Smarter Simulation for Industrial 3D Printing

Industrial additive manufacturing has long promised lighter parts, faster iteration and supply chain resilience. Yet for safety critical and load bearing polymer components, confidence has often come at a cost. Engineers either overbuilt parts to stay safe or relied on repeated physical testing to qualify designs. Both approaches slowed adoption and eroded the very efficiencies additive manufacturing set out to deliver.

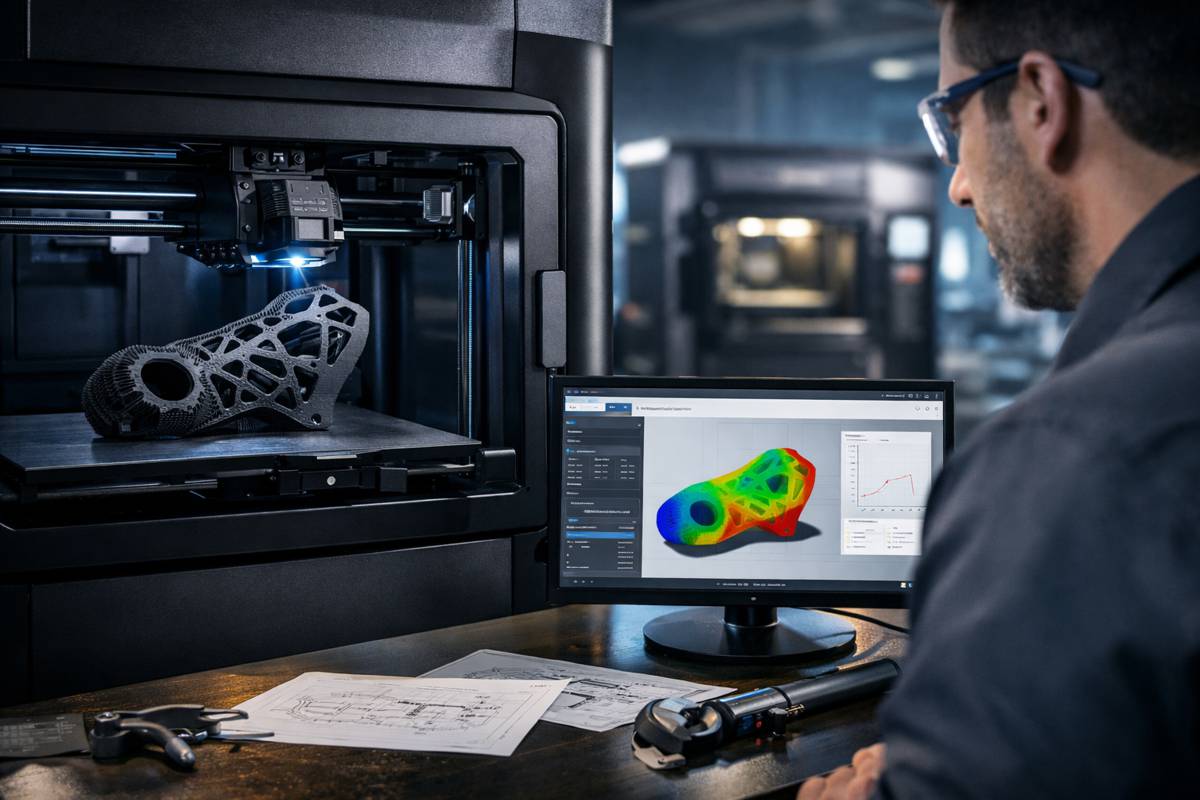

That gap is now being addressed through a new software integration announced by Stratasys Ltd. and Novineer. By embedding Novineer’s NoviPath polymer performance simulation directly into GrabCAD Print Pro software, the two companies are aiming to bring predictability and engineering confidence into the heart of industrial FDM workflows. The integration enables engineers to simulate how parts will behave in the real world before printing, using the same toolpath data that drives the printer itself.

Why Traditional Simulation Has Fallen Short

Conventional finite element analysis tools were never designed with layer by layer material extrusion in mind. In most cases, they treat printed components as uniform, isotropic solids. That assumption breaks down quickly for FDM parts, where build orientation, bead direction, infill strategy and interlayer bonding all play a decisive role in performance.

As a result, engineers have struggled to predict stiffness, strength and failure behaviour accurately. Trial and error testing became the norm, particularly in regulated sectors such as aerospace and automotive. While workable, this approach added weeks to development cycles and pushed costs upward, especially when qualification demanded multiple physical iterations.

Bridging Design Intent and Printed Reality

The Stratasys and Novineer integration takes a fundamentally different approach. NoviPath uses GrabCAD toolpath data to simulate how an FDM part behaves once printed. Rather than abstracting away the manufacturing process, the simulation accounts for it directly, capturing build orientation, layer direction, infill patterns and material specific properties.

Ali Tamijani, Ph.D., CEO and Co-Founder of Novineer, described the significance of the move clearly: “Partnering with Stratasys embeds NoviPath’s toolpath-aware part simulation into GrabCAD Print Pro, bridging the gap between design intent and real-world part performance.”

That shift from assumption to process awareness is the cornerstone of the solution. Engineers can now see how design decisions translate into physical behaviour before committing time and material to a build.

Quantifiable Gains in Weight and Performance

Early users of the technology have already reported meaningful results. By accurately predicting load paths and failure points, teams have achieved weight reductions of up to 35 percent on load bearing polymer parts. Crucially, these savings come without compromising part quality or safety margins.

Such reductions carry implications beyond material cost. Lighter parts typically mean faster build times, lower energy use and reduced downstream assembly loads. In sectors where every gram matters, particularly aerospace and high performance automotive applications, these gains quickly compound.

Victor Gerdes, Vice President of Software at Stratasys, highlighted the impact on everyday engineering practice: “Engineers often over-design FDM parts or rely on trial-and-error testing because they don’t have an easy and accessible simulation solution to predict part performance.”

By bringing validated simulation into the print preparation stage, Stratasys aims to make performance driven design the default rather than the exception.

A Unified Workflow Inside GrabCAD Print Pro

One of the more practical strengths of the integration lies in its workflow continuity. NoviPath operates entirely within GrabCAD Print Pro, allowing users to launch simulations using the same toolpath data that will ultimately drive the printer. There is no need to export models, rebuild meshes or translate assumptions between software environments.

Engineers can define application specific load cases, apply safety factors and identify likely failure locations. Iteration happens virtually, with rapid feedback enabling performance targets to be met before the first part is printed. Validation that once took weeks can now be compressed into hours.

This closed loop approach reduces friction across teams, particularly in organisations where design, manufacturing and validation are tightly coupled.

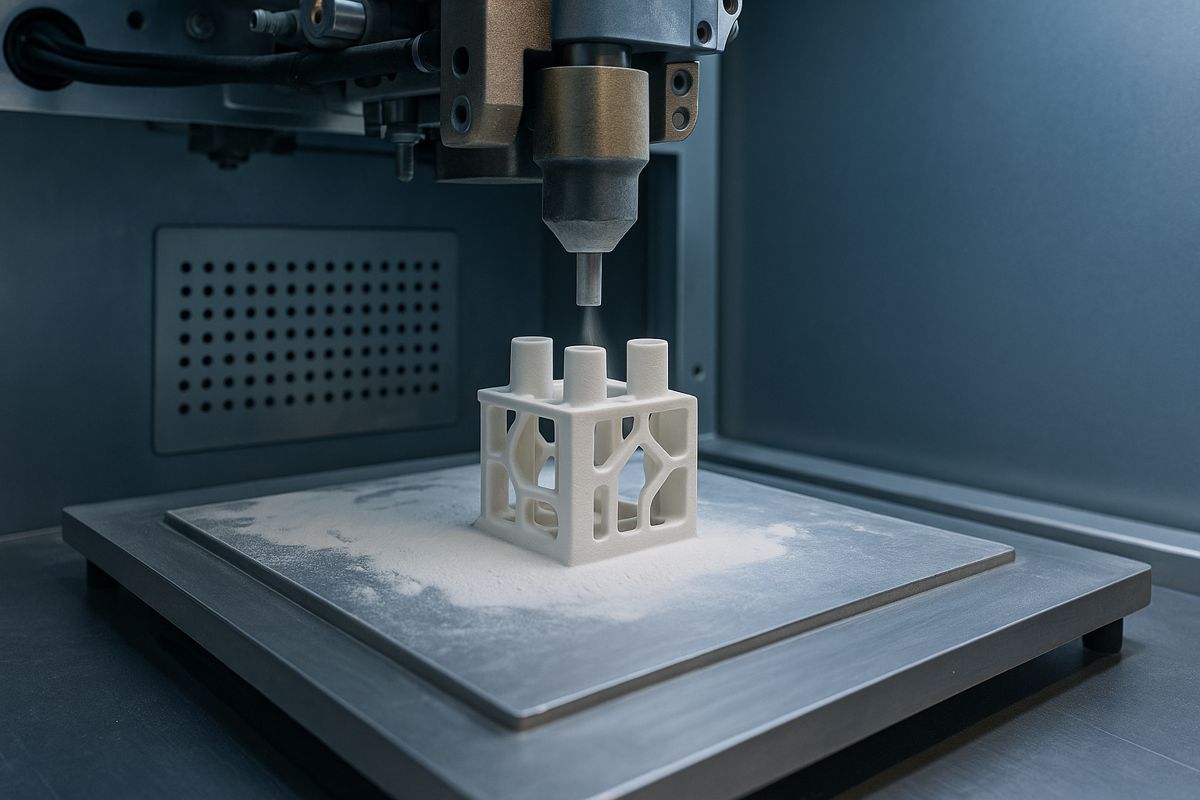

Supported Platforms and Materials

Initial support for the new simulation capability is expected across several of Stratasys’ flagship industrial FDM systems. These include the F3300, the F900 and the Fortus 450mc platforms. A broader expansion roadmap is already in place, signalling intent to make toolpath-aware simulation a standard feature across the portfolio.

Material validation is equally central to the strategy. The integrated solution will launch with a validated material library covering Antero 800NA, FDM Nylon 12CF and ULTEM 9085 filament. Additional materials are planned as the ecosystem evolves, reinforcing confidence in performance predictions across an expanding range of applications.

Extending the Industrial FDM Ecosystem

With this integration, Stratasys is extending its software ecosystem beyond print preparation and machine control. The aim is to support the full engineering workflow, from initial design through performance validation and into production.

For engineering teams, the combined solution delivers several tangible advantages:

- The ability to identify failure points and load limits before printing

- Proven accuracy enabling weight reductions of up to 35 percent on critical parts

- Faster time to production by reducing validation cycles from weeks to hours

- Lower total cost through lighter parts, faster builds and reduced physical testing

Together, these benefits address many of the barriers that have historically limited the use of polymer additive manufacturing in production environments.

Availability and Early Access Plans

FDM performance simulation within GrabCAD Print Pro is planned to be introduced through a joint Stratasys and Novineer early access pilot programme in the second quarter of 2026. This phased approach allows both companies to refine workflows, expand material libraries and validate performance across real world use cases before broader release.

Such pilots are increasingly common in industrial software, reflecting the complexity of production environments and the need for confidence before full scale deployment.

Novineer’s Broader Digital Engineering Vision

The NoviPath integration forms part of a wider platform strategy at Novineer. The company is positioning itself as a catalyst for faster, more reliable digital engineering by radically reducing the time and expertise required to move from concept to production ready models.

Its platform includes NoviVision for photo to CAD model generation, NoviDesign for generative design and optimisation, and NoviPath for toolpath aware simulation. Together, these tools aim to reduce trial and error, accelerate reverse engineering and validate feasibility earlier in the development cycle.

Organisations adopting these tools are seeking to de-risk innovation while maintaining pace, a balance that has become increasingly critical as product lifecycles shorten.

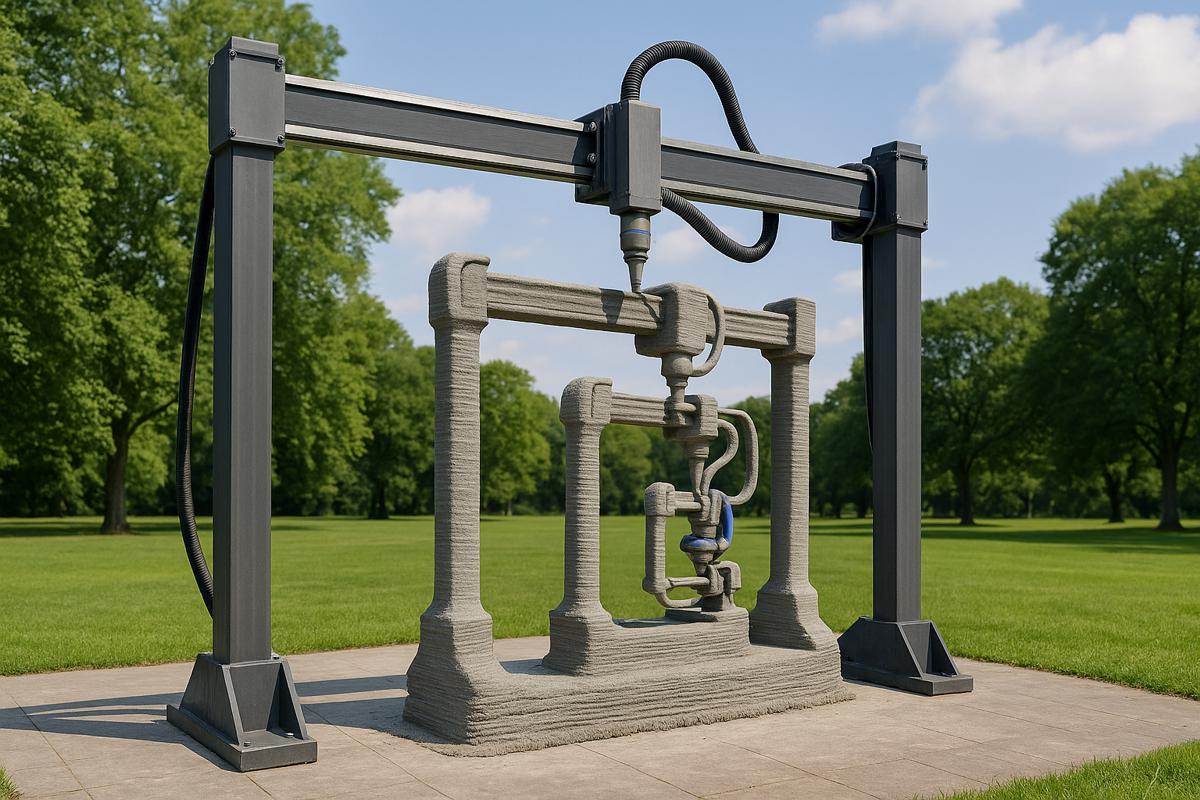

Stratasys and the Industrial Additive Manufacturing Landscape

Stratasys continues to position itself at the forefront of polymer additive manufacturing, serving industries ranging from aerospace and automotive to consumer products and healthcare. Its strategy increasingly centres on connected systems, validated materials and software driven workflows that extend beyond the printer itself.

By integrating simulation directly into its print preparation environment, Stratasys is reinforcing a message that additive manufacturing is no longer just about making parts. It is about engineering them with the same rigour and predictability expected of traditional production methods.

As additive manufacturing continues its shift from prototyping to production, tools that reduce uncertainty will play a decisive role. Toolpath aware simulation represents a meaningful step in that direction, aligning digital intent with physical reality and giving engineers greater confidence in every printed layer.