Smarter Matrix Storage Supercharges Finite Element Analysis Performance

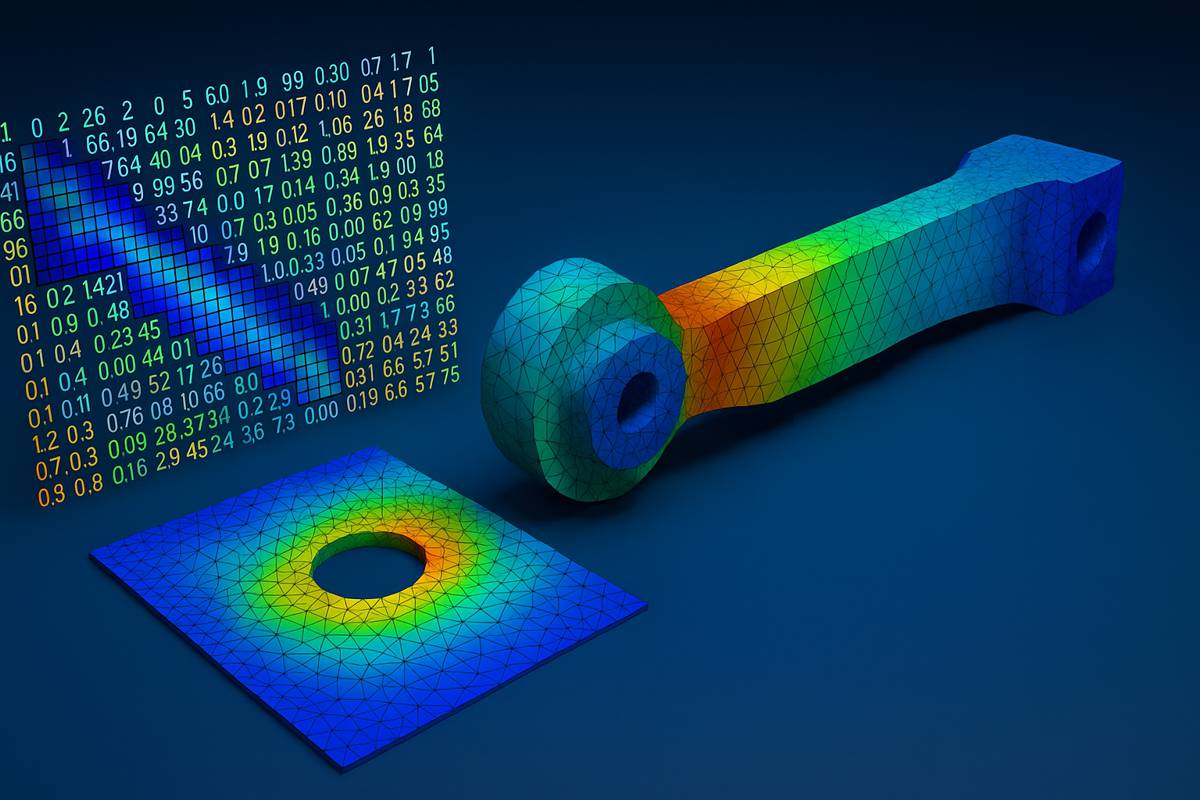

Finite Element Analysis, or FEA as it is known across aerospace, automotive, and civil engineering, has become indispensable for predicting real-world behaviour across advanced structures. With models growing ever larger and more intricate, engineers are constantly asking how to solve equations faster, store matrices more intelligently, and eliminate waste in massive computational workflows.

Although adaptive mesh refinement, assembly free techniques, and sparse matrix compression formats like CSR and CSC have all moved the dial, each approach has drawbacks. Adaptive meshing saves time yet often introduces accuracy trade offs. Assembly free methods reduce memory but at the steep cost of repeated element matrix calculations. Classic sparse matrix formats fail to capitalise on the natural block symmetry in stiffness matrices, and that leaves money on the table in both storage and computational throughput.

As industries increasingly simulate millions of degrees of freedom, pressure has mounted for a smarter approach. That very challenge has been tackled by researchers at the National Engineering Research Center of Novel Equipment for Polymer Processing and the Shien Ming Wu School of Intelligent Engineering at South China University of Technology.

Their newly proposed Blocked Symmetric Compressed Sparse Column method, known as BSCSC, embraces the inherent block symmetry of global stiffness matrices rather than ignoring it. In simple terms, the method blocks the matrix into structured regions and stores only the necessary triangle of values, significantly minimising memory and accelerating computation.

Instead of changing numerical values or approximating solutions, the team has designed an indexing innovation. That means accuracy remains untouched while efficiency climbs dramatically.

The research team explained the philosophy behind the work: The BSCSC method aims to utilise the blocked symmetric structure of the global stiffness matrix to reduce redundant storage and improve the efficiency of FEA computations.

BSCSC divides the global matrix into diagonal and non diagonal blocks, storing only one triangular portion along with minimal indexing metadata. Two vector sets handle diagonal and off diagonal blocks independently, maintaining accuracy and eliminating duplicate entries.

For 2D structural problems, the matrix splits into four blocks. For 3D applications, it expands to nine, smoothly reflecting geometric complexity.

To summarise, the methodology provides three key benefits:

- Reduces memory by storing one side of symmetric blocks

- Retains exact numerical values, protecting accuracy

- Accelerates matrix vector multiplication performance

While theory can excite academics, industry wants numbers. The research team delivered. Numerical tests illustrate just how transformative the BSCSC approach can be.

In a benchmark test featuring 20,000 four node elements, generating a 40,602 square stiffness matrix, results were emphatic:

- Memory reduced by 59.95 percent

- Total solution time cut by 62.58 percent

- Average iteration time reduced by 44.98 percent

A near 60 percent drop in resource use, without correctness compromise, signals a strong argument for industrial adoption.

Scaling up the problem to 16,384 eight node hexahedral elements and a 57,915 square matrix brought even more dramatic benefits:

- Memory reduced by 66.13 percent

- Total solution time down 72.06 percent

- Average iteration time trimmed 57.75 percent

These figures are not marginal gains. They mark a structural change in computational efficiency.

To demonstrate real industrial relevance, the researchers applied the method to a complex engine connecting rod model with 79,005 elements and more than 50,000 degrees of freedom. Once again, results impressed:

- Memory consumption lowered by 65.85 percent

- Solution time reduced by 68.65 percent

That level of performance in a geometry loaded with stress gradients, varying thicknesses and contact challenges underscores the practical capabilities of the BSCSC format.

Traditional FEA workflows face bottlenecks from ever increasing model sizes, mesh refinement demands, and high fidelity simulation requirements driven by electrification, sustainability goals and smart infrastructure projects. Faster solvers and lighter memory footprints directly translate into:

- Lower operating costs for engineering firms

- Ability to run larger, more realistic simulations

- Reduced cloud compute bills for software providers

- Faster design iteration cycles in aerospace, automotive and civil projects

Industry has raced toward digital twins, generative engineering and AI assisted design. All depend on efficient solvers and matrix engines. As one simulation expert at Siemens Digital Industries Software noted in related research: “When simulation performance improves, every phase of the engineering process accelerates, from concept to certification.”

Academic groups globally are investigating FEA optimisation strategies, including multigrid methods, GPU accelerated solvers and hybrid mesh free frameworks. While these innovations push performance boundaries, most require algorithmic changes, solver modifications, or precision compromises.

That is where BSCSC stands apart. The method improves indexing without altering mathematical formulations or requiring specialised solvers. Engineers can integrate it into standard workflows with minimal code disruption.

Recent publications from institutions such as MIT, ETH Zurich and Tsinghua University have echoed the need for matrix level improvements to match advancements in hardware acceleration. The BSCSC approach feeds directly into that narrative.

The research holds strong promise beyond polymer processing and mechanical structures.

Its relevance spans:

- Seismic analysis in civil engineering

- Crash simulation and fatigue modelling in automotive

- Aeroelastic and structural optimisation in aviation

- Offshore wind platform simulation and marine engineering

- Smart materials and composite manufacturing design

As FEA packages increasingly integrate AI driven adaptive meshing and physics informed machine learning, efficient matrix formats will reinforce and amplify those capabilities.

The authors observed: “The proposed method does not change the numerical values of the global stiffness matrix, ensuring computational accuracy while reducing memory and calculation time.”

Breakthroughs like BSCSC rarely arrive without momentum behind them. With continued refinement, integration into commercial FEA solvers and partnerships with CAE software developers, the approach could become a mainstream matrix standard.

As the engineering world strives for greener, smarter, faster digital performance, innovations like this enable organisations to run more simulations with fewer resources, shortening design cycles and strengthening innovation across industries.