Accelerating Road and Bridge Rehabilitation with Hydrodemolition

Ageing bridges across the United States are now reaching critical condition. According to the American Road & Transportation Bridge Association, more than one in three U.S. bridges need significant rehabilitation or complete replacement. More than 220,000 structures fall into this category, representing years of intensive work for highway contractors and infrastructure professionals.

With federal support from the Bipartisan Infrastructure Law, bridge maintenance has finally received long-awaited funding. However, even with billions set aside, the challenge remains daunting. The construction sector continues to struggle with labour shortages, extended project timelines, and the ever-present need to minimise public disruption. Contractors are therefore prioritising technology that speeds up structural work without reducing safety or long-term durability.

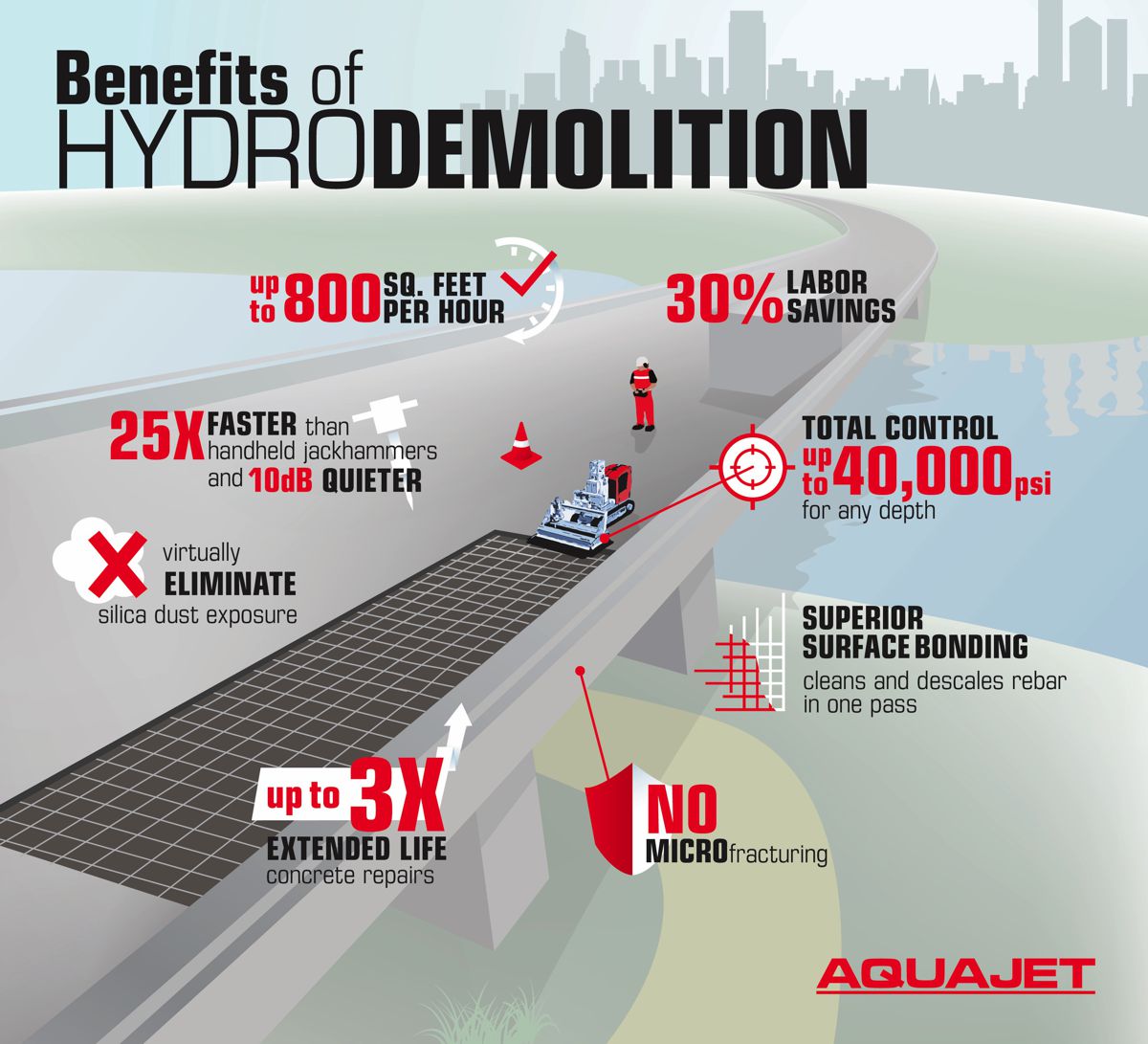

Hydrodemolition is emerging as one of the preferred methods for large-scale concrete removal, rivalling traditional breaking techniques. Its combination of speed, safety, precision and reduced labour requirements has made it particularly attractive for highway and bridge contractors seeking to complete more work within compressed schedules.

What Makes Hydrodemolition Different?

Hydrodemolition is a controlled method of removing concrete using robotically operated high-pressure water jets. Pressures can reach up to 40,000 psi, and in many applications the concrete is disintegrated by widening its existing pores. Instead of chipping or breaking the structure with impact tools, Hydrodemolition forces the concrete to fracture naturally.

Traditional mechanical removal methods cause microfracturing, vibration transmission and unintentional rebar damage. Hydrodemolition eliminates those issues entirely. No impact means the underlying structural elements and reinforcing steel remain intact and undisturbed.

Hydrodemolition delivers:

- Zero vibration and no microfractures

- Complete cleaning and descaling of rebar

- An ideal bonding profile for new concrete overlays

- Precision removal that protects remaining structural strength

Once damaged material is removed, the substrate is prepared with a rough, consistent texture that promotes excellent bonding between the old surface and new concrete. These benefits directly influence overall longevity, making repairs more durable and therefore highly cost-effective over the life of the asset.

Industry studies indicate that properly executed Hydrodemolition repairs routinely outperform mechanical removal in terms of water tightness, bonding strength and overlay durability. Many bridge engineers now prefer Hydrodemolition whenever significant concrete replacement is involved.

Speed and Productivity Gains

Time savings may be one of the most compelling advantages. Hydrodemolition can be up to 25 times faster than manual removal using hammer breakers or hand lances, and it requires far fewer labour hours.

A single operator can complete large sections of concrete removal more efficiently than multiple labourers using handheld tools. Some Hydrodemolition robots are capable of stripping up to 800 square feet of concrete bridge deck to a depth of 4 inches in one shift, representing a fraction of the labour hours normally required.

Unlike jackhammers or concrete milling tools, Hydrodemolition robots operate consistently for long periods without fatigue, keeping productivity high throughout the shift. They also eliminate costly tool maintenance and frequent consumable replacement.

For contractors working under tight lane-closure windows, productivity becomes mission-critical. A shorter construction schedule means fewer closures, less traffic congestion and a smaller impact on road users. Departments of transportation increasingly assign value to reduced traffic delay costs when evaluating tenders, and Hydrodemolition offers measurable benefits in this regard.

Versatility Across All Bridge Components

Hydrodemolition is far more flexible than many contractors initially assume. With the correct work packages and accessories, a single robot can perform removal on bridge decks, parapets, soffits, girders and vertical columns.

Tools such as extension arms, elbows and rotating heads allow the robot to reach more than 8 feet below its tracks while still operating from the deck. This enables work on structural faces without dismantling parapet railings or building secondary access scaffolding.

Other accessories expand functionality even further:

- Rotating tools for surface preparation and membrane removal

- Circular powerheads for consistent 360-degree removal on columns

- Configurable frames for elevated or underside concrete stripping

Contractors gain operational flexibility by avoiding specialised machinery for each bridge element. This single-machine work approach reduces capital cost, transport requirements and on-site congestion.

Safety Enhancements for Labour and Public Traffic

Hydrodemolition significantly improves operator safety and site safety. One of the most valuable features is remote operation. Labourers can control the robot away from debris, edges, heavy vibration, airborne dust and traffic. Instead of performing removal while leaning over parapets, operators supervise the work from secure locations.

The compact footprint allows the machine to operate within a single lane, which reduces the need for full closures and limits exposure to moving vehicles. Contractors lower their risk profile significantly when workers are not positioned near live traffic edges.

Manual breaking tools present additional hazards. A worker using a 40,000-psi hand lance must resist a back thrust of up to 52 pounds. Over a full shift, this becomes physically demanding and can lead to fatigue, musculoskeletal injuries and lost work hours. Jackhammers expose workers to continuous vibration, which can cause hand-arm vibration syndrome and progressive numbness, impacting grip strength and dexterity.

Hydrodemolition robots eliminate these risks entirely, allowing workforces to remain healthier and more productive across long project durations.

Hydrodemolition also reduces silica dust exposure. Traditional concrete breaking releases airborne crystalline silica, exposing labourers to significant respiratory hazards associated with lung cancer, silicosis and kidney disease. Since Hydrodemolition relies on water to disintegrate the concrete, dust never becomes airborne. Remote operation further distances workers from any residual particulate.

Infrastructure owners increasingly prefer methods that enhance worker health. Safer methods also improve insurance outcomes, reduce compensation events and decrease long-term workforce attrition.

Environmental and Asset Lifecycle Improvements

Hydrodemolition introduces environmental benefits beyond worker health and safety. Water-based removal produces far less airborne contamination, making it suitable for enclosed structures, water crossings, marine assets or high-traffic metro bridges.

Since the process is impact-free and non-abrasive, the rebar remains in good condition without requiring replacement, galvanising or post-treatment. Cleaning the reinforcing steel naturally extends the structure’s lifecycle without adding significant material cost or downtime.

From a sustainability angle, Hydrodemolition contributes to lower embodied carbon over the life of an asset. By extending service life and reducing premature overlay failures, it helps reduce overall material consumption and subsequent rehabilitation cycles.

Surface bonding achieved with Hydrodemolition also improves overlay performance. New concrete adheres more consistently to a properly prepared substrate, resisting delamination or cracking over many years of service.

Global Expansion and Market Leadership

Aquajet has become one of the best-known manufacturers of Hydrodemolition robots and has achieved broad global adoption. Acquired by Brokk AB in 2016, Aquajet benefits from Brokk’s established network in controlled demolition and robotic construction equipment. Its headquarters and production facilities are located in Holsbybrunn, Sweden, with a strong international dealer network.

The company’s product portfolio includes advanced bridge-focused Hydrodemolition robots, ultra-high-pressure systems, and a full range of accessories for columns, elevated girders and complex geometries. Aquajet remains widely used in bridge rehabilitation, quay walls, hydropower dams, marine piers, concrete tunnels and municipal infrastructure.

Brokk’s extensive robotic demolition knowledge, combined with Aquajet’s engineering expertise, continues to influence the industry’s direction. Many bridge engineers who once relied on mechanical removal are now specifying Hydrodemolition directly in tender documentation.

Working Smarter and Delivering Better Outcomes

With the enormous volume of bridge repairs now required across the United States, equipment selection has become a decisive factor affecting project timetables, cost efficiency and outcomes. Hydrodemolition delivers value on several fronts: speed, labour optimisation, safety, bonding quality, lifecycle improvement and reduced dust exposure.

Contractors consistently report improved productivity, better surface integrity and a more controlled operating environment. Infrastructure owners gain structures that perform longer, resist water penetration more effectively and require fewer early maintenance events.

Hydrodemolition enables highway and bridge contractors to achieve better outcomes without relying on increasingly scarce labour pools. The approach helps the industry continue modernising while protecting workers and the travelling public. At a time when every hour, lane closure and safety exposure matters, Hydrodemolition is rapidly shaping how concrete rehabilitation is delivered.