and programs across the world.

One could visit a new highway project today and see drones mapping the site, engineers collaborating in VR models, sensors being embedded into fresh pavement, and AI algorithms tweaking traffic signals in the city nearby. The vision of roads as “sophisticated digital platforms” rather than mere stretches of asphalt is becoming reality. And as these technologies mature and costs come down, we’ll see them not just on flagship mega-projects but on routine road improvements and maintenance jobs in towns and cities everywhere.

Of course, challenges remain. Issues of data privacy, security, and ethical use of AI on public roads must be carefully managed to earn public trust. Agencies will need to ensure transparent algorithms and guard against biases, so an AI that controls who gets a green light must be fair and explainable. Investment will be needed to retrofit existing infrastructure with smart tech, not just build new. And stakeholders must continue working together so that all the moving parts (vehicles, infrastructure, software platforms, regulations) interoperably fit into a coherent system. These are significant tasks, but none are insurmountable, especially given the momentum we’ve already seen.

Every new success, each congestion prediction that prevents a jam, each construction simulation that averts an accident, each sensor that saves a bridge from failing, reinforces the value of the digital approach. It inspires further innovation and investment. Policymakers are increasingly crafting frameworks that mandate or incentivise digital methods in infrastructure, knowing that the returns come not only in cost savings, but in lives saved and carbon emissions avoided. And as the technology advances, even possibilities like autonomous vehicles or climate-resilient infrastructure (guided by sophisticated modeling) move from the horizon into the actionable plan.

In essence, the world’s highways are entering a renaissance of innovation. The roadbuilding sector, often seen as conservative, is now on the cutting edge of IoT, big data, and AI application. It’s an exciting time to be in construction and infrastructure, a sentiment echoed by professionals who have witnessed more change in the past few years than in decades before. There’s a growing confidence that digital tools can crack problems that used to be deemed intractable. Traffic fatalities, for instance, which claim over a million lives per year globally, are being targeted with an arsenal of smart solutions from predictive analytics to connected-car warnings. The vision of zero road deaths, while ambitious, feels a bit more attainable with these technologies in play.

As we pave this digital road to the future, success will hinge on sharing knowledge and staying adaptable. The best solutions in one part of the world can be exported to another, whether it’s a clever AI algorithm from a Silicon Valley start-up or a robust national BIM standard developed in Europe. The construction news we’ll read in coming years is likely to feature breakthroughs like roads that self-diagnose and communicate their status, construction sites that produce near-zero waste thanks to precise planning, or perhaps the first stretches of highway that can charge electric trucks on the go. These advancements may sound far-fetched today, but they are rapidly coming into view.

In conclusion, building smarter highways is a journey of continuous improvement, not a destination. The “digital life of a road” now truly spans from inception to legacy, with technology enriching every step in between. And while concrete and asphalt will always form the literal road surface, it’s the invisible digital layer, the data, models, and intelligence that will define the road’s performance in the 21st century. By embracing this change, the global infrastructure community is not only optimizing how we build and travel, but also ensuring that our roads can meet the demands of a rapidly changing world. The path forward is clear: the highways of tomorrow are being coded today, and every byte and beam working together will carry us all to a smarter, safer, and more sustainable future on the road.