Designing Safer Access at Height for Modern Construction

Working at height remains one of the most persistent risk factors across global construction, infrastructure maintenance, logistics, and industrial operations. Despite decades of regulatory reform and advances in machine design, falls and entrapment incidents continue to feature prominently in safety statistics from Europe to North America and beyond. Against this backdrop, access equipment manufacturers are under increasing pressure to deliver platforms that not only meet regulatory requirements, but actively reduce risk through thoughtful engineering and operational simplicity.

Within this environment, Skyjack occupies a pragmatic position. Rather than chasing headline-grabbing automation or complex digital overlays, the company has focused on engineering clarity, mechanical reliability, and layered safety systems that reflect how machines are actually used on site. The result is a safety philosophy rooted in prevention, ergonomics, and jobsite realism rather than theoretical compliance.

This matters because construction safety has entered a more nuanced phase. Regulators, contractors, insurers, and policymakers increasingly recognise that safer outcomes depend not just on rules, but on how equipment design interacts with human behaviour. Machines that are intuitive, predictable, and easy to maintain are less likely to be misused, bypassed, or poorly serviced. In that sense, access equipment safety is no longer just an operational issue, it is an infrastructure resilience concern with commercial and legal consequences.

Guardrails First and Why Passive Safety Still Matters

At the core of Skyjack’s approach to fall protection is a deliberate emphasis on passive safety. On its access platforms, the primary fall protection system is the guardrail itself. This design choice aligns with global safety hierarchies that prioritise collective protection over personal protective measures wherever possible. A properly designed guardrail system does not rely on operator action, training refreshers, or situational judgement. It simply works, shift after shift.

This philosophy is particularly relevant in high-turnover labour environments or multi-contractor sites where consistency of training can be uneven. While Personal Fall Protection Equipment may still be required under local regulations, Skyjack’s baseline design assumes that the safest system is the one that does not depend on perfect human behaviour. Where PFPE is used, platforms are fitted with dedicated lanyard attachment points designed to integrate cleanly with compliant equipment.

This layered approach reflects a broader industry shift away from treating PPE as a silver bullet. Research from international safety bodies has consistently shown that reliance on personal equipment alone increases exposure to misuse, fatigue, and procedural drift. Guardrails, by contrast, remove an entire category of decision-making from the moment-to-moment pressures of the jobsite.

Secondary Guarding and the Reality of Entrapment Risk

Entrapment remains one of the most serious hazards associated with mobile elevating work platforms, particularly in confined or overhead environments. In response, Skyjack has standardised its electrical secondary guarding system across all boom lifts. The system uses a sensor bar that instantly stops machine functions if pressure is detected, while simultaneously activating an audible siren and a high-intensity flashing beacon.

The significance of this design lies in its immediacy. By cutting motion at the point of contact rather than relying on operator reaction time, the system reduces the severity of incidents caused by inadvertent control activation. Importantly, the alert signals also draw attention from nearby workers, supervisors, or spotters, increasing the chances of rapid intervention.

This kind of secondary guarding reflects lessons learned across the wider access equipment sector. Industry reviews following serious incidents have highlighted that entrapment often occurs not through reckless behaviour, but through momentary loss of spatial awareness or unexpected machine response. Engineering controls that assume human fallibility, rather than ideal behaviour, are increasingly seen as essential rather than optional.

Rethinking Scissor Lift Operation Through Ergonomics

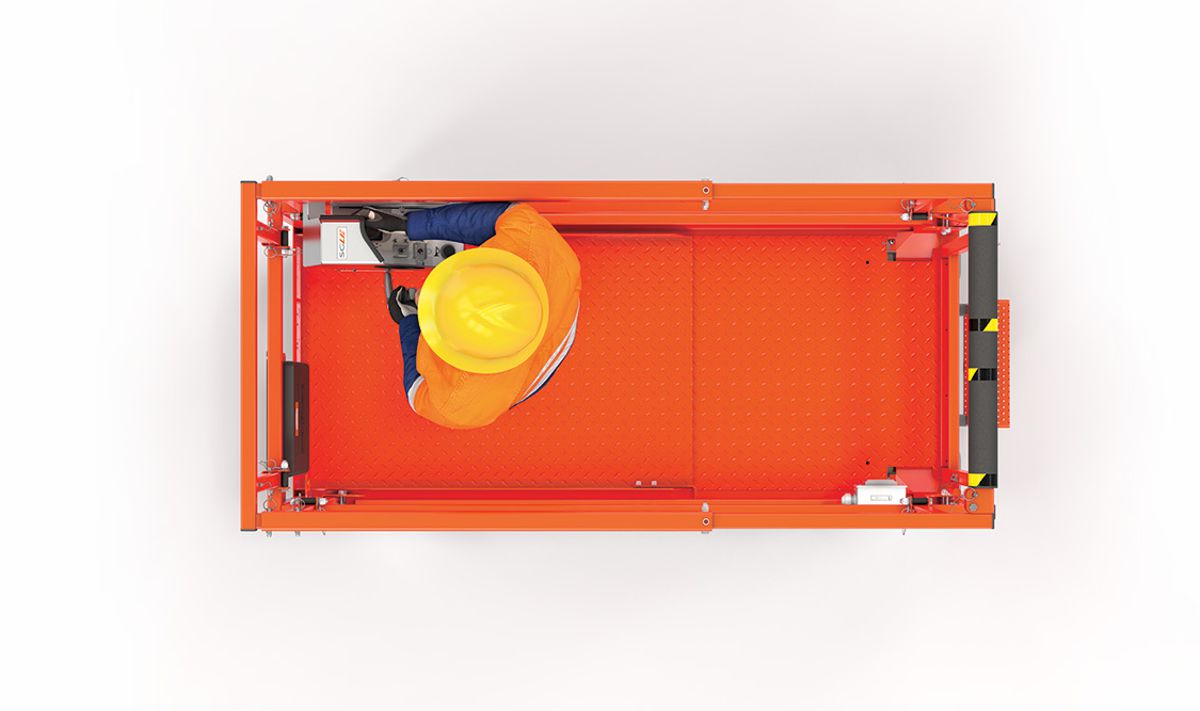

While boom lifts present one set of risks, scissor lifts introduce a different profile, particularly around vertical movement and proximity to overhead structures. Skyjack’s Secondary Guarding Lift Enable system addresses this by requiring two deliberate actions to raise the platform: activation of the joystick and a tamper-proof secondary enable.

This dual-input requirement ensures that lifting cannot occur accidentally, while the physical placement of controls encourages an upright operator posture. By keeping the operator’s body away from the guardrails during lifting, the system mitigates one of the most common precursors to entrapment incidents. If either control is released, movement stops immediately.

Crucially, Skyjack has avoided over-engineering the system. Lowering and driving functions remain joystick-only, preserving operational efficiency and reducing frustration that can lead to unsafe workarounds. This balance between protection and practicality is significant. Overly complex safety systems, however well intentioned, often fail in real-world conditions when operators seek to bypass them to maintain productivity.

No Single Answer and the Role of Risk Assessment

One of the more notable aspects of Skyjack’s safety strategy is its explicit acknowledgement that no single solution fits every jobsite. Entrapment risks vary widely depending on task, environment, operator experience, and site layout. As a result, the company positions its secondary guarding systems as part of a broader risk-based approach rather than a universal fix.

This perspective aligns with evolving regulatory guidance that places greater emphasis on site-specific risk assessments. Rather than mandating identical controls across all applications, regulators are increasingly encouraging duty holders to select appropriate measures based on documented hazards. Equipment that offers adaptable safety options supports this more mature, responsibility-driven model.

From a commercial standpoint, this flexibility also matters. Contractors operating across multiple jurisdictions face differing regulatory interpretations and enforcement priorities. Equipment that can accommodate these variations without modification or retrofitting reduces compliance costs and procurement complexity.

Accessories That Support Safer, More Efficient Workflows

Safety does not exist in isolation from productivity. Improvised material handling on platforms remains a common source of risk, particularly when tools or components are carried in ways not intended by the machine design. Skyjack’s ACCESSORYZERS range addresses this by providing purpose-built attachments such as tool caddies, pipe racks, board carriers, and glazing kits.

These accessories are designed to integrate directly with the platform, reducing the temptation to overload guardrails or balance materials in unstable positions. By supporting safer material transport, they also reduce fatigue and improve task efficiency, a factor often overlooked in safety discussions.

From an infrastructure delivery perspective, such incremental improvements add up. Fewer dropped objects, less manual handling strain, and more orderly platforms contribute to lower incident rates and more predictable project timelines. In high-value construction environments, that predictability translates directly into reduced insurance exposure and fewer schedule disruptions.

Environmental Protection as a Safety Issue

Environmental considerations are increasingly intertwined with workplace safety, particularly on sensitive sites such as hospitals, clean manufacturing facilities, and heritage structures. Skyjack’s ECO initiatives reflect this convergence. Features such as emission-reducing start systems and spill-containment trays are positioned not as optional extras, but as part of responsible equipment deployment.

The ECOTRAY system, designed to prevent hydraulic drips from reaching floors or terrain, addresses both environmental compliance and slip hazards. In indoor or public-facing environments, this kind of containment can be as critical to safety as fall protection itself. Similarly, reduced noise and emissions contribute to healthier working conditions, particularly on long-duration projects.

As sustainability reporting becomes more tightly linked to procurement decisions, equipment that demonstrably reduces environmental risk gains strategic value. For public infrastructure clients and multinational contractors, these features increasingly support broader ESG commitments alongside traditional safety metrics.

Why Access Equipment Design Still Matters

In an era of rapid technological change, it is tempting to view safety as a problem to be solved through sensors, connectivity, or automation alone. Yet the fundamentals of access equipment safety remain grounded in mechanical integrity, ergonomic clarity, and human-centred design. Skyjack’s approach illustrates that progress does not always require complexity.

For the global construction and infrastructure ecosystem, this has wider implications. As labour shortages persist and project margins tighten, equipment that is intuitive, durable, and inherently safe reduces reliance on constant supervision and retraining. That, in turn, supports safer worksites, more resilient delivery programmes, and a lower overall risk profile for major projects.

In the end, safety at height is not just about preventing accidents. It is about designing systems that recognise how people work under pressure, in varied conditions, across diverse regulatory landscapes. Access equipment that respects those realities plays a quiet but essential role in building safer, more sustainable infrastructure worldwide.