Connectivity is Redefining Construction Delivery

Construction has always been a business of coordination. Machines, people, materials, and time must align precisely for projects to succeed. Yet even the most carefully planned programmes have long been vulnerable to delays that emerged once work began. Poor visibility, idle assets, and fragmented communication continued to undermine delivery performance across the sector.

When we spoke with Benedict Aicher, Vice President of Strategy and Transformation at Trackunit, he was clear that this reality was no longer being accepted as inevitable. Connectivity, he explained, had moved decisively from optional enhancement to operational necessity.

At the core of the issue, Aicher said, was execution rather than ambition. “Ask any contractor what keeps them up at night, and it’s not just winning bids; it’s delivering them.” In an industry where every lost hour directly affected margins, predictability had become a defining competitive advantage.

The Cost of Disconnection Had Become Impossible to Ignore

The construction sector had long absorbed inefficiency as part of the job. Delays were often treated as unavoidable side effects of complexity, weather, and scale. However, Aicher pointed out that the financial consequences of that mindset were now well understood.

“Every lost hour is money wasted, and the evidence is clear,” he said, referring to industry research indicating that “the lack of connectivity costs the construction industry more than $177 billion annually.” That loss, he noted, was rarely confined to a single line item. It surfaced across schedules, budgets, and reputations, gradually eroding trust between contractors and clients.

What stood out in the discussion was not simply the size of the loss, but the industry’s changing response to it. Aicher observed that “what’s changed is that the industry is no longer resigned to this.” Connectivity, once viewed as a luxury or an experiment, was now being used as a tool for control.

From Assumption to Visibility on the Jobsite

For much of its history, construction had relied heavily on experience and instinct. Radio calls, site walks, and retrospective reporting shaped decisions. While that approach produced resilient professionals, it also created blind spots.

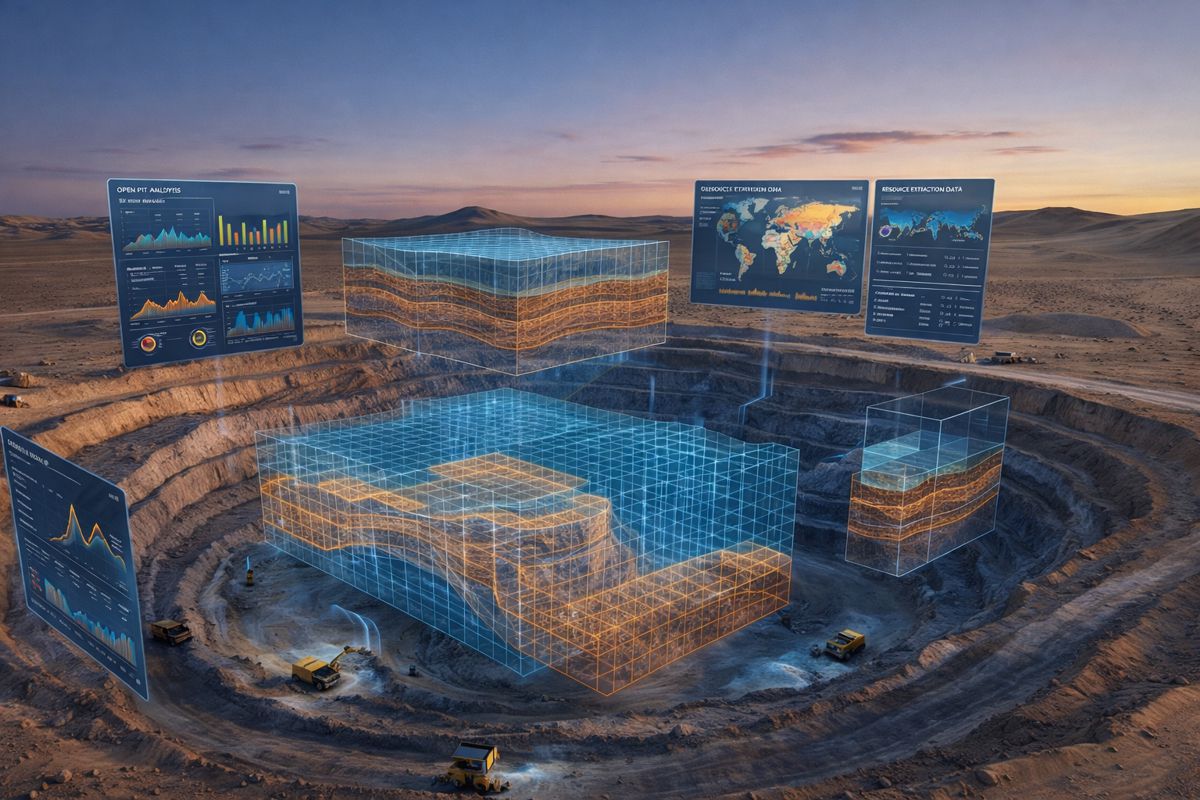

Aicher explained that connectivity was replacing assumption with evidence. “Connectivity has become a tool for control, offering visibility, coordination, and data-driven decision-making that once felt out of reach.” While some firms still relied on instinct and fragmented communication, others were building “connected ecosystems where every asset, operator, and process contributes to a single real-time picture.”

The impact of that shift was already visible. “The result?” he said. “Projects that stay on schedule, equipment that earns its keep, and teams that work smarter, not harder.”

Equipment Utilisation Came Into Sharp Focus

Few inefficiencies had proven as persistent as underutilised equipment. Heavy machinery represented one of the largest capital investments contractors made, yet much of it sat idle for significant portions of its working life.

Aicher described the scale of the issue plainly. “Traditionally, machines spend 30–40% of their working life idle, capital sitting still.” In disconnected environments, that idle time often went unseen or unchallenged.

Connected fleets, he explained, fundamentally changed that dynamic. “Connected fleets allow contractors to monitor usage, fuel burn, and idle time in real time.” When that visibility extended across multiple sites, decision-making accelerated. “When one site has excess assets and another is short, redeployment can happen within hours instead of weeks.”

In an industry where delays compounded quickly, that responsiveness mattered.

Anticipating Risk Rather Than Reacting to It

Connectivity, Aicher said, did more than optimise assets. It altered how contractors managed risk. Construction projects were shaped by variables ranging from subcontractor coordination to weather-sensitive operations, many of which historically became visible only after disruption occurred.

Connected platforms changed the timing of those insights. “Connected platforms pull data from multiple sources, allowing project managers to spot risks before they become delays,” he explained. Instead of discovering issues after the fact, “teams can reallocate resources in the moment.”

This represented a fundamental shift in decision-making. “In the past, this level of insight depended on instinct,” Aicher said. “Today, it’s a matter of intelligence.”

Collaboration Became Systematic, Not Accidental

Many construction delays, Aicher noted, did not stem from lack of effort, but from slow or incomplete information flow. He described disconnected jobsites as environments full of blind spots, including “crews waiting on instructions, materials arriving early or late, equipment down for maintenance without anyone knowing.”

Connectivity helped institutionalise collaboration. “Shared real-time dashboards give every stakeholder, from field teams to the office, the same version of the situation,” he said. With tasks assigned and progress visible, “communication stays in context.”

The leadership dynamic shifted as a result. “Instead of managing chaos, leaders can orchestrate performance.” Over time, this shared visibility influenced culture as well as workflow. “When teams have clarity, accountability follows naturally.” The traditional divide between site and office began to fade.

Predictive Maintenance Quietly Changed the Economics

Unexpected equipment failure remained one of the most disruptive forces in construction. Connectivity reframed maintenance from reactive repair to predictive discipline.

Aicher explained that “connectivity turns maintenance into a predictive discipline.” By “analysing hours of operation, load, vibration, and temperature,” contractors could “anticipate service needs, avoiding breakdowns altogether.”

Predictive maintenance rarely attracted attention, but its impact was significant. “It prevents costly repairs, keeps machines running, and protects schedules.” Over time, the data also supported longer-term decision-making. “Data also informs smarter procurement decisions, revealing which brands, models, and configurations deliver the best performance and ROI.”

Data Evolved Into a Strategic Asset

Every connected operation generated large volumes of data. The differentiator, Aicher stressed, was not access but interpretation.

“The contractors who interpret and act on that data are pulling ahead,” he said. Analytics exposed inefficiencies ranging from “excessive idling” to “overlapping rentals” and “recurring patterns in delays.”

For leading contractors, operational data had become a strategic asset. “Truly data-driven contractors will base decisions on evidence rather than gut feeling.” The competitive implications were clear. “The question is no longer whether this shift will happen,” Aicher said, “it’s who will still be competitive once it’s complete.”

A Human Industry, Enabled by Technology

Despite the growing role of digital tools, Aicher emphasised that construction remained a human industry.

“Connectivity empowers people,” he said. “For supervisors, it reduces firefighting. For operators, it reduces downtime and improves safety. For executives, it creates confidence in delivery commitments.”

However, he cautioned that technology alone was not enough. “Adopting connectivity requires more than systems; it requires belief.” Trust remained critical. “Technology succeeds only when people trust it.” That was why the most successful contractors invested as much in training and culture as they did in software.

The Industry Reached a Tipping Point

Construction had always been about alignment. Connectivity did not change that principle. It strengthened it.

“Construction has always been about coordinating people, machines, and time,” Aicher said. Connectivity “doesn’t replace hard hats; it augments the systems that support them.”

The industry, he argued, had reached a decisive moment. “Operating without connected equipment, real-time data, or shared visibility no longer just puts you behind schedule; it puts you behind the industry.” Contractors waiting for the perfect moment to digitise were unlikely to find it.

As Aicher concluded, “connectivity isn’t just a tool for better construction; it has become the foundation of competitiveness.”