Buying Roof Guardrail Systems – Where to Start and What to Know

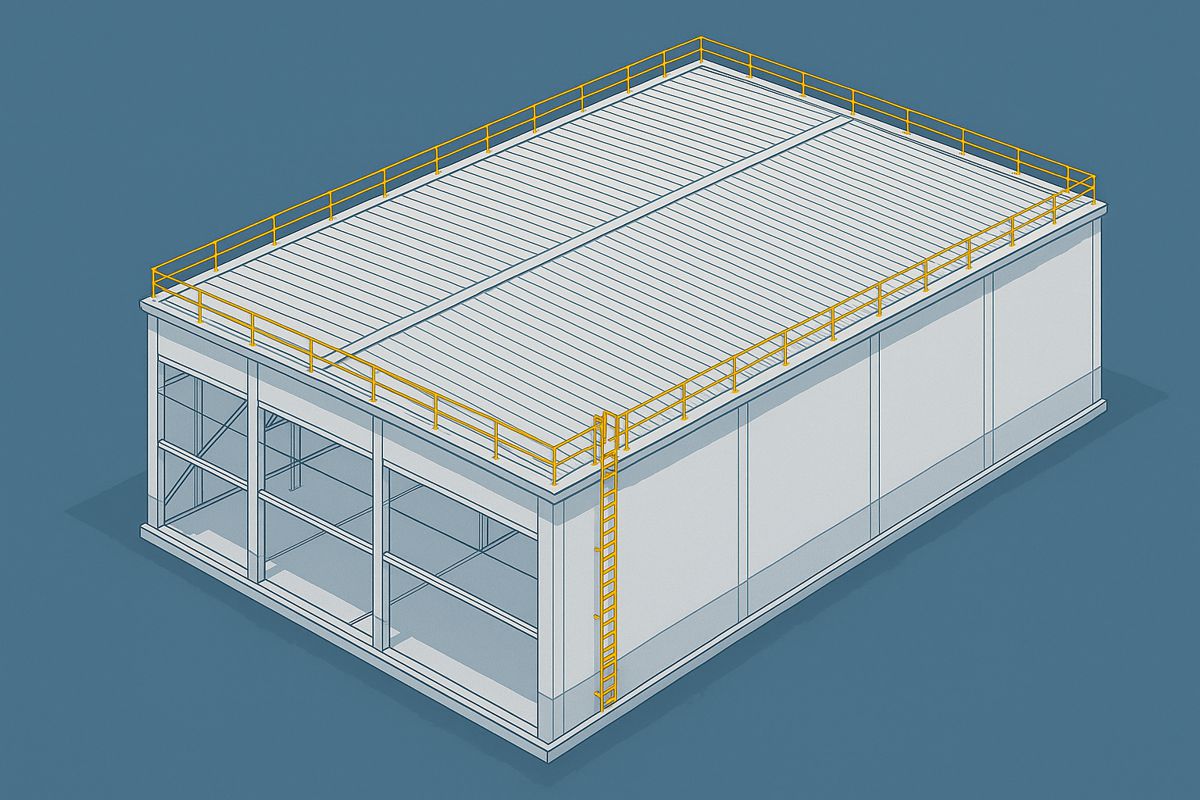

Roof guardrail systems are essential for preventing falls at construction sites, addressing one of the major safety hazards associated with work at heights. Effective systems establish secure perimeters that protect workers and ensure compliance with safety regulations.

Contractors and site managers must understand the types, materials and applications of systems to ensure safety, durability and long-term value in installations.

Product Overview and Safety Standards

Roof guardrail systems fall into several categories, each serving specific functions. Manufacturers design permanent guardrails for long-term use in commercial and industrial buildings, valuing them for their durability and ability to withstand harsh conditions. Project managers often choose them for large-scale projects that focus on continuous safety and reliability.

Yet, temporary guardrail systems meet the need for flexibility and mobility during short-term projects or maintenance tasks. These systems are easy to install and remove, making them practical when permanent structures are not workable.

Parapet-mounted guardrails offer aesthetic protection in urban and mixed-use buildings without compromising the design. Nonpenetrating systems safeguard roof membranes, avoiding the need for drilling, which is beneficial for green roofs and helps maintain waterproofing. This approach preserves roof warranties while ensuring safety standards are met.

In the United States, OSHA Standard 1926.502 requires employers to provide fall protection for any work performed above 6 feet in height. Guardrails should be approximately 43 inches tall, with a tolerance of 3 inches. Mid-rails should be placed halfway up the guardrail, and toe boards should be a minimum of 3.5 inches in height.

Additionally, the structure must withstand a force of 890 N at the top rail and 666 N on intermediate rails, ensuring the system resists vertical and horizontal loads. Compliance with these standards ensures systems perform reliably under real-world conditions, protecting workers even during high-impact events.

Where Roof Guardrails Make the Biggest Difference

Roof guardrail systems are used across commercial, industrial and residential sectors. In commercial buildings, they secure rooftops, balconies and mechanical platforms. Demand grows as more office towers, hotels and shopping centers incorporate accessible roofs into their designs.

The industrial sector depends on durable systems to handle the mechanical stress experienced by maintenance workers on complex structures. In residential applications, particularly high-rise buildings, safety for both residents and maintenance crews is paramount. As urban construction grows, developers implement permanent or parapet-mounted systems to comply with modern building codes and enhance safety.

Each application presents distinct challenges, from adapting to irregular roof shapes to integrating design-friendly materials. Manufacturers continue to innovate, combining aesthetic integration with structural strength to meet these needs.

What Defines a Great Roof Guardrail System

Material selection defines performance, longevity and maintenance costs. Steel remains the dominant choice for permanent installations, known for its strength and corrosion resistance when galvanized. Aluminum offers a lightweight alternative for projects with limited load capacity. Its natural resistance to corrosion makes it suitable for coastal environments where salt exposure can compromise other materials.

Composites and reinforced plastics provide nonconductive and chemically resistant options. These materials are well-suited for use in environments with high electrical activity or chemical exposure. Manufacturers now combine these materials with advanced coatings and modular engineering to improve adaptability and simplify installation. The result is a new generation of roof guardrail systems that blend safety, durability and ease of maintenance.

The Best Companies to Buy Roof Guardrail Systems

The following companies are great places to start when you need to buy a roof guardrail system. They combine design innovation, safety compliance, and reliability.

1. Kattsafe

Kattsafe leads the global market in height safety and fall protection systems. The company designs and manufactures advanced rooftop safety solutions that simplify compliance without sacrificing performance. Kattsafe roof guardrail systems ensure safe pathways for workers on rooftop perimeters, eliminating the need for personal protective equipment and extensive training.

The team builds each roof guardrail system to provide long-term reliability and withstand environmental stress, reducing maintenance while ensuring security. Kattsafe’s designs integrate seamlessly with existing infrastructure and meet all OSHA standards.

Key Features:

- Modular configurations fit nonpenetrating and surface-mount roofs

- Lightweight aluminum resists corrosion and needs little maintenance

- Tool-free installation reduces labor time and eliminates the need for on-site welding

2. Flexible Lifeline Systems

Founded in 1996, Flexible Lifeline Systems has become a pioneer in engineered fall protection, known for its precision and reliability in complex projects. The Rooftop Walkway with Guardrail combines slip-resistant surfaces with guardrail barriers, ensuring worker safety without the need for harnesses.

Flexible Lifeline Systems systems are modular, compliant and corrosion-resistant, making them ideal for a diverse range of roof types. The engineering team, certified in 33 states, brings unmatched technical expertise to every project. The company’s ISO 9001:2015 certification underscores its commitment to quality.

Key Features:

- Modular design and corrosion-resistant materials suit diverse roof types.

- Grade 316 stainless steel ensures lasting strength in harsh conditions.

- Adjustable uprights stay stable on uneven or sloped surfaces

3. Diversified Fall Protection

With decades of experience, Diversified Fall Protection designs, fabricates and installs complete fall protection systems tailored for every work environment. Diversified offers a full range of guardrail options, including modular, nonpenetrating and mounted systems.

The company integrates OSHA-compliant solutions that protect workers while simplifying compliance. Its national reach and local presence allow it to provide personalized service backed by deep industry knowledge. Diversified’s acquisitions, such as Rooftop Anchor and Versatile Systems, expanded its expertise.

Key Features:

- Custom layouts and modular parts adapt to different roof designs

- Freestanding bases protect membranes without drilling or anchors

- Collective protection removes the need for harnesses or lanyards

Raising the Bar on Rooftop Safety

Roof guardrail systems are a cornerstone of modern safety infrastructure, protecting workers while meeting strict regulatory standards.

Industry leaders such as Kattsafe, Flexible Lifeline Systems and Diversified Fall Protection deliver designs that blend innovation, compliance and ease of use. Their products safeguard worksites and simplify installation and maintenance to help businesses uphold safety without compromise.