Lightweight Design Reinvented

Achieving the delicate balance between minimal weight and maximum robustness has long challenged engineers working across medical technology, automotive manufacturing, aerospace design and advanced industrial fabrication. Every gram trimmed from a structural component can unlock efficiency gains, improve fuel performance or reduce production costs. Yet weight reduction can never be allowed to undermine reliability or safety. This tension has driven decades of innovation in lightweight engineering, but comparing the diverse design philosophies has remained notoriously difficult.

Researchers at the Technical University of Munich have tackled this issue head-on. Their Stress-Guided Lightweight 3D Designs benchmark, known as SGLDBench, offers a unified reference system that evaluates a broad range of lightweight construction methods using a single transparent standard. The development marks an important milestone in how designers understand, compare and ultimately optimise their components.

Understanding the Lightweight Design Challenge

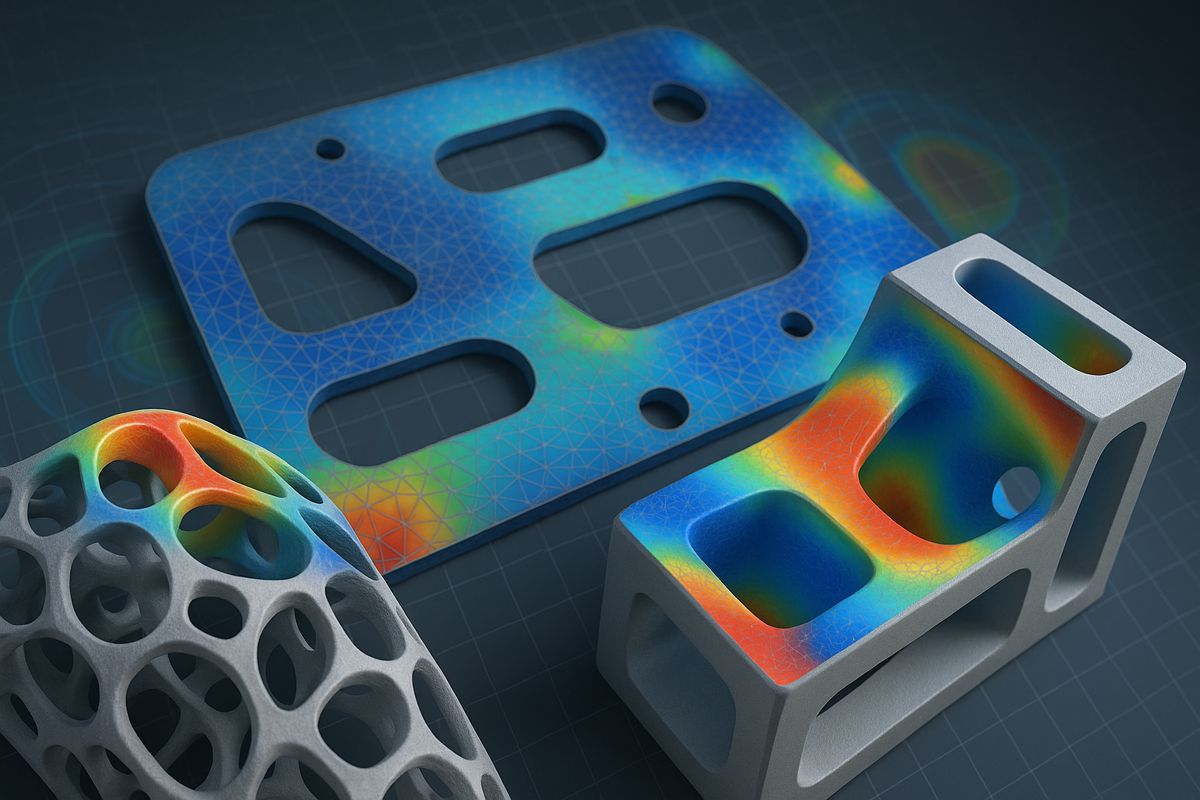

Lightweight components are typically created using computer-based techniques long before they reach production. Engineers turn to a variety of established methodologies including classical topology optimisation, gradient-based structural refinement, lattice frameworks and porous infill strategies. Each method uses a distinct physical and mathematical model, making direct comparisons extremely difficult.

These approaches often rely on complex calculations that restrict spatial resolution. As a result, many design simulations are constrained by hardware performance, forcing engineers to compromise between accuracy and computing time.

SGLDBench was created to remove these barriers. It delivers a structured platform where engineers can evaluate different lightweight design variants with consistent parameters and far greater computational efficiency.

A Benchmark Built for Industry Needs

The benchmark supports six key reference strategies, ranging from traditional optimisation techniques to cutting-edge lattice-based systems. Each methodology can be applied to any component, using user-defined boundary conditions and 3D simulations.

This flexibility is essential for industries where small adjustments in geometry, stiffness or connectivity can dramatically influence real-world performance. SGLDBench takes into account variables such as stiffness-to-weight ratio, stress distribution, deformability and how a part interacts with the assembly that surrounds it. By integrating these parameters, users can explore different resolutions, material uses and structural concepts without reinventing the design rules each time.

Researchers highlighted several industries where the tool will immediately prove useful. Hip implants, for example, can be modelled with multiple design variations before manufacturers commit to custom fabrication. This helps optimise load distribution and patient comfort. In automotive and aerospace engineering, the tool can guide the development of ultra-light components that still meet demanding crash and vibration resistance standards. Weight savings in these sectors have a direct impact on fuel consumption and emissions.

More Than 100 Million Simulation Elements

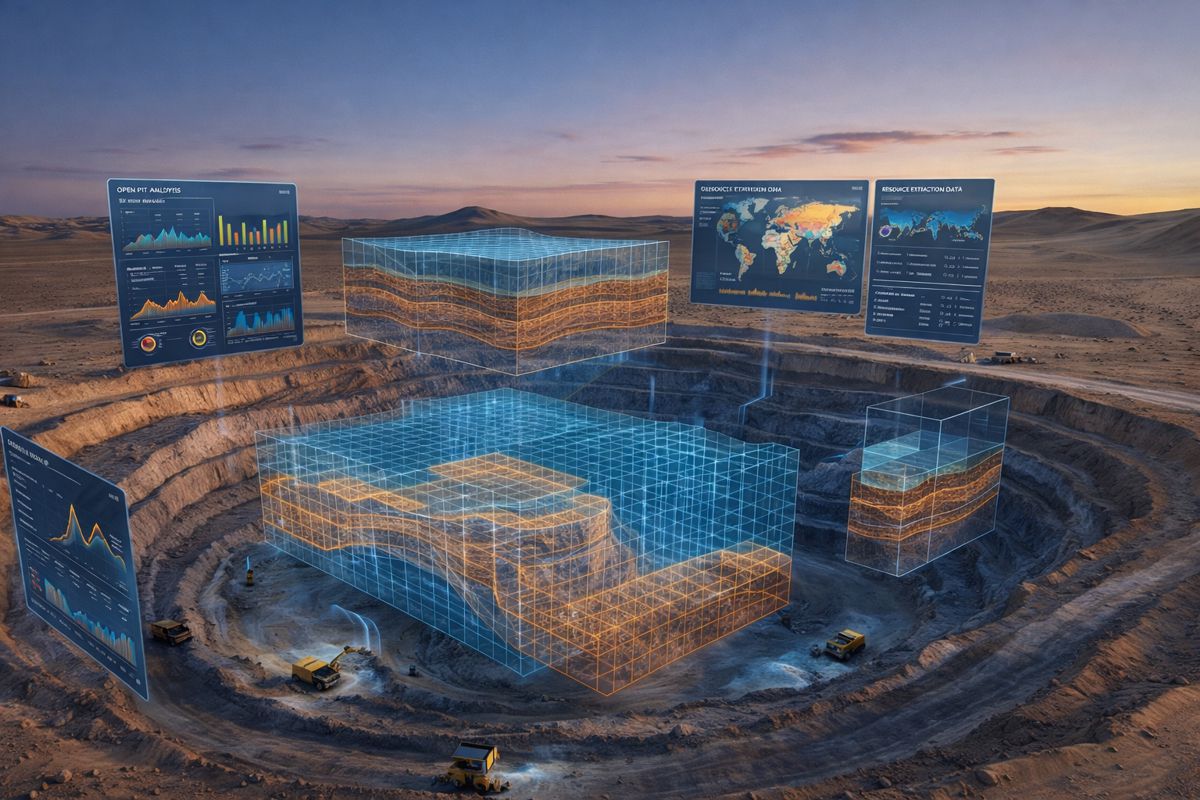

One of the most striking capabilities of SGLDBench is its ability to run simulations using more than 100 million elements on standard desktop computers. That level of detail has traditionally required specialised engineering workstations or clusters.

Rüdiger Westermann, Professor for Computer Graphics and Visualization at the TUM School of Computation, Information and Technology, emphasised the impact of this achievement. “With SGLDBench we have created a transparent benchmark for lightweight design:” he said. “That will not only help researchers with the classification of methods, but will also give companies a tool for reaching well-founded decisions in product development.”

He added that the speed of the system marks a breakthrough. “At present, SGLDBench can perform simulations with more than 100 million elements on an affordable desktop computer in much faster times than commercial products.”

What Makes the System So Efficient?

Behind SGLDBench lies an array of algorithmic advances designed to make stress simulations more effective. The team developed new approaches for solving large systems of equations and tailored these methods for common computer architectures. By reducing memory demand and streamlining processing steps, they enabled simulations that were once considered impractical outside of high-performance computing environments.

This efficiency opens the door to broader adoption. Small engineering firms, university labs and manufacturing teams can integrate high-resolution simulations into their everyday workflows without purchasing specialised hardware. For industries operating with tight budgets or rapid development cycles, this accessibility could reshape design pipelines.

Where Lightweight Design Is Heading

The global shift toward electrification, sustainable mobility and resource-efficient manufacturing has intensified interest in lightweight engineering. Electric vehicles, for instance, depend on weight reduction to extend their range. Aerospace manufacturers are under growing pressure to lower emissions by designing lighter aircraft. Meanwhile, medical device makers are exploring advanced lattice structures that mimic organic tissue while maintaining strength.

International research also shows a rising trend towards multi-material systems, where composites, metals and polymers are strategically combined to optimise performance. SGLDBench provides a valuable framework for testing such hybrid concepts. By comparing how different materials respond within identical boundary conditions, engineers can spot weaknesses and opportunities far earlier in the design process.

A Platform for Future Innovation

As digital engineering matures, tools like SGLDBench will play an increasingly central role. The benchmark encourages repeatable, transparent evaluation, enabling both researchers and manufacturers to collaborate on shared datasets and validated models. It may also help accelerate advances in generative design, where AI-driven algorithms produce component shapes that human designers might never conceive.

This level of standardisation has the potential to improve regulatory approvals, quality assurance and cross-industry interoperability. For sectors such as aviation and healthcare where safety is paramount, improvements in testing rigour can directly enhance public confidence.

Moving Lightweight Design Forward

The development of SGLDBench marks a decisive step toward better, more dependable lightweight engineering. It offers a practical tool for comparing design strategies, clarifying performance metrics and pushing simulations to unprecedented resolutions without significant hardware investment.

By bridging the gap between diverse methodologies, SGLDBench gives engineers a common language to assess innovations and refine complex components. In doing so, it strengthens the foundations of industries that depend on precise, resilient and efficient designs.