The Growing Role of Additive Manufacturing in Modern Industry

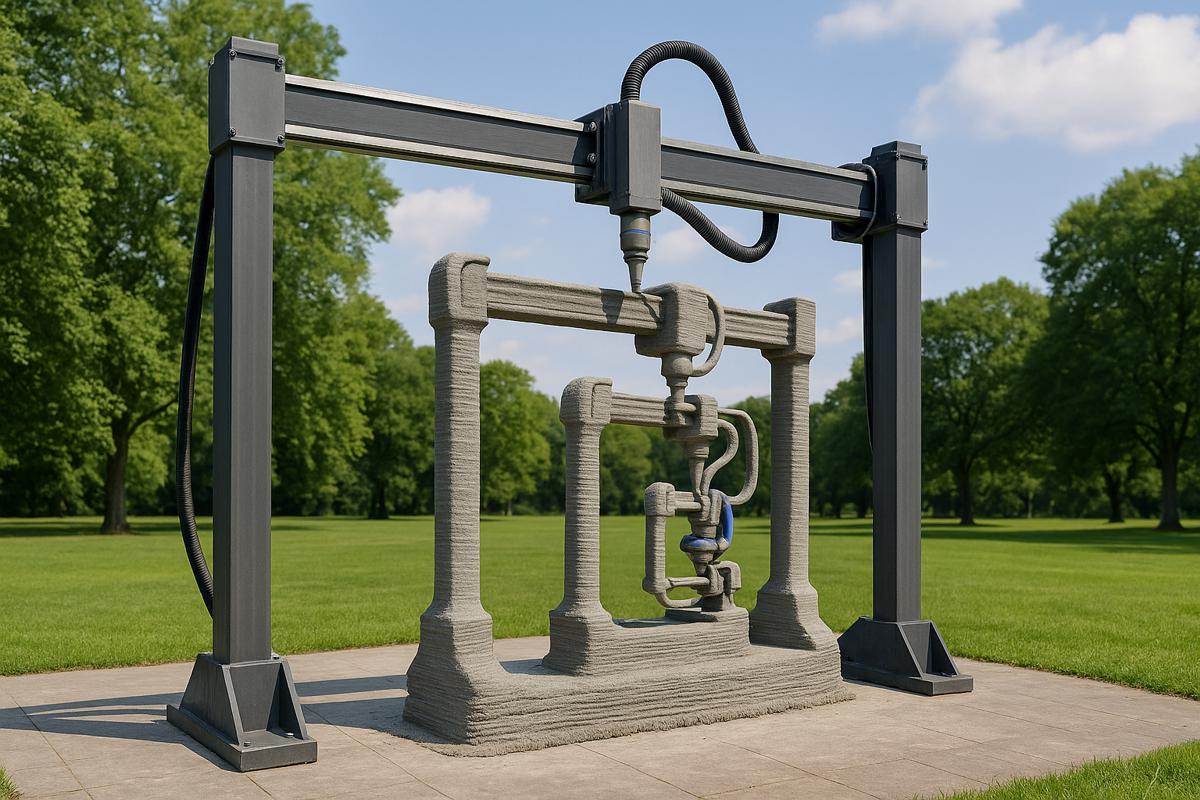

Additive manufacturing, often called 3D printing, is no longer just a tool for making quick models. Today, it plays a major role in how products are designed, tested, and produced across many industries.

From healthcare and automotive to construction and consumer goods, companies are using this technology to move faster, cut waste, and create parts that were once hard or even impossible to make. As businesses look for smarter and more flexible ways to build products, additive manufacturing is becoming a key part of modern production.

This shift is changing not only how things are made, but how industries think about design, speed, and innovation.

Additive manufacturing in industry: the 2026 reality check (beyond the hype cycle)

Look, we’ve all heard the oversized promises. To figure out where additive manufacturing actually earns its keep today, you’ve got to slice through a decade of hype and shelved pilot programs—so let’s talk about what’s genuinely working on real factory floors.

Industrial 3D printing hardware sales jumped 5% year-over-year in Q3 2025, pushed forward by healthy shipments of starter-tier printers and a noticeable uptick in metal platform sales. That bump? It’s not vapor. Manufacturers are investing in capacity because the business case finally pencils out.

Additive manufacturing applications shifting from lab to line

Once you’ve zeroed in on the right applications, your real challenge becomes transitioning from proof-of-concept validation to bulletproof production—a leap that demands process discipline and qualification rigor most companies underestimate.

Common production anchors? Jigs, fixtures, end-of-arm tooling, and short-batch end-use components. Service parts and digital warehousing aren’t far behind. What started as innovation theatre now plugs directly into shop-floor quality systems, MES tracking, and inspection routines. In fast-cycle industries, plenty of manufacturers lean on 3d printing Services to access qualified production capacity, specialized material libraries, or certification documentation, particularly when their internal operations haven’t scaled yet or when compliance requirements demand externally validated processes.

Additive manufacturing vs traditional methods: the decision matrix manufacturers actually use

Figuring out where AM outperforms legacy processes is only part of your puzzle; the smart operators deploy a decision framework to nail down when to pick additives over the old guard. CNC machining gives you tight tolerances and beautiful surface finishes, sure—but it chews through material like crazy and demands lengthy setup for anything geometrically interesting. Injection moulding crushes high-volume runs but chains you to pricey tooling that can’t pivot when your design inevitably changes.

Additive manufacturing applications dominate when complexity costs you nothing extra, when you need rapid iteration without retooling nightmares, or when customization can’t wait for volume thresholds. Here’s a quick mental filter: high geometric complexity, constant design tweaks, unpredictable demand, and opportunities to consolidate parts all tilt toward AM. Tight tolerance demands, mirror finishes, and production runs north of 10,000 units? Traditional methods still own that territory.

Industrial 3D printing technologies powering modern manufacturing (process-by-process guide)

Now that you’ve mapped out where additive manufacturing fits your operation, let’s dig into how different technology stacks deliver on those promises—because betting on the wrong process is your fastest route to a failed program.

Polymer industrial 3D printing for production-grade parts

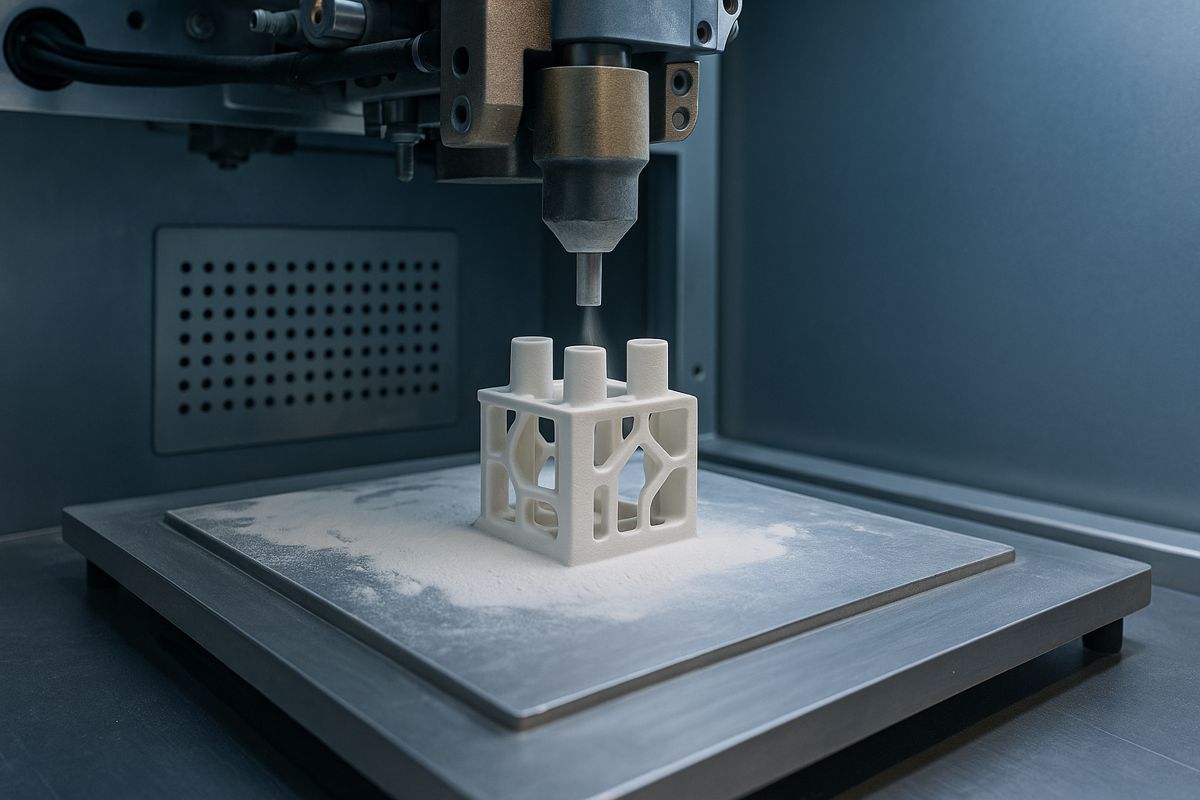

FDM constructs rugged thermoplastic parts with impressive build volumes, perfect for guards, enclosures, and production fixtures. SLS cranks out tough nylon components without support structures, enabling efficient batch production for functional prototypes and limited runs.

SLA produces fine-detail parts ideal for casting patterns, moulds, and medical/dental work. MJF and similar powder-bed systems target repeatability at higher volumes, delivering production-run consistency with controlled dimensional accuracy.

Emerging methods manufacturers are adopting now

Beyond mature powder-bed platforms, forward-thinking manufacturers are already deploying next-gen methods their competitors haven’t evaluated yet—building early advantages in repair operations, micro-scale components, and multi-material assemblies.

Cold spray AM addresses repair applications and coating-style builds. Micro-AM targets electronics assemblies, microfluidic devices, and ultra-precise components. Multi-material and embedded systems weave in conductive traces and embedded sensors when applications demand them.

3D printing in manufacturing: high-impact use cases across modern industry

With technology-material pairings mapped, let’s connect them to specific deployments where manufacturers are documenting genuine returns—frequently within their first production quarter.

Tooling, jigs, fixtures, and end-of-arm tooling (fast ROI category)

While faster prototyping grabs the spotlight, your highest ROI usually lives in unsexy factory-floor tooling—where payback timelines get measured in weeks instead of years. Typical returns show up through reduced downtime, ergonomic wins, and repeatability improvements.

Think drill guides, inspection fixtures, welding jigs, and EOAT you can print on-demand and tune per production batch.

End-use production parts in additive manufacturing in industry

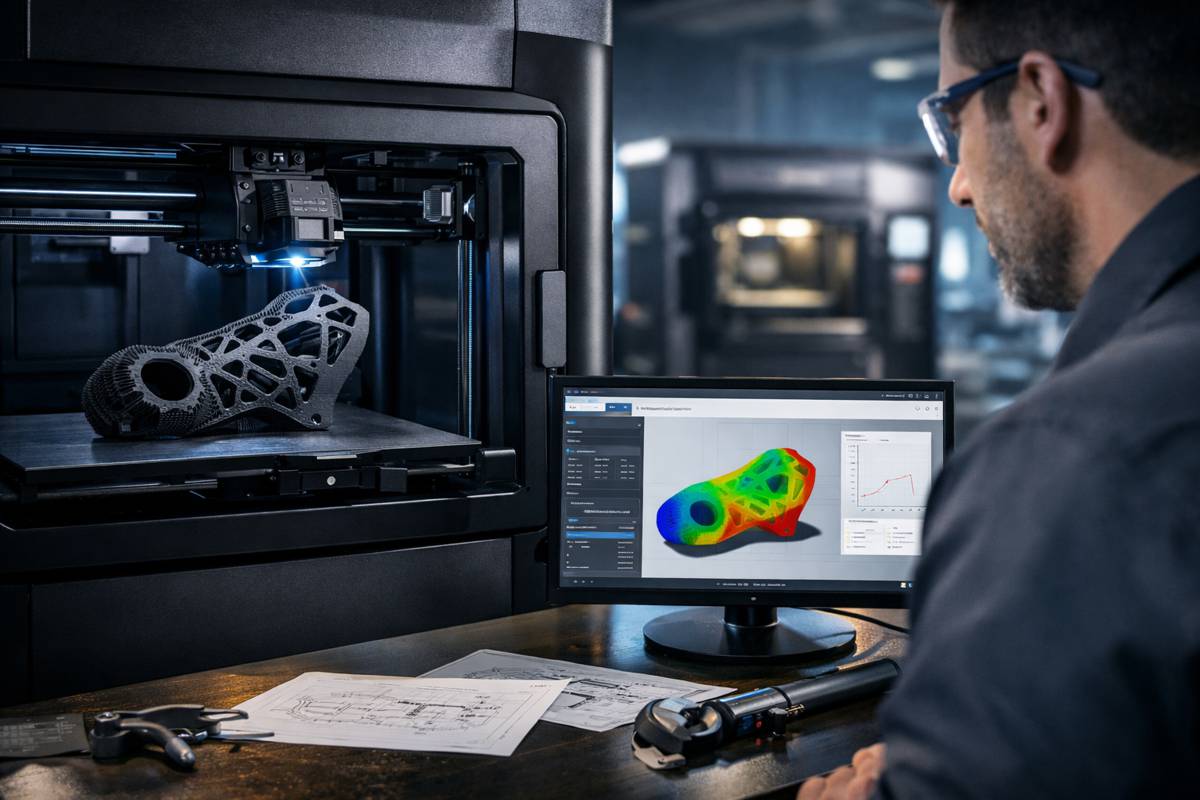

After tooling applications validate your AM capabilities and culture, end-use production parts become your logical next expansion—targeting specific geometries and volume ranges where the math works. Ideal candidates feature low-to-mid volumes, complex shapes, high product mix, and customisation requirements.

Part consolidation, weight savings, lattice structures, and internal cooling channels unlock performance advantages impossible through conventional manufacturing.

Economics of additive manufacturing in industry: cost-per-part drivers and ROI levers

Achieving favourable part economics on spreadsheets means absolutely nothing if your operation can’t consistently deliver quality at the throughput your schedule demands—which is exactly where workflow integration separates pilots from production programs.

Cost structure breakdown for industrial 3D printing

Material spend, machine hours, labour, post-processing, inspection, and scrap rates accumulate fast. Hidden expenses include powder management, environmental health and safety protocols, training investments, and facility upgrades that never appear on equipment sales quotes.

Proven ROI levers manufacturers use to win with additive manufacturing

Part consolidation, tooling elimination, compressed lead times, minimized downtime, and inventory reduction all generate measurable financial returns. Standardizing design patterns and print parameters cuts validation overhead and accelerates scaling.

Common Questions About Industrial Additive Manufacturing

When does additive manufacturing beat injection moulding on cost in real production?

Break-even volumes typically land somewhere between 500 and 10,000 units, driven by part complexity, tooling investment, and material specs. Complex geometries push that threshold significantly lower.

Which 3D printing in manufacturing technology is best for end-use parts: SLS, MJF, FDM, or SLA?

SLS and MJF consistently deliver superior mechanical properties and throughput for functional components. FDM handles larger, less-critical parts effectively. SLA excels in aesthetic and detail-critical applications.

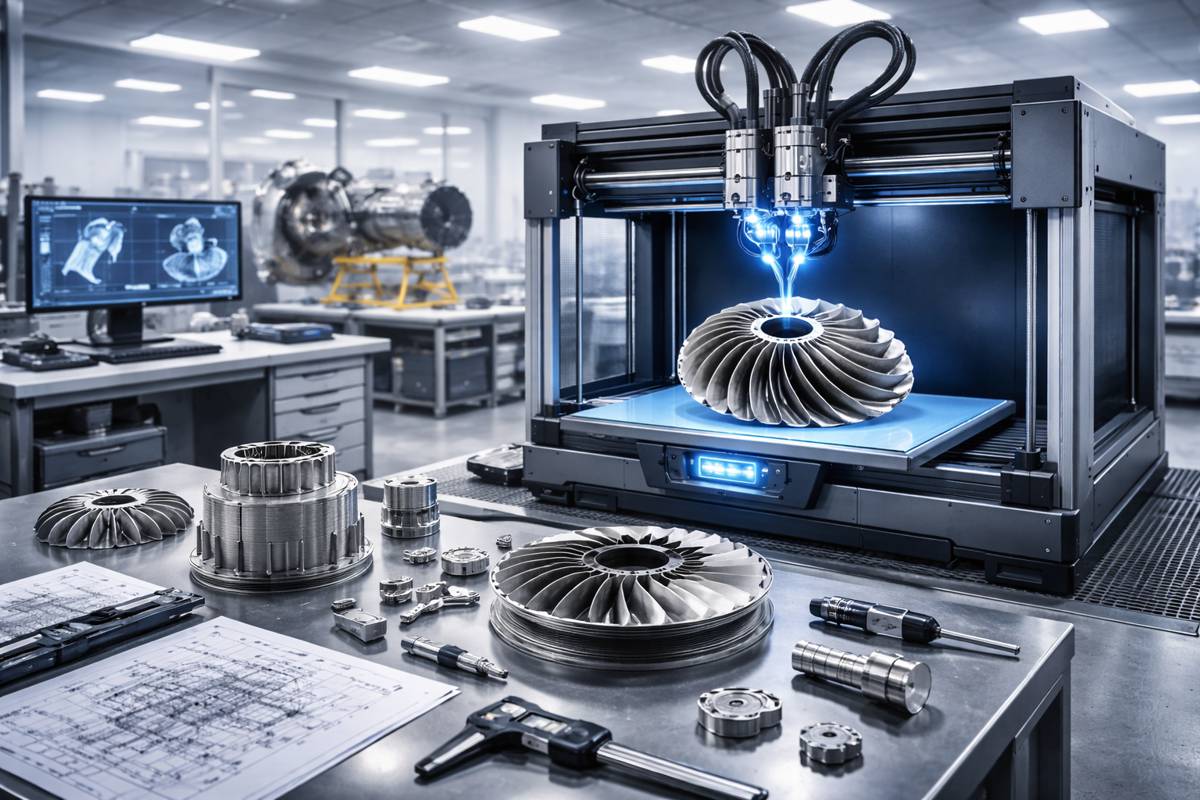

Which industries are adopting additive manufacturing in industry the fastest in 2026?

Aerospace, defence, medical devices, dental, automotive tooling, and industrial equipment manufacturers lead adoption curves. The energy sector and electronics follow closely with repair and custom component deployments.

Final Thoughts on Industrial Additive Manufacturing’s Real Value

Additive manufacturing has graduated from hype-cycle darling to factory-floor workhorse, generating documented wins in tooling, production components, and digital inventory strategies.

Success hinges on honest application selection, methodical implementation, and rigorous ROI measurement—not enthusiasm alone. The manufacturers winning right now treat AM as a strategic complement to traditional methods rather than a wholesale replacement, and they construct capabilities incrementally instead of chasing overnight transformation.

If you’re prepared to cut through the noise and capture tangible value, the proven roadmap already exists.