Electrifying Steel Heat Treatment for Industrial Decarbonisation

Industrial decarbonisation has shifted from policy ambition to operational necessity. Across energy intensive sectors, steel in particular, pressure is mounting to eliminate fossil fuels from core processes without sacrificing productivity or quality. Against this backdrop, a research breakthrough from the Korea Institute of Energy Research offers a glimpse of what carbon free metal processing could look like in practice.

Led by Dr. Hookyung Lee, researchers at KIER have developed an electrified heat treatment technology that replaces fossil fuel combustion with electricity in the annealing process used for galvanised steel strip production. Designed for automotive and household appliance steels, the system has already demonstrated dramatic emissions reductions under conditions that closely mirror real world production.

Policy Pressure Driving Process Electrification

South Korea’s industrial sector is facing a decisive decade. The government has accelerated its push to decarbonise manufacturing, placing electrification of industrial heat firmly at the centre of national climate strategy. At the 5th Plenary Meeting of the Presidential Committee on Carbon Neutrality and Green Growth in November 2025, an ambitious target was reaffirmed.

The industrial sector has been tasked with achieving up to a 31 percent reduction in emissions compared with 2018 levels. This reduction is expected to come from decarbonising feedstocks and fuels, electrifying processes, and scaling up the production of low carbon industrial products. For steelmakers, whose furnaces traditionally rely on natural gas or other fossil fuels, the challenge is formidable.

Why Galvanised Steel Matters

Galvanised steel strip sits quietly at the heart of modern life. It is used extensively in automotive body panels, white goods, construction components, and countless manufactured products. Its corrosion resistance and mechanical performance depend heavily on precise heat treatment during production.

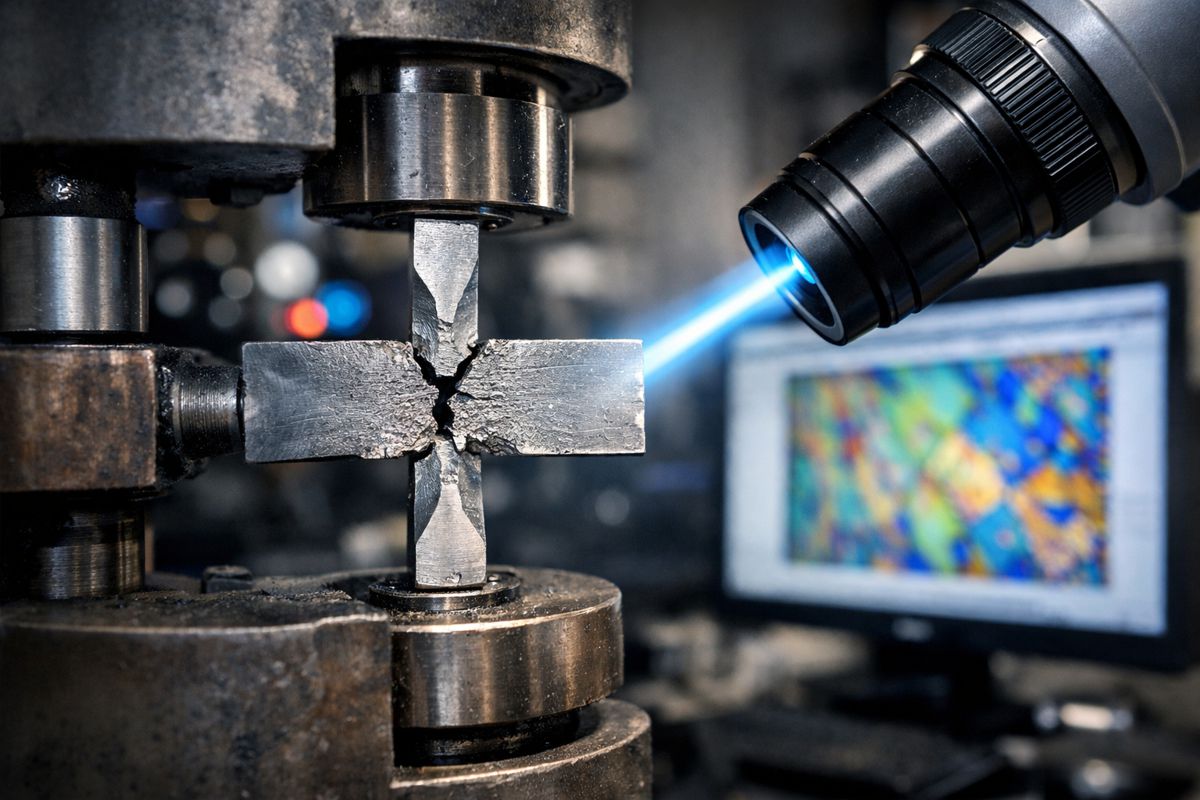

Production typically takes place on a Continuous Galvanizing Line, commonly known as a CGL. Steel strip is continuously fed through a molten zinc bath, but before coating, it undergoes annealing. This controlled heating and cooling process improves ductility and formability, ensuring the steel performs reliably during downstream forming and assembly.

The Carbon Cost of Conventional Annealing

Traditionally, annealing furnaces in CGL operations are fired using natural gas. While effective and well understood, combustion based heating brings unavoidable environmental consequences. Large volumes of carbon dioxide are released, along with nitrogen oxides that contribute to air pollution.

In South Korea alone, carbon dioxide emissions from the steel industry, including zinc related processes, account for roughly 15 percent of total national emissions. That figure has placed steelmaking squarely in the crosshairs of climate policy, both domestically and internationally.

Inside the Carbon Free Annealing System

Rather than redesigning the entire furnace from scratch, the KIER team took a pragmatic engineering approach. Their carbon free annealing system retains much of the existing furnace architecture, including the refractory structure and steel strip conveying mechanisms used in conventional combustion furnaces.

The crucial change lies in replacing burners with electric heating elements installed on both the upper and lower sections of the furnace. By carefully controlling the distance between these elements and the moving steel strip, the system delivers rapid, uniform heating through high temperature radiant energy, while minimising heat loss to the furnace walls.

Proven Performance Under Industrial Conditions

Laboratory success means little without industrial relevance. To address this, the research team tested the system under operating conditions closely aligned with commercial production. Steel strip with a thickness of 0.49 millimetres was annealed at 750 degrees Celsius, a demanding yet typical requirement for galvanised products.

The outcome was telling. The colour, microstructure, and mechanical properties of the steel were indistinguishable from material processed using conventional gas fired furnaces. At the same time, concentrations of carbon dioxide and nitrogen oxides in the exhaust gas were reduced by more than 98 percent.

Productivity Without Compromise

One of the persistent concerns surrounding electrification is whether it can deliver the same throughput and reliability as combustion based systems. In this case, the evidence suggests it can. The electric annealing furnace maintained productivity levels comparable to existing industrial furnaces, demonstrating that decarbonisation does not have to come at the expense of output.

These findings underline an important point for steelmakers. With appropriate equipment design and operating conditions, deep emissions reductions are achievable without altering product specifications or disrupting established production lines.

Lower Capital Costs and Smaller Footprint

Beyond emissions performance, the electrified furnace brings notable practical advantages. Because it does not require fuel and air supply systems, burners, or large exhaust installations, the overall system is simpler and more compact.

According to the research team, this translates into a reduction in capital investment costs and installation footprint of approximately 40 percent compared with conventional combustion furnaces. For operators facing tight margins and space constraints, those savings could prove decisive.

Aligning with Global Carbon Regulation

The strategic value of electrified heat treatment extends well beyond national policy. As global climate regulation tightens, manufacturers exporting steel products face increasing scrutiny of embedded carbon emissions.

One of the most significant developments is the Carbon Border Adjustment Mechanism, which imposes an additional carbon price on certain products imported into the European Union. The aim is to ensure that imported goods face a carbon cost equivalent to products manufactured within the EU. For exporters, low carbon production is fast becoming a competitive necessity rather than a marketing advantage.

Renewable Power Unlocks True Carbon Free Steel

The electric annealing system reaches its full potential when powered by renewable electricity. When supplied by wind or solar energy, the process can operate without direct carbon emissions, effectively delivering carbon free heat treatment.

This opens the door to compliance with the most stringent environmental regulations while positioning steelmakers to meet customer demand for low carbon materials. It also aligns closely with corporate net zero commitments that increasingly extend across entire supply chains.

A Platform for AI Driven Optimisation

While the current system already represents a major step forward, the researchers see further opportunity for refinement. Speaking about the broader implications of the work, Dr. Lee highlighted the potential for intelligent automation: “This demonstration is the world’s first case to show that carbon free heating can be achieved simply by replacing burners with electric heating elements.”

He added: “Moving forward, we plan to expand the technology into an AI based design and operation system that automatically recommends optimal heating element configurations based on steel strip width, thickness, and conveying speed, ultimately developing it into an export ready carbon free heating solution linked to commercial scale demonstrations with domestic steelmakers and overseas markets.”

From Demonstration to Deployment

The study was published in Applied Thermal Engineering in September 2025, and the research was supported by Korea’s Ministry of Trade, Industry and Energy, and the demonstration trials were carried out at the facilities of Samwoo Eco Co., Ltd. in close collaboration with industry partners.

This combination of public funding and private sector involvement strengthens the pathway towards commercial adoption.

Implications for Heavy Industry Worldwide

Although the technology was developed with galvanised steel strip in mind, its broader relevance is clear. Any industry reliant on high temperature heat treatment could potentially benefit from electrified furnace designs, from aluminium processing to advanced materials manufacturing.

As governments worldwide tighten emissions targets and introduce carbon pricing mechanisms, solutions that combine environmental performance with economic logic will stand out. Electrified annealing, as demonstrated by KIER, offers a compelling example of how incremental engineering changes can deliver transformational outcomes.

Industrial Electrification

The transition away from fossil fuels in heavy industry will not happen overnight. Yet innovations like this suggest that the technical barriers are falling faster than many expected. By retaining familiar furnace architectures while replacing the combustion core, the KIER approach lowers risk and accelerates adoption.

For steelmakers weighing investment decisions in an uncertain regulatory landscape, electrified heat treatment offers a rare combination of compliance, cost efficiency, and future readiness. As pilot projects scale into full production, the industry may find that the path to low carbon steel is less disruptive, and more achievable, than once feared.