Why the ‘Edge’ will Define Your Construction Business in 2026

When I think about 2026, I take a step back and ask where we’re investing and focusing the organization. Three themes keep coming up, and they’re tightly connected: the “edge”; the accelerating pace of AI and the platforms that make it usable; and the transformation at the “front” of construction.

By the “front,” I mean where fleets are managed, maintained, and made safer and more productive. Think of it as a simple stack: get the edge right, use AI through an open, interoperable platform, and you revolutionize day-to-day execution. Miss the foundation and the technology stack wobbles.

In construction, the edge is the machine, the controller, the on-tool electronics, the access control hardware at the site gate, and the operator’s device in the field. It is everything happening down at the machine level: component OEMs, firmware updates, compliance requirements, installation practices for data quality, and getting the data out in a way that can be interpreted.

Why does this matter in 2026? Because we are living in an era where data is the foundation for everything. While many still think telematics is just a dot on a map, it‘s not the case. Telematics and jobsite data are the raw material for safety analytics, predictive maintenance, utilization improvement, emissions reporting, and ultimately AI. If you don’t get this step right, you lose out. You can’t buy your way into historical data.

Getting the edge right is technical and often complex. Access management across multiple vendors is hard. Connectivity indoors is hard. Getting consistent controller signals across mixed fleets is hard. APIs and ISO feeds are improving, but data will not always be uniform.

That is why construction technology leaders must go deeper, into the machine, to make sure data quality, controls, and connectivity are engineered in, not bolted on later.

The human context matters as well. The edge reaches operators, service technicians, OEM engineers, and fleet managers. What can each do in the moment because the right data and controls are available at the edge? That is where productivity gains happen. A technician avoids a site visit thanks to a remote firmware update. An operator gets instant access approval. A rental branch improves indoor signal strength through better installation.

The message is simple: invest in the edge like your strategy depends on it, because it does. Validate component choices with your OEMs, document installation standards, harden connectivity for indoor and dense urban sites, and design access management that spans multiple vendors. Get this foundation right, and everything else becomes easier.

Recent research confirms this trajectory. Edge computing in construction “allows heavy machinery and construction assets to operate more intelligently, autonomously, and efficiently” by processing data locally and reducing latency, according to World Construction Today.

The second trend is the speed and scope of AI, a drum we have banged more than once before. We have a strong conviction that AI will double productivity for professional workers who sit in front of a computer. This isn’t theoretical. We have already seen nearly 20% productivity gains in engineering this year. But AI only works if the data underneath it is trustworthy, timely, and accessible. That is why the edge matters so much.

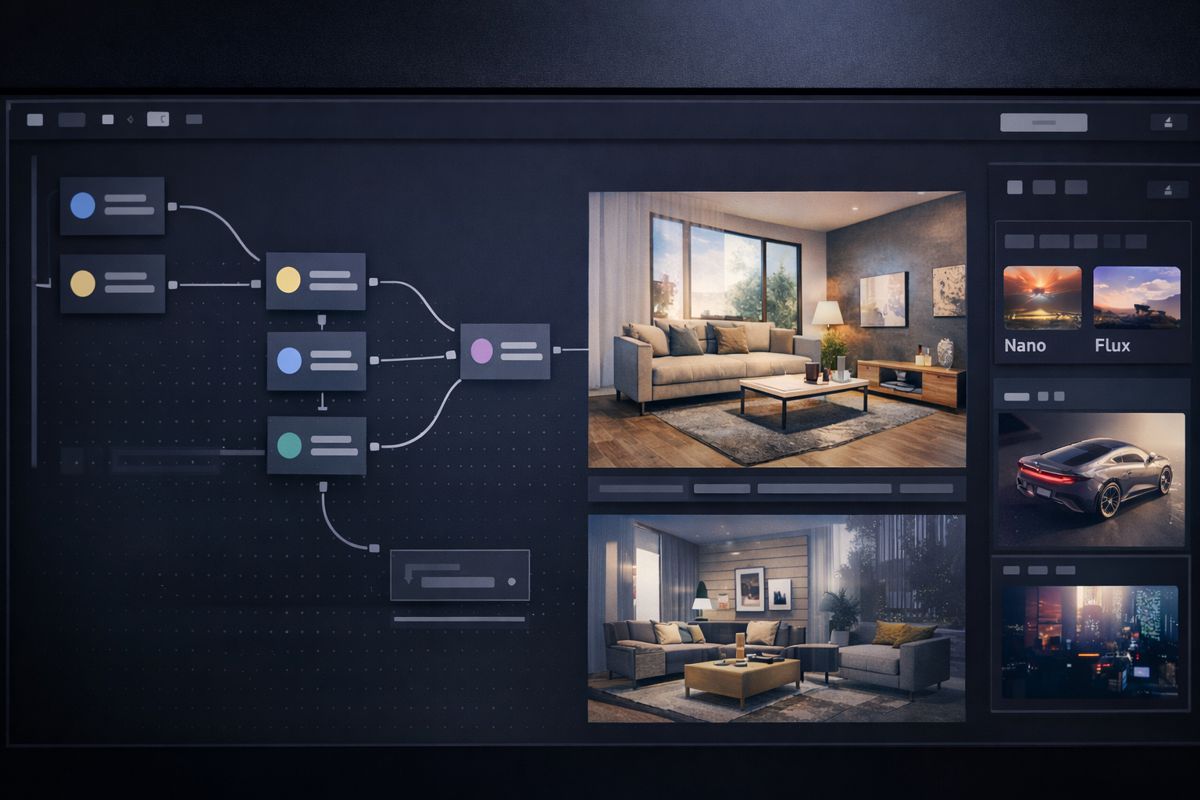

AI’s impact arrives through platforms such as industry cloud platforms or operating data platforms like Trackunit’s IrisX that integrate with the edge. Think of them as orchestration layers for your data, normalizing signals from heterogeneous fleets, aligning permissions, and producing clean datasets that AI can learn from and act on.

When done right, AI becomes easier to deploy and scale. Downtime shrinks as anomalies are flagged earlier and resolved faster. Jobsites get safer as behavior and condition patterns are recognized in real time. Sustainability reporting becomes credible and automated because fuel burn, run-hours, idling, and power choices are visible and comparable. Utilization rises because insights are embedded in workflows that dispatch people and equipment.

Keeping the platform open and transparent is essential. The AI landscape is evolving rapidly, and no single model will dominate every use case. That is why we have leaned into openness, avoiding customer lock-in. Our Model Context Protocol (MCP) lets customers use external language models and AI technologies while keeping their data governed and options open. Choose the best model for the job without having to replace your stack.

A practical framing for 2026 is this: apply AI where the data is richest and business impact is highest. Start with cross-fleet insights such as safety, utilization, maintenance, and carbon. Then move into specific use cases like anomaly detection, parts forecasting, and automated work orders. Each step is easier when the edge is strong and the platform open.

Remember that AI thrives on feedback loops. The edge creates them: what was predicted, what actually happened, how the controller responded, and whether the technician’s intervention worked. Close these loops and the AI you deploy in January will be smarter by June and far smarter by December 2026.

Analysts project that construction AI market will grow from $4.86 billion in 2025 to $22.68 billion by 2032, a compound annual growth rate of nearly 25%, reports Fortune Business. The opportunity is vast, but execution is everything.

The third trend is what all this unlocks at the front of construction, where fleet management, operations, and commercial decisions actually happen. If the edge provides reliable machine truth and your platform converts it into clean, governed data, then fleet management stops being reactive and becomes a strategic advantage.

Fleet management done right in 2026 looks like this:

- Predictive by default: Predictive maintenance moves from pilot to practice. You won’t chase alarms. You’ll act on prioritized recommendations tied to parts availability, service capacity, and schedules, cutting breakdowns and overtime.

- Access that just works: Identity and permissions span OEMs and sites. The right person gets the right machine at the right time, with fewer incidents, faster starts, and tighter controls on misuse.

- Utilization with context: Utilization stops being a single number and becomes a set of data-driven decisions. Redeploy equipment, cut idle time, or shift from diesel to electric. With edge data normalized in the platform, these choices are made inside the same workflows that plan tomorrow’s tasks.

- Safer jobsites measured: Leading indicators such as near misses, overloads, geofence breaches, and operator fatigue become visible to contractors. AI detects weak signals earlier and managers act sooner. Safety turns into a live metric.

- Sustainability that’s auditable: Emissions and energy use become part of everyday reporting. Because data quality is anchored at the edge, sustainability claims are verifiable. Fewer truck rolls, smarter charging, right-sized fleets, and reduced idle time all add up to measurable impact.

The goal is not more dashboards. It is smarter decisions where the work happens: the service screen that suggests the next best action, the dispatcher’s plan that balances utilization, and the access system that quietly enforces safety and skills. You will know it is working when people talk less about “the system” and more about the jobs finished sooner, the incidents avoided, and the nights they did not spend waiting for a part AI ordered in advance.

If you want a durable strategy for the next 12 to 24 months, you’ll see that the companies seeing results with AI are those whose data and strategy are structured towards a certain use case or a problem to be solved. In other words, it’s time to move beyond proofs of concept and reframe the conversation to building business impact cases, focused, measurable applications that connect technology investment directly to value creation.

That said, optimism is not a plan. The companies that win in 2026 will be the ones that take the edge seriously, treat AI as a capability rather than a buzzword, and manage fleets with clarity and intent.

Article by Soeren Brogaard, CEO, Trackunit