GPR Mapping to Unlock the Secrets of Steel Fibre Reinforced Tunnel Linings

As global cities grow denser and surface land becomes increasingly scarce, the push underground has never been more urgent. Urban tunnels today carry more than just traffic. They channel water, energy and communications infrastructure, forming the hidden backbone of modern cities. Shield tunnelling has become the go-to method for urban underground projects because it offers high efficiency and minimises risks to buildings and the surface environment.

For decades, most shield tunnel linings have relied on precast reinforced concrete (RC) segments. While dependable, RC linings face challenges in high-water-pressure environments, particularly when it comes to cracking and water ingress. Engineers have responded by turning to steel fibre reinforced concrete (SFRC), a material known for distributing stress more evenly and offering superior resistance to cracking and leakage.

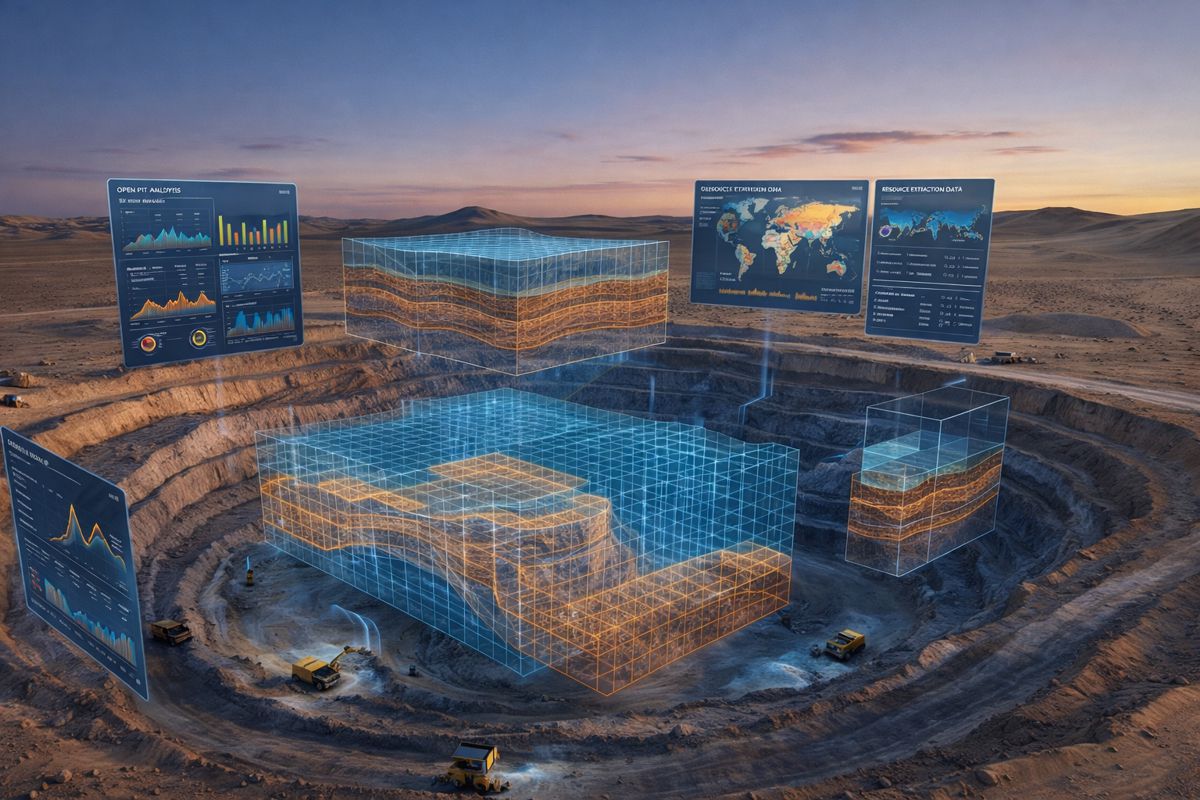

To push performance even further, many projects are now adopting multi-layer composite linings. These typically combine SFRC and RC segments with waterproof and grouting layers, giving tunnels enhanced resilience against water intrusion. But this innovation comes with a challenge: how to assess the quality of these complex linings without damaging them?

The challenge of invisible structures

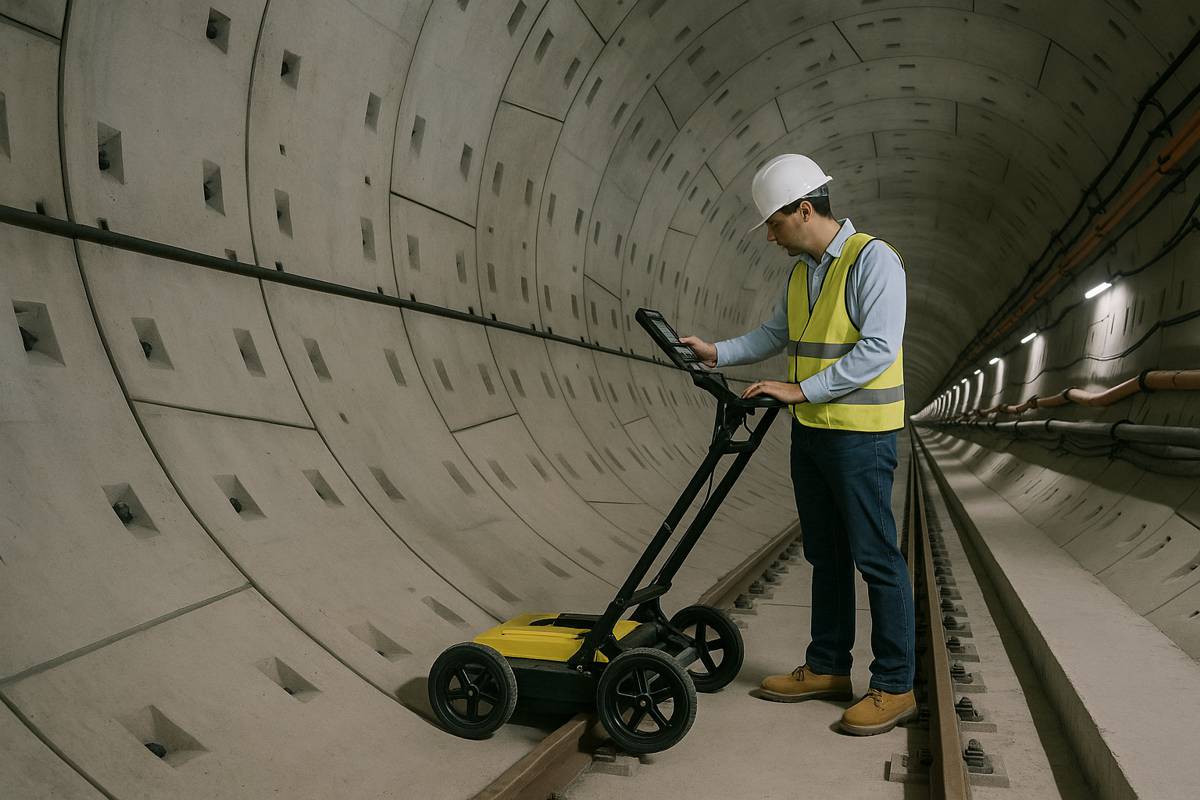

Unlike surface structures where visual checks are possible, tunnel linings are hidden behind layers of concrete and fibre. Traditional inspection methods such as core drilling or impact echo tests can reveal flaws, but at the cost of damaging the structure itself. What engineers have long needed is a reliable, non-destructive method to peer beneath the surface.

This is where ground penetrating radar (GPR) enters the picture. GPR has been used for decades in civil engineering to assess the integrity of RC linings. It works by sending electromagnetic waves into the structure and interpreting the reflected signals. But applying GPR to SFRC segments poses complications: the steel fibres scatter signals, creating noise that makes interpretation tricky. Until recently, little research had tackled this challenge head-on.

Breaking new ground in Singapore

That gap in knowledge prompted a collaboration between Tongji University, Shanghai Tunnel Engineering Co. (Singapore) Pte. Ltd., and China Railway Construction Corporation Limited. Their research, Ground Penetrating Radar Detection of Steel Fibre Reinforced Composite Linings in Shield Tunnels: Experimental and Field Studies, takes the Deep Tunnel Sewerage System-Phase 2 (DTSS-Phase 2) project in Singapore as its proving ground.

The DTSS project, one of Singapore’s most ambitious underground infrastructure schemes, involves constructing a massive network of deep tunnels to manage wastewater for decades to come. Its scale and technical demands made it the perfect setting to test how GPR could be applied to SFRC-RC composite linings.

From simulations to real-world tests

The researchers approached the challenge in three stages:

- Numerical simulations – Using gprMax software, they modelled how electromagnetic waves behave when passing through randomly distributed steel fibres in concrete. This allowed them to test different frequencies and identify which ones penetrated best.

- Model experiments – They then built physical test models that replicated actual tunnel lining conditions. By running GPR scans at varying frequencies, they studied how different signal strengths revealed material interfaces and potential defects.

- Field testing – Finally, they deployed GPR equipment inside the DTSS tunnels, gathering real-world data and comparing it with the predictions from simulations and lab experiments.

The multi-stage approach ensured that findings were not only theoretically sound but also practically validated in a real engineering environment.

The breakthrough findings

The study’s results are highly significant for the tunnelling industry. It found that GPR is indeed capable of assessing SFRC-RC composite linings effectively, provided the right frequency is chosen. The sweet spot turned out to be 300 MHz, which struck the best balance between penetration depth and resolution. At this frequency, the radar could clearly distinguish the different layers of the lining system.

Equally important, the research team developed empirical formulas based on exponential and power function fitting to describe how GPR signals attenuate as they pass through SFRC-RC linings. These formulas provide engineers with practical tools to interpret GPR data and quantify lining quality more reliably.

Wider implications for tunnel engineering

The successful application of GPR to SFRC-RC linings marks a milestone for underground engineering. It demonstrates that non-destructive testing methods can keep pace with advances in tunnel construction materials. For megacities facing rising demands for safe, watertight underground infrastructure, this is a breakthrough that could set new industry standards.

Non-destructive quality assurance is especially vital for projects where repairs are costly and disruptive. Deep sewer systems, metro networks and energy tunnels are all examples where failures are not only expensive but potentially catastrophic. Having the ability to assess linings without drilling or cutting into them represents both a cost saving and a risk reduction.

Global research context

This study builds on a growing body of international work exploring advanced non-destructive testing for underground infrastructure. While RC linings have been extensively studied, SFRC applications are relatively new, particularly in composite configurations. Similar research is emerging in Europe and Japan, where urban infrastructure demands are pushing engineers to innovate in both materials and monitoring.

For instance, studies from the European Commission’s research programmes on underground infrastructure have also highlighted the need for smarter inspection tools as composite linings become more widespread. Singapore’s DTSS-Phase 2 now stands as a case study showing how global knowledge can be applied at scale in practice.

Voices from the research

As the authors note in their paper: “The optimal frequency for detecting SFRC-RC composite linings is 300 MHz, which can clearly identify the interfaces of different layered media.” They go on to highlight that the empirical formula they developed can serve as a quantitative guide for interpreting attenuation in future projects.

Their work doesn’t just answer an academic question. It provides engineers and contractors with practical, field-tested parameters that can immediately improve quality assurance in tunnel construction.

Looking ahead: smarter underground infrastructure

The findings from Singapore point towards a future where underground infrastructure is monitored more intelligently from the start. By integrating GPR and similar technologies into routine inspection regimes, tunnel operators can extend asset life, reduce maintenance costs and enhance safety.

With cities like London, Tokyo, and New York also investing heavily in underground expansion, the ripple effect of this research could be global. It may even drive equipment manufacturers to design GPR systems specifically optimised for SFRC detection, opening a new market in construction technology.

Building confidence underground

The ability to see the unseen has always been the engineer’s challenge. This research demonstrates that with the right tools and careful calibration, even complex materials like steel fibre composites can be assessed non-destructively.

For policymakers, contractors and investors, it signals greater confidence in the durability of tomorrow’s underground networks.