Rewriting the Rules of Polymer Sequence Control

Polymer sequence control has long been one of the most stubborn challenges in materials chemistry. While polymer science underpins everything from construction composites and coatings to electronics and biomedical devices, the reality is that most commercial polymers are still produced with only limited control over their internal sequence. Chain length and average composition can usually be managed, but the precise order in which monomers are arranged along the backbone often remains frustratingly elusive.

That limitation matters. The sequence of monomers within a polymer chain governs how the material behaves, how it folds, how it interacts with its environment, and how it responds to heat, stress, or chemical stimuli. In effect, polymer sequences act like molecular instructions. Without reliable control over those instructions, tailoring materials for highly specialised applications becomes an exercise in compromise rather than precision engineering.

Why Traditional Polymerisation Falls Short

Conventional polymerisation strategies tend to rely on statistical processes. Monomers react according to their inherent reactivity, often competing with one another in ways that are difficult to predict or regulate once the reaction is underway. Even advanced living or controlled polymerisation techniques struggle when multiple monomer species are involved, particularly when those monomers differ significantly in structure or reactivity.

As a result, many high performance materials are engineered around what is achievable, not what is theoretically optimal. For industries such as electronics, nanomedicine, and data storage, that constraint increasingly looks like a bottleneck. These sectors demand materials whose properties are programmed at the molecular level, not averaged out across a random distribution.

A Dual Catalytic Breakthrough

A recent study published in Precision Chemistry offers a compelling route beyond those limitations. Led by researchers from Northwestern Polytechnical University in China and Monash University in Australia, the work introduces a dual catalytic system capable of delivering an unprecedented level of control over polymer sequence architecture.

At the heart of the research is a carefully engineered pairing of catalysts, PPNOAc and salenAl(III)Cl. Rather than acting independently, these catalysts operate dynamically, allowing the reaction pathway to be tuned in real time. This approach represents a significant shift away from static catalyst design towards adaptive catalytic precision engineering.

Engineering Sequence with Dynamic Control

The research team demonstrated that by adjusting the stoichiometric balance between the two catalysts, they could actively influence how monomers were incorporated into the growing polymer chain. This capability enabled the deliberate formation of gradient, statistical, and inverse gradient sequences within the same chemical system.

Such control had previously been regarded as impractical for complex terpolymerisation reactions. Yet the team successfully applied their system to a challenging combination of epoxides, aziridines, and phthalic thioanhydride. Each of these monomers brings distinct chemical behaviour, making sequence regulation particularly demanding.

By carefully managing reactivity ratios, the researchers showed that sequence distribution could be shaped rather than left to chance. In practical terms, this means polymer chains can now be designed with zones of functionality, stiffness, or responsiveness placed exactly where they are needed.

Terpolymerisation with Purpose

The successful terpolymerisation of epoxides, aziridines, and phthalic thioanhydride stands out as one of the most technically impressive aspects of the study. Terpolymer systems are notoriously difficult to control due to competing reaction pathways and uneven monomer consumption.

Through dynamic catalyst manipulation, the researchers were able to guide these reactions with a level of finesse rarely seen in polymer chemistry. The resulting materials exhibited distinct microstructures depending on catalyst ratios, confirming that sequence architecture was being actively programmed rather than passively formed.

Tuning Properties Through Catalyst Design

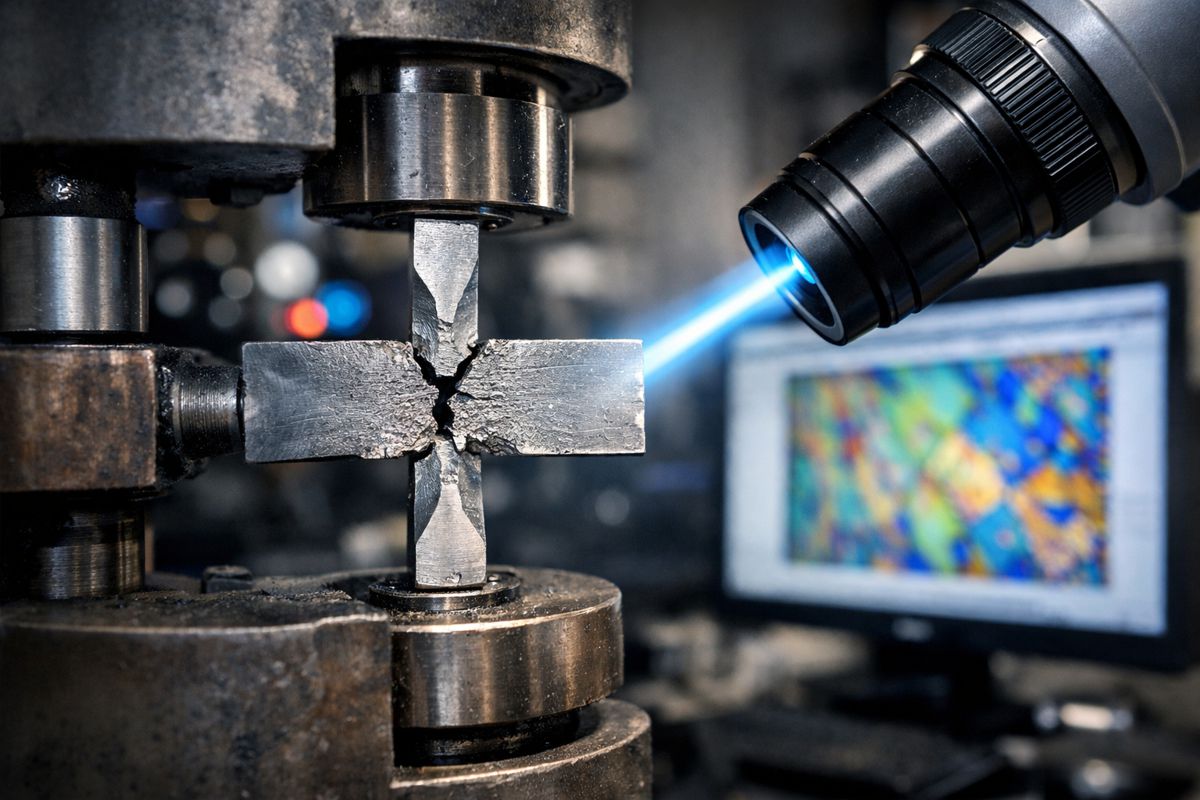

Beyond sequence control, the study also explored how different catalyst combinations influenced material performance. Thermal behaviour, structural integrity, and overall polymer stability were shown to respond directly to changes in catalytic composition.

This finding is particularly relevant for industrial applications. Construction materials, protective coatings, and high performance plastics often operate under demanding thermal and mechanical conditions. The ability to fine tune these properties during synthesis, rather than through additives or post processing, could simplify manufacturing while improving consistency and performance.

Digital Precision at the Molecular Scale

The authors were clear about the broader significance of their findings. As noted in the paper: “This new method provides a robust platform for engineers and material scientists to design polymers with digital precision, offering tailored properties that can be leveraged in advanced technologies like adaptive materials and intelligent systems. The ability to precisely control polymer sequences will undoubtedly enhance the functionalization of synthetic polymers in multiple fields.”

This concept of digital precision is particularly striking. Much like binary code underpins modern computing, controlled polymer sequences open the door to materials whose behaviour is encoded at the molecular level. That analogy is not merely poetic. Sequence controlled polymers are already being explored as candidates for molecular data storage and programmable matter.

Implications for Biomedical and Smart Materials

The implications extend well beyond the laboratory. In biomedical engineering, materials that interact predictably with biological systems are essential. Controlled polymer sequences could enable implants, drug delivery systems, and tissue scaffolds that respond precisely to physiological conditions.

Smart materials are another obvious beneficiary. Polymers designed with responsive segments arranged in defined sequences could adapt to changes in temperature, pH, or mechanical stress. Such behaviour is highly attractive for sensors, actuators, and adaptive infrastructure components where materials are expected to do more than simply endure.

Supporting Trends in Advanced Manufacturing

This work also aligns with broader trends in advanced manufacturing and materials science. Digital design, additive manufacturing, and computational materials modelling are all pushing towards greater predictability and repeatability at smaller scales.

Sequence controlled polymerisation fits neatly into that trajectory. When combined with simulation tools and machine learning driven materials discovery, dynamic catalytic systems could significantly shorten development cycles for new materials. Instead of trial and error, engineers could design polymers from first principles, confident that synthesis will deliver the intended structure.

Environmental and Sustainability Considerations

While the study focuses primarily on precision and performance, its implications for sustainability should not be overlooked. More precise materials often mean less waste, longer service life, and improved recyclability. Polymers designed with controlled degradation pathways or selective functionality could play a role in addressing long standing environmental challenges associated with plastics.

Moreover, catalytic efficiency and selectivity are central to greener chemistry. Systems that minimise side reactions and maximise monomer utilisation contribute directly to lower energy consumption and reduced chemical waste.

Expanding the Research Horizon

Despite its promise, the authors acknowledge that further research is needed. Expanding the range of compatible monomers, improving scalability, and refining catalyst stability under industrial conditions will all be essential steps before widespread adoption.

There is also scope to integrate this approach with other catalytic platforms and polymerisation techniques. Doing so could unlock even more sophisticated sequence architectures, pushing polymer science closer to the level of control long enjoyed in biological macromolecules.

Programming the Materials of Tomorrow

What this research ultimately demonstrates is a shift in mindset. Polymers are no longer just materials to be synthesised. They are systems to be programmed. By embracing dynamic catalyst design and sequence control, materials scientists are beginning to write molecular instructions with a clarity that once seemed unattainable.

For industries ranging from construction and infrastructure to electronics and medicine, that capability represents more than an incremental improvement. It signals a new era in which material performance is not merely optimised, but deliberately engineered from the ground up.