Cool Textiles For A Hotter World

Rising temperatures and longer heatwaves have pushed scientists to rethink how clothing can protect people in harsh environments. A collaborative project between the University of South Australia and Zhengzhou University has delivered a breakthrough material that reflects the sun’s energy, sheds heat quickly and keeps moisture away from the skin.

The research, detailed in the journal Nano Research, introduces a lightweight composite textile that reflects 96 percent of solar radiation. In outdoor field tests, the fabric lowered skin temperature by 2 degrees celsius in full sunlight and by 3.8 degrees celsius at night. Those reductions may appear modest at first glance, yet they make a significant difference for workers and communities living with escalating heat stress.

Addressing Rising Heat Stress

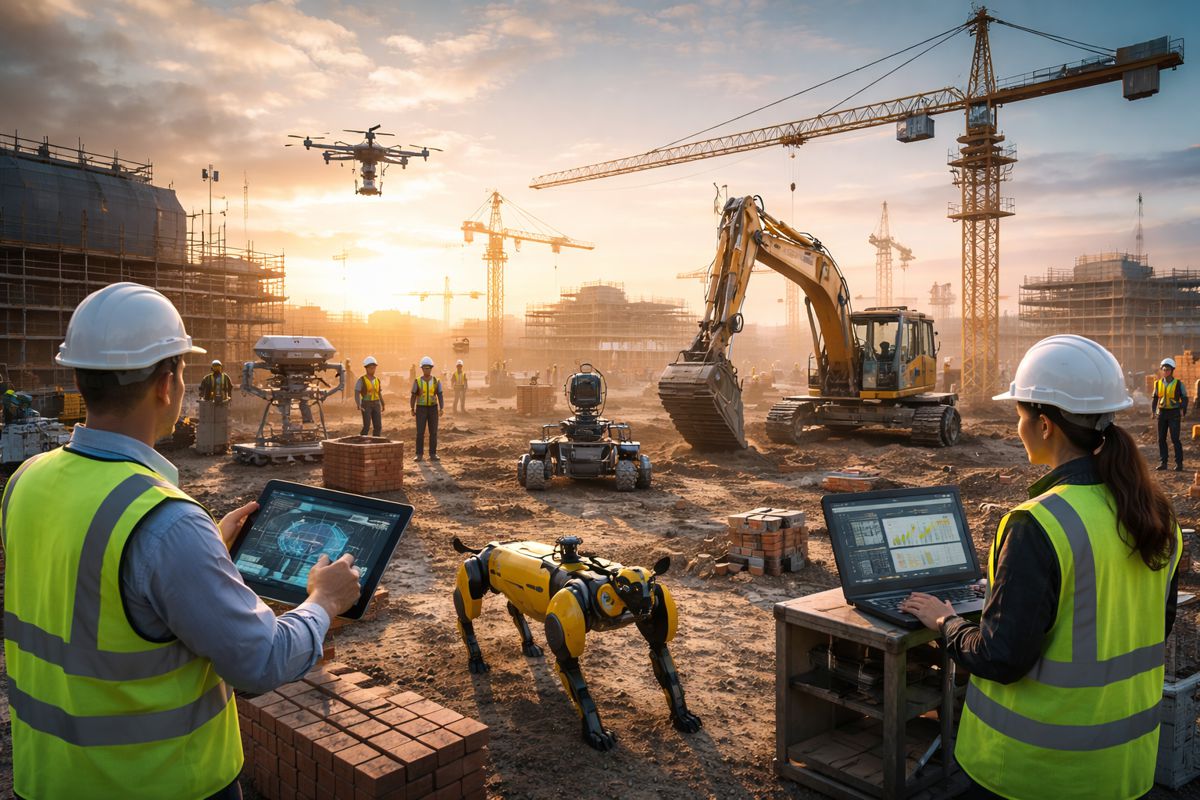

Professor Jun Ma from UniSA’s Future Industries Institute says the work responds directly to a growing global problem. “We’re seeing more frequent and intense heatwaves globally, and that has serious implications for outdoor workers, athletes and people living without access to air conditioning,” Prof Ma says. The fabric’s role goes far beyond comfort, touching on health, safety and productivity.

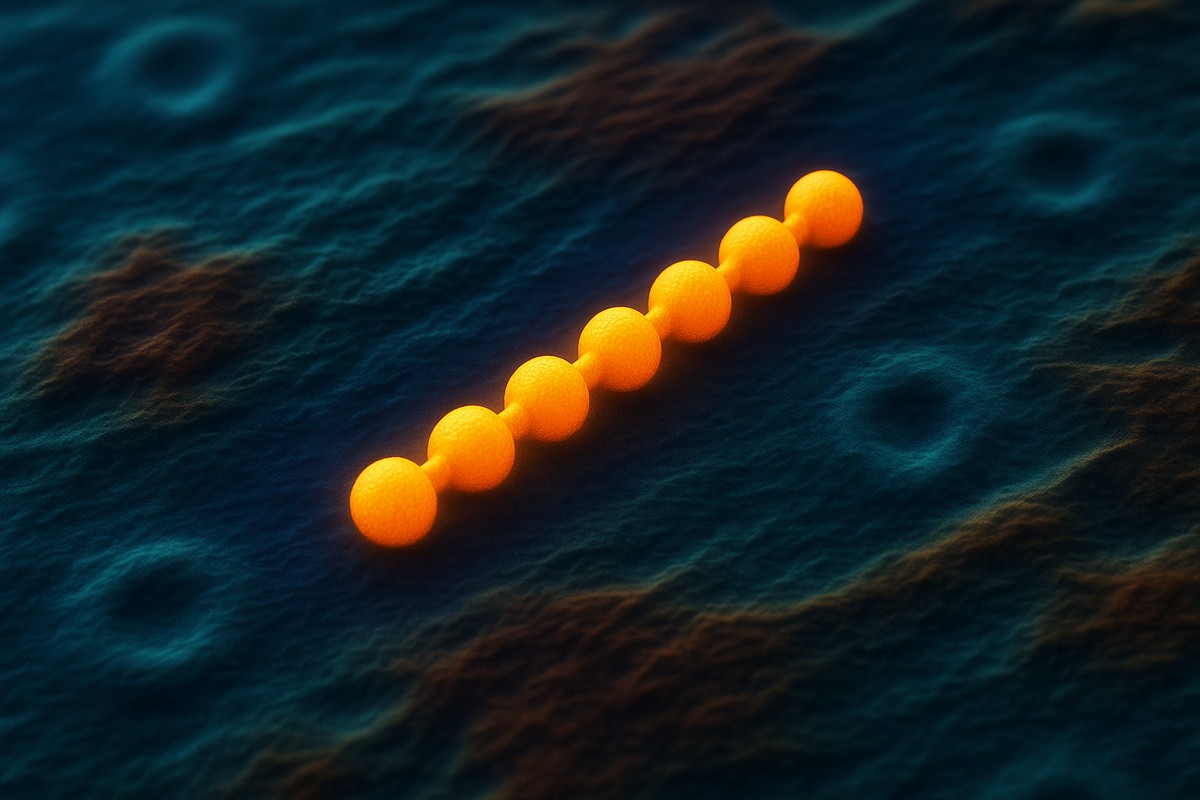

Polylactic acid and boron nitride nanosheets form the backbone of the material. Unlike cotton, which tends to trap sweat and warm air, this composite is engineered to release heat naturally. The design takes advantage of radiative cooling, a passive process in which thermal energy is emitted into the atmosphere without the need for power.

Prof Ma explains the project’s foundation: “Our goal was to design a smart, sustainable fabric that passively regulates body temperature – not by using energy, but by harnessing natural physical processes.” That principle underpins efforts across construction, mining, agriculture and emergency services, where workers face long hours under punishing conditions.

Engineering A Smarter Fabric

The team used a scalable electrospinning method to embed boron nitride nanosheets within a biodegradable fibre matrix. Electrospinning produces fine, uniform fibres, creating a nanostructured textile with excellent breathability. Early tests show that the material is five times more breathable than cotton.

Prof Ma highlights the combined effect of these properties: “The combination of high solar reflectance, heat radiation and moisture control means that the wearer feels noticeably cooler and drier.” The textile’s bright white appearance helps reflect sunlight, while its nanoscale structure enhances cooling performance.

The collaboration played a significant role in refining the material’s performance. Associate Professor Yamin Pan of Zhengzhou University emphasises the value of shared expertise: “UniSA’s advanced materials expertise helped us evaluate the heat transfer and radiative cooling properties of the fabric.” She adds that the partnership demonstrates how cross-border collaboration accelerates innovation in sustainable materials.

Environmental Responsibility And Material Choices

With polylactic acid at its core, the textile aligns with the growing shift towards renewable and biodegradable materials. PLA is sourced from natural feedstocks and breaks down more readily than many petroleum-based polymers. This supports broader industry goals aimed at reducing environmental impacts across textiles, workwear and protective equipment.

Environmental performance plays an increasingly important role as global manufacturers transition to more sustainable product lines. The new fabric fits neatly within that movement, offering a practical option for companies looking to improve both comfort and eco-friendly credentials.

Applications Beyond Heat Protection

While the fabric’s immediate benefit lies in cooling and moisture management, its potential extends far wider. The researchers believe it could easily be adapted for sportswear, uniforms and specialist protective clothing. Extreme heat conditions are a challenge for emergency responders, military units and construction crews, where better cooling can help reduce fatigue and improve safety.

The textile’s characteristics also align with global policy efforts focused on heat resilience. Cities, businesses and public agencies increasingly look for tools to safeguard vulnerable populations, especially those working outdoors. Heat-related illnesses continue to rise, and low-cost passive cooling solutions are in high demand.

Manufacturers may find considerable commercial opportunity in this technology, particularly as demand grows in regions most exposed to climate change. Even recreational markets such as hiking and adventure sports could benefit from improved thermal regulation.

Towards Large-Scale Production

Prof Ma and his colleagues are exploring the commercial potential of the technology. “The electrospinning process is straightforward and cost effective, which means the fabric could be produced at industrial scale,” he says. With further development, manufacturing could expand rapidly to meet the needs of multiple industries.

Scaling up would open the door to competitive production costs, especially as electrospinning continues to evolve. Modernised equipment, automated control systems and improved fibre formulations make mass production more viable than ever before. Large manufacturers already use similar approaches to produce filters, membranes and high-performance composites.

A Step Toward Heat-Resilient Workforces

The world’s workforce increasingly faces heat stress as a daily challenge. Climate projections from international agencies show continued temperature rises throughout the century. In that context, textiles like this one could improve personal safety while reducing reliance on energy-intensive cooling technologies.

Research in passive cooling materials continues to expand globally, with parallel developments in reflective coatings, phase change materials and thermally conductive polymers. This new fabric forms part of that broader ecosystem of innovation, providing practical, scalable solutions.

Designed For Real-world Environments

Further research and field testing will determine how the fabric performs in demanding real-world environments. Interest from manufacturers and government agencies could help move the technology into market-ready applications.

Extreme heat is an unavoidable part of daily life for millions, innovations like this offer a clear path toward safer and more comfortable conditions.