Smarter Automation for Material Handling

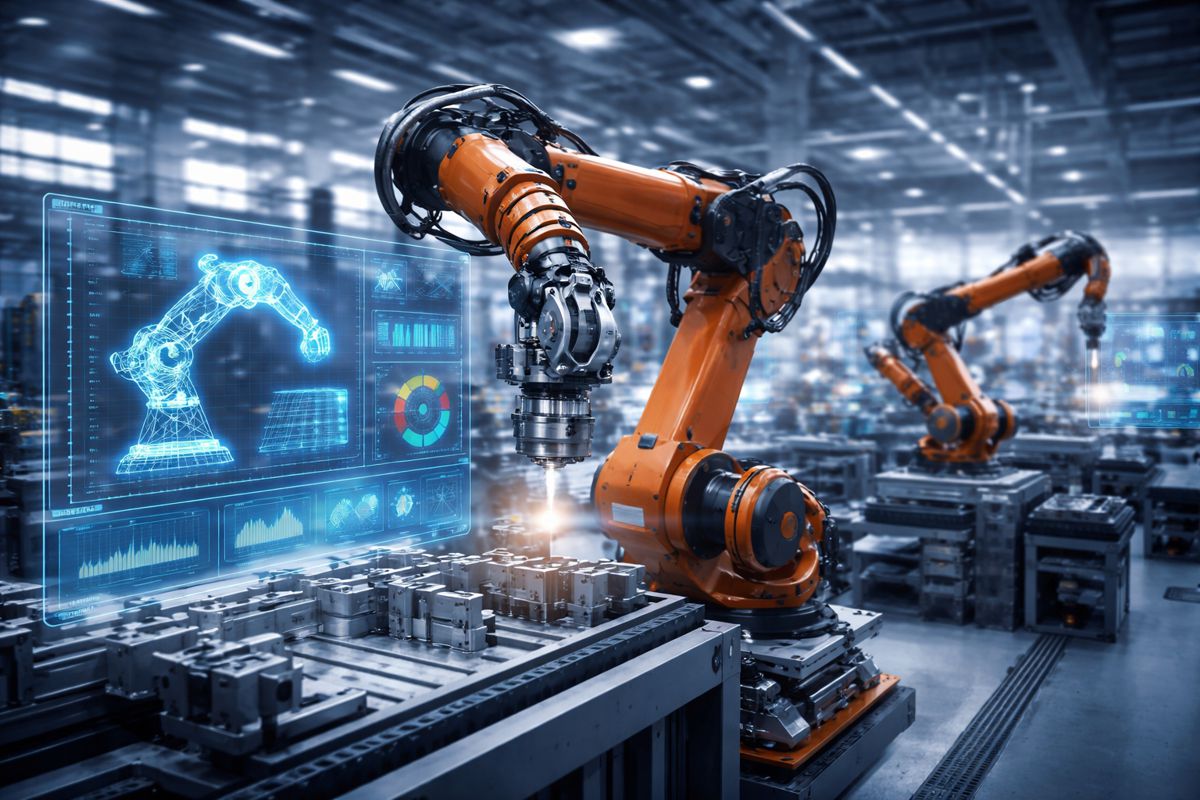

Automation in industrial logistics has moved well beyond simple mechanisation. Warehouses and factories are now expected to operate with the awareness, responsiveness and efficiency of digital ecosystems. Against that backdrop, the strategic collaboration between Aptiv PLC and Vecna Robotics signals a significant shift in how autonomous material handling systems are designed, deployed and scaled.

Both companies arrive at this partnership with complementary strengths. Aptiv brings a deep portfolio of perception, compute and embedded software technologies proven in demanding automotive and industrial environments. Vecna Robotics contributes AI-driven autonomy and orchestration capabilities that have already demonstrated tangible results in live warehouse and factory operations. Together, they are targeting a long-standing challenge in automation, delivering advanced Autonomous Mobile Robots that are not only safer and smarter, but also cost efficient and practical to deploy.

The Industrial Context Driving Smarter Automation

Global supply chains have become more complex and less forgiving. Labour shortages, rising operating costs and increasing expectations around safety and throughput have pushed operators to rethink traditional material handling. Fixed automation systems, once the default option, often struggle to adapt when layouts change or demand fluctuates.

Autonomous Mobile Robots have emerged as a flexible alternative, yet many deployments still face limitations. High upfront costs, rigid infrastructure requirements and difficulties operating in mixed traffic environments have slowed adoption. The Aptiv and Vecna Robotics collaboration is aimed squarely at these pain points, combining advanced sensing, real time intelligence and orchestration to make AMRs more adaptable and economically viable at scale.

Advanced Perception as the Foundation

At the heart of the joint solution is Aptiv’s advanced perception portfolio, designed to allow machines to sense their surroundings with a high degree of confidence. Reliable perception is not optional in industrial environments where people, forklifts and robots often share the same space.

A central element is the award winning PULSE™ sensor, a compact surround view camera system paired with an ultra short range radar. This combination enables accurate 360 degree awareness, even in environments where lighting conditions, reflective surfaces or clutter can confuse traditional vision systems. By fusing camera and radar data, the system maintains situational awareness in conditions that would otherwise degrade performance.

Machine Learning for Real Time Decision Making

Perception alone is only part of the equation. Industrial environments are dynamic by nature, with constantly changing obstacles, workflows and priorities. To handle this complexity, the joint solution integrates Aptiv’s radar based machine learning and behaviour modelling technologies.

These ML driven capabilities support real time perception and dynamic path planning, allowing robots to respond intelligently rather than follow pre programmed routes. Instead of stopping or rerouting unnecessarily, AMRs can make nuanced decisions based on context, improving flow and reducing bottlenecks. Over time, learning based systems also open the door to continuous improvement as robots adapt to patterns in traffic and operations.

Autonomy Designed for Mixed Traffic Environments

Vecna Robotics’ autonomy platform has been developed with real world industrial conditions in mind. Warehouses and factories rarely offer the controlled environments seen in demonstrations. People move unpredictably, forklifts operate at speed and layouts evolve as operations change.

The Vecna platform prioritises safety through advanced perception and fail safe navigation systems that detect and avoid obstacles in real time. Crucially, this capability extends to mixed traffic environments where humans and machines interact continuously. Rather than isolating robots from people, the system is designed to operate alongside them without disruption.

Orchestrating Workflows Beyond the Robot

Autonomy alone does not guarantee efficiency. Material handling is a system level challenge that involves people, vehicles and processes. Vecna Robotics addresses this through its CaseFlow™ integration, which orchestrates workflows across robots, forklifts and human workers.

This orchestration layer ensures tasks are prioritised intelligently, balancing throughput and safety while minimising idle time. By integrating with existing warehouse management and execution systems, CaseFlow allows automation to enhance operations rather than forcing costly process redesigns. The result is improved flow without the upheaval often associated with new technology deployments.

Embedded Compute Built for Industrial Demands

Running advanced perception and autonomy algorithms requires robust compute platforms capable of real time performance. Aptiv’s embedded software and compute architecture underpins the joint solution, providing the reliability and scalability expected in industrial applications.

Built on Aptiv’s high performance compute platform, the system incorporates the VxWorks real time operating system and the Wind River Helix Virtualization Platform. This combination delivers ultra low latency, advanced virtualisation and flexibility to support multiple system designs. For operators, that translates into dependable performance today and adaptability for future upgrades.

Delivering Practical, Cost Efficient Automation

One of the most significant aspects of the collaboration is its focus on cost efficiency. Advanced automation has often been associated with high capital expenditure and long payback periods. By integrating perception, autonomy and orchestration into a cohesive platform, Aptiv and Vecna Robotics aim to lower the barriers to entry.

Vecna Robotics’ AMRs are designed to deploy without fixed infrastructure, reducing installation time and cost. The ability to scale incrementally allows operators to start small and expand as confidence and demand grow. This approach aligns automation investment more closely with operational realities and return on investment expectations.

Industry Perspectives from the Leadership

Aptiv sees the partnership as a natural extension of its expertise in intelligent systems applied beyond automotive applications. Javed Khan, Executive Vice President, Intelligent Systems at Aptiv, highlighted the broader vision behind the collaboration: “Automation is transforming the way goods move through warehouses and factories, with devices that sense, think and act in real time. Our collaboration with Vecna Robotics combines Aptiv’s advanced perception, compute, and software solutions with Vecna’s proven expertise in autonomous material handling. Together, we’re making automation safer, smarter, and more affordable—helping customers meet the demands of modern logistics.”

From Vecna Robotics’ perspective, the partnership strengthens its ability to deliver measurable outcomes for customers. Karl Iagnemma, Chief Executive Officer at Vecna Robotics, emphasised the practical benefits: “Partnering with Aptiv enables us to deliver even more robust and cost-optimized robotic products. This collaboration strengthens our ability to help customers reduce operational costs, improve throughput, and achieve faster, more scalable automation ROI. By combining our AI-driven autonomy and orchestration with Aptiv’s advanced perception and compute technologies, we’re enabling more efficient workflows, safer operations, and meaningful cost savings for customers seeking to modernize without major infrastructure investment.”

Implications for Warehousing and Manufacturing

The collaboration arrives at a time when industrial operators are reassessing their automation strategies. Rather than pursuing isolated technologies, there is growing recognition that integrated systems deliver better outcomes. Perception, intelligence, compute and orchestration must work together to handle the complexity of modern operations.

By addressing safety, scalability and cost in parallel, the Aptiv and Vecna Robotics solution reflects this systems level thinking. For warehouses and factories under pressure to do more with less, such approaches offer a more sustainable path to automation.

Autonomous Material Handling

As automation continues to evolve, expectations will rise. Robots will be judged not only on their technical capabilities, but on how seamlessly they integrate into existing operations. Partnerships that combine deep technology expertise with operational insight are likely to shape the next phase of adoption.

Together, Aptiv and Vecna Robotics are positioning autonomous material handling as a practical, scalable and economically sound option for industrial operators. By redefining what AMRs can sense, decide and coordinate, the collaboration lays a stronger foundation for the future of logistics and manufacturing.