Doosan Bobcat Unveils eFORCE LAB to Drive Modular Battery Innovation

Doosan Bobcat has taken a significant leap in its electrification journey with the launch of eFORCE LAB., a dedicated battery pack research and development centre in Indeokwon, Anyang, South Korea. The facility, officially opened on 26 August 2025, is set to become a pivotal hub for advancing modular, standardised battery pack technology for construction and compact equipment.

The new R&D hub reflects Doosan Bobcat’s commitment to shaping the future of energy solutions for heavy machinery. By focusing on the development of scalable, high-performance battery packs, the company is positioning itself as a key player in setting global electrification standards.

Scott Park, CEO and Vice Chairman of Doosan Bobcat, summed up the ambition behind the facility: “Electrification is an inevitable future, it’s a transformation already underway in the construction industry. With eFORCE LAB. as our global R&D hub, we’re engineering solutions optimised for the challenging environments construction equipment operates in, defining new standards in the industry.”

Pioneering modular battery technology

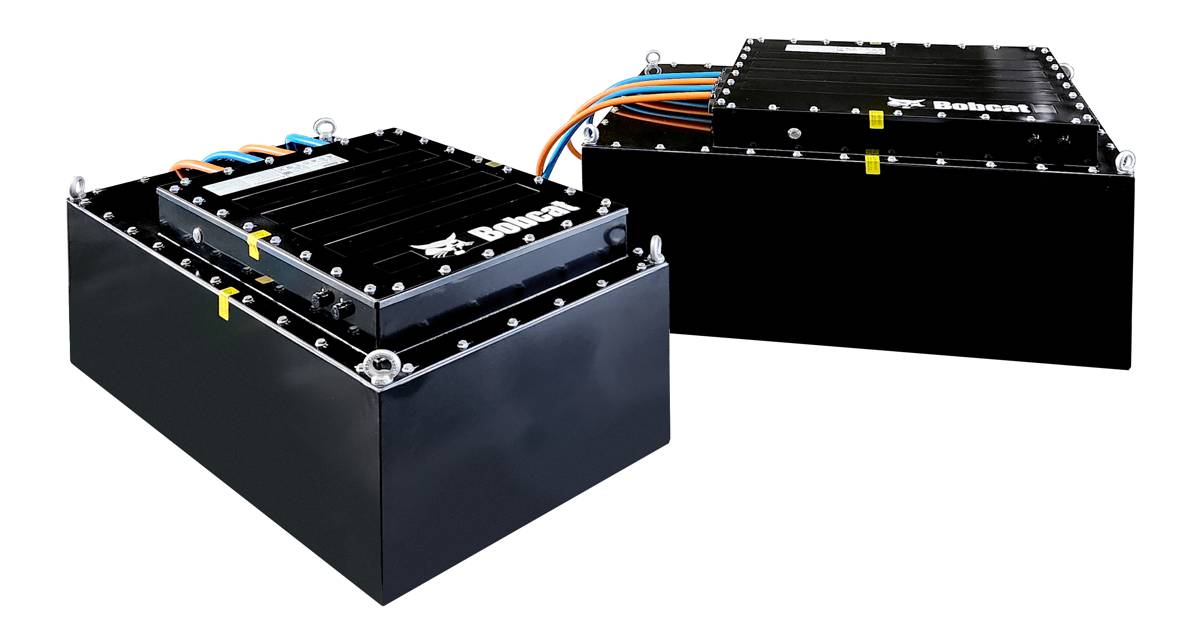

The centre’s first major project is the Bobcat Standard Unit Pack (BSUP), a next-generation modular battery system designed for construction and material-handling equipment. This innovative solution uses a building-block approach, allowing capacity to be expanded by stacking additional modules. The flexibility of BSUP is expected to accelerate adoption across multiple sectors.

Initial deployment will target Bobcat forklifts, with future rollouts planned for compact loaders, excavators, and other Doosan Bobcat products. This strategy not only increases equipment versatility but also reduces the complexity and cost of electrification for operators.

Strategic progress since 2023

Doosan Bobcat’s battery pack development began in earnest in 2023, with the successful creation of in-house Lithium Iron Phosphate (LFP) battery packs. These were commercially deployed in late 2024, powering more than 100 Bobcat forklifts. The performance of these early units has been a proof point for the company’s capability in battery engineering.

The introduction of BSUP represents a significant upgrade over earlier designs. LFP chemistry is favoured for its safety, thermal stability, and long cycle life, the attributes crucial for the demanding conditions of construction sites.

Vertical integration and supply resilience

To support this technological pivot, Doosan Bobcat has pursued a vertical integration strategy. In October 2024, the company acquired Doosan Mottrol, a specialist in hydraulic components. This move has strengthened the firm’s control over key drivetrain elements for both diesel and electric equipment.

By bringing battery and hydraulic technologies in-house, Doosan Bobcat is ensuring greater supply chain resilience, improved product quality, and the agility to innovate without relying on external suppliers.

Positioning for a changing industry landscape

The global shift towards electrification in construction equipment is gathering pace. Regulatory pressures, customer demand for sustainable solutions, and advances in battery technology are converging to reshape the industry. Modular battery packs, like the BSUP, could become the backbone of a new generation of electric machinery.

According to industry analysts, the market for electrified construction equipment is projected to grow substantially over the next decade, with modular designs playing a critical role. They offer the flexibility to match power requirements to specific applications, extend equipment runtime, and simplify maintenance.

The eFORCE LAB. initiative places Doosan Bobcat in a strong position to capitalise on these trends, creating technology that not only meets today’s needs but anticipates the demands of tomorrow’s work sites.

Engineering for harsh environments

Construction equipment operates in some of the most punishing conditions, from extreme temperatures to dusty, wet, and uneven terrains. Battery packs in this sector must endure impacts, vibrations, and long duty cycles without compromising performance.

Doosan Bobcat’s R&D focus is on engineering battery solutions that maintain consistent output under such conditions. This includes robust thermal management systems, durable enclosures, and advanced monitoring to optimise battery health over time.

A name that reflects purpose

The name eFORCE LAB. combines the “e” from electrification, energy, and eco-friendly with “Force”, symbolising the strength and innovation driving the company’s mission. This branding underscores Doosan Bobcat’s intention to lead rather than follow in the race to decarbonise heavy machinery.

The inauguration event brought together senior leadership, including Hyungwon (HW) Park, President of Doosan Bobcat ALAO, and other global executives, to outline the centre’s role in shaping future equipment design.

A forward-looking vision

With eFORCE LAB., Doosan Bobcat is not just building batteries, it’s building a framework for the future of construction equipment. The combination of modular design, in-house manufacturing, and application-specific optimisation could well set new industry benchmarks.

If successful, the BSUP and subsequent innovations will give customers greater flexibility, lower total cost of ownership, and the ability to transition to electric machinery without sacrificing capability.

Driving the next era of equipment electrification

Doosan Bobcat’s move signals a clear intent to be at the forefront of electrification in construction. As the company rolls out its modular battery systems, it will help drive industry-wide adoption of cleaner, more efficient technologies.

The eFORCE LAB. stands as both a research hub and a symbol of the company’s commitment to a sustainable future.