Liquid-Metal Circuit Boards Pave the Way for a Recyclable Tech Future

Electronic waste has become one of the fastest‑growing waste streams on the planet, and the figures paint a grim picture. Global volumes already exceed 50 million tonnes per year, with forecasts suggesting a staggering 60 million tonnes of e‑waste annually by 2030 if no systemic changes are made. Much of this material, from smartphones to wearables and high‑performance computing hardware, ends up improperly dismantled, exposing workers and fragile ecosystems to hazardous substances like lead and mercury.

Recovering precious metals and specialised components from discarded electronics is notoriously difficult, expensive and often uneconomical. As a result, recycling rates lag far behind production growth. Amid this challenge, a team at the University of Washington (UW) has stepped forward with an inventive solution that could rewrite the rulebook on how electronics are designed, used and recycled.

“We created a lot of functionality within one material,” explained senior author Mohammad Malakooti, an assistant professor of mechanical engineering at UW. “Our goal is to build a widely useful platform for flexible, reusable devices.”

A Breakthrough in Recyclable Circuit Technology

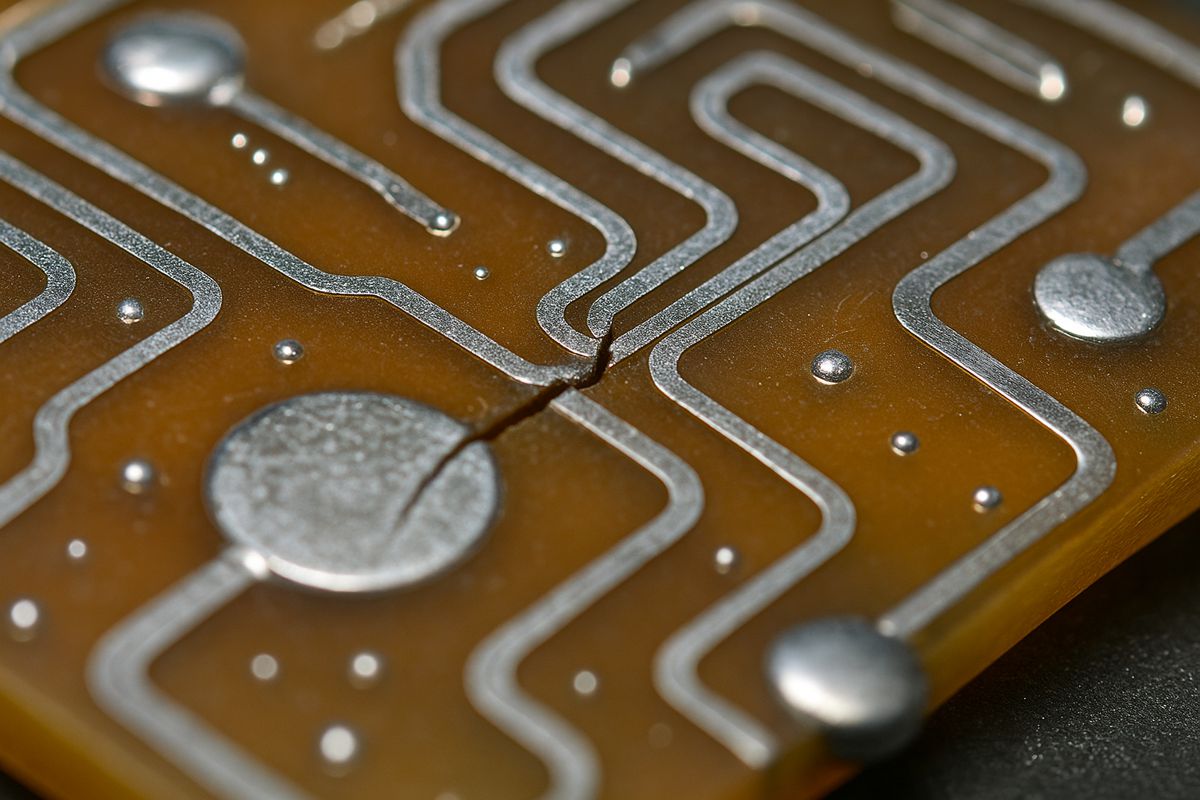

The UW team’s research, recently published in Advanced Functional Materials, introduces a flexible, self‑healing and easily recyclable circuit‑board alternative that may ultimately offer a sustainable substitute for conventional printed circuit boards (PCBs). Traditional PCBs rely on rigid fibreglass and resin substrates paired with copper traces. In contrast, this pioneering material blends a recyclable polymer with microscopic droplets of gallium‑based liquid metal alloy.

Rather than printing copper circuitry, users can simply score customised pathways into the surface of the composite, linking adjacent liquid‑metal droplets and enabling electrical conductivity. Areas that remain untouched stay insulating. This patterning approach reduces manufacturing complexity while delivering durable, flexible circuitry ideal for next‑generation smart fabrics, soft robotics and wearable devices.

Malakooti’s lab has been exploring liquid‑metal composites since 2019, using machine learning to optimise material formulations. However, rising gallium costs encouraged a pivot toward sustainability and reusability. The result is a composite that offers both recyclability and longevity.

Self‑Healing and Highly Recoverable

One of the material’s standout features is its ability to self‑heal. Users can cut the composite into sections, then rejoin and realign fragments using simple heat and pressure. Crucially, circuits continue to function even after reconfiguration, supporting iterative prototyping and extending product lifespans.

Beyond resilience, the material excels in recoverability. The polymer matrix dissolves through a chemical treatment, enabling extraction of the embedded metal droplets. In laboratory tests, the UW team reclaimed approximately 94 percent of the alloy from sample composites, offering a pathway toward economically viable recycling.

This capability aligns with emerging circular‑economy models, which emphasise designing technology to be reconfigured, repaired and ultimately reprocessed rather than discarded.

“We’re trying to make a difference now to shape the future of flexible and wearable electronics,” Malakooti noted. “We can’t make all these devices and then go back and try to figure out how to recycle them. That’s how we ended up with the electronic waste problem we face today. I want to tackle this problem from the very start.”

From Wearables to Robotics:

The potential applications for this technology stretch far beyond research labs. Soft robotics, flexible medical sensors, smart textiles, autonomous wearables and custom human‑machine interfaces all stand to benefit. As global demand grows for intuitive, ergonomic and adaptable systems, materials that combine electrical reliability with flexibility will become essential.

Recent market studies forecast that the wearable‑tech and soft‑robotics sectors will continue expanding rapidly over the next decade. Adoption of flexible circuits, sensor‑laden fabrics and adaptive prosthetics will require materials capable of conforming to complex shapes without losing functionality. The UW composite provides a promising answer, positioning itself at the intersection of performance and sustainability.

Industry leaders are actively seeking alternatives to traditional PCB manufacturing, which consumes significant energy and uses chemicals that can be harmful if not disposed of responsibly. Meanwhile, governments are tightening e‑waste legislation worldwide, from the EU’s Waste Electrical and Electronic Equipment (WEEE) Directive to evolving US state‑level recycling frameworks and Asia‑Pacific zero‑waste initiatives.

A Research Effort with Global Backing

The project was supported by the US National Science Foundation and the Department of Energy, highlighting the strategic importance of sustainable tech supply chains. Collaborators included UW doctoral researcher Youngshang Han, undergraduate researcher Shreya Paul, and Oak Ridge National Laboratory scientists Sargun Singh Rohewal, Sumit Gupta and Christopher C. Bowland.

By merging materials science with machine learning and circular‑economy principles, the team is setting a benchmark for how future electronics could be conceived. Their work aligns with rising investment in greener semiconductor manufacturing, recyclable battery systems and biodegradable electronics.

Making Electronics Fit for a Sustainable Future

With resource security and ethical manufacturing increasingly at the forefront of global policy discussions, innovations like this one are arriving at a pivotal moment. As digital transformation accelerates, demand for sensors, processors and interconnected devices will soar. A greener generation of smart devices must follow.

Looking ahead, Malakooti and his team foresee consumer products built to be re‑configured, not replaced, and components designed for disassembly and reuse rather than landfill. With the right industrial partnerships and continued research, the technology could underpin a significant shift toward sustainable electronics manufacturing.

A Greener Tech Landscape on the Horizon

While scaling remains a challenge, this development marks a major step in tackling e‑waste at its source. Instead of trying to retrofit recycling systems to fit throwaway tech, innovators are rethinking electronic materials from the ground up.

As global economies push for circular manufacturing and environmentally responsible digital systems, flexible liquid‑metal circuit composites could play a vital role in shaping a cleaner electronic future.