Asphalt & Bitumen Month

As one of the cornerstones of modern infrastructure, asphalt and bitumen form the backbone of our highways, city streets, and airport runways. This month takes a deep dive into the technologies, materials, and methods that are shaping the future of pavements worldwide. From the evolution of asphalt plants and advanced mixing processes to the chemistry of bitumen additives and the integration of recycled materials, June will explore how the industry is tackling today’s biggest challenges: decarbonisation, durability, and cost efficiency.

With global road networks under pressure from climate change, increased traffic volumes, and rising sustainability targets, innovation in pavements has never been more critical. Case studies will highlight pioneering projects using warm mix technologies, polymer-modified binders, and circular approaches such as reclaimed asphalt pavement (RAP), while expert voices will provide insights on performance specifications, digital plant controls, and whole-life asset management.

By bringing together cutting-edge research and practical field experience, Asphalt, Bitumen & Pavements Month will showcase how resilient, sustainable road surfaces are being built to meet the demands of the future.

Trends in the Asphalt and Bitumen Industry

The asphalt and bitumen industry is experiencing significant advancements and shifts, driven by the need for sustainability, technological innovation, and improved performance.

As infrastructure demands grow globally, the industry is responding with cutting-edge solutions that not only enhance the quality and durability of roads but also address environmental concerns. Here, we explore the top trends shaping the future of asphalt and bitumen.

Sustainability and Environmental Impact

- Recycled Materials: Increased use of recycled asphalt pavement (RAP) and reclaimed asphalt shingles (RAS) to reduce waste and lower the carbon footprint of road construction.

- Warm Mix Asphalt (WMA): Adoption of WMA technologies that reduce production temperatures, resulting in lower energy consumption and emissions.

- Bio-based Binders: Development of bio-based and renewable binders as alternatives to traditional bitumen, aiming to reduce dependency on fossil fuels.

Technological Advancements

- Smart Roads: Integration of sensors and IoT technology into asphalt pavements to monitor road conditions, traffic flow, and maintenance needs in real-time.

- Advanced Machinery: Use of state-of-the-art equipment like automated pavers and rollers for improved efficiency and precision in asphalt laying and compaction.

- 3D Printing: Exploration of 3D printing technology for creating custom asphalt mixes and designs, enhancing the versatility of road construction.

Performance Enhancement

- Polymer-Modified Bitumen (PMB): Increasing use of PMB to enhance the durability, flexibility, and weather resistance of asphalt pavements.

- Nanotechnology: Application of nanomaterials to improve the mechanical properties, longevity, and overall performance of bitumen and asphalt.

Cost Efficiency

- Optimized Mix Designs: Development of new mix designs that balance cost, performance, and sustainability, helping to reduce project expenses while maintaining quality.

- Lifecycle Cost Analysis: Emphasis on lifecycle cost analysis to evaluate the long-term economic benefits of different asphalt formulations and construction methods.

Regulatory Changes

- Stricter Environmental Regulations: Compliance with increasingly stringent environmental regulations driving the adoption of greener technologies and practices in the industry.

- Standardization and Quality Control: Efforts to standardize materials and processes to ensure consistent quality and performance across different projects and regions.

Global Infrastructure Development

- Urbanization: Rapid urbanization and the need for modern infrastructure in developing countries are driving demand for advanced asphalt and bitumen solutions.

- Maintenance and Rehabilitation: Growing focus on the maintenance and rehabilitation of existing road networks to extend their lifespan and improve safety.

Innovative Applications

- Porous Asphalt: Use of porous asphalt for improved stormwater management and reduced surface runoff in urban areas.

- Coloured Asphalt: Implementation of coloured asphalt for aesthetic purposes, traffic management, and enhanced visibility in certain areas.

As the asphalt and bitumen industry continues to evolve, these trends highlight the sector’s commitment to advancing technology, sustainability, and efficiency. By staying abreast of these developments, industry professionals can ensure they are well-equipped to meet the demands of modern infrastructure projects and contribute to the creation of safer, more sustainable roads.

Leading Bitumen and Asphalt Companies

The global bitumen and asphalt industry is driven by several key players who lead in innovation, production, and distribution of these essential materials.

Here, we highlight some of the most influential companies shaping the future of bitumen and asphalt:

- Royal Dutch Shell PLC: A major player in the energy sector, Shell is renowned for its comprehensive bitumen solutions used in roads, roofing, and various industrial applications.

- Sinopec: As one of China’s largest petroleum and petrochemical enterprises, Sinopec produces a wide range of bitumen products that are essential for infrastructure projects.

- CNOOC Limited: This leading Chinese oil and gas producer plays a significant role in the bitumen market, supplying high-quality asphalt materials.

- China National Petroleum Corporation (CNPC): CNPC is a key state-owned enterprise in China, offering a diverse array of bitumen products used in road construction and maintenance.

- TOTAL S.A: A global energy giant, Total is a major supplier of bitumen, known for its innovative approaches to sustainable and high-performance asphalt solutions.

- PJSC Rosneft Oil Company: Russia’s largest oil producer, Rosneft, is a significant player in the bitumen industry, providing advanced bitumen products for various infrastructure needs.

- Hindustan Petroleum Corporation Limited (HPCL): HPCL is a leading Indian oil and gas company, offering a broad spectrum of bitumen products crucial for the country’s road network development.

- Indian Oil Corporation Ltd (IOCL): As India’s largest commercial enterprise, IOCL is a dominant force in the bitumen market, supplying high-quality asphalt to numerous infrastructure projects.

- Petro Tar Co.: This company specializes in the production and export of high-quality bitumen, catering to a global market with its extensive range of products.

- Kimya Refinery Group: Known for its innovative bitumen products, Kimya Refinery Group is a prominent name in the industry, serving both domestic and international markets.

- Wellbank Global PTE Ltd: A leading supplier of bitumen and asphalt, Wellbank Global PTE Ltd delivers top-notch materials for road construction and maintenance across various regions.

- The Bahrain Petroleum Company B.S.C. (BAPCO): BAPCO is a major player in the Middle East, providing high-quality bitumen products for infrastructure projects throughout the region.

- Saudi Bitumen Industries Co. Ltd.: A key supplier in Saudi Arabia, this company produces a wide range of bitumen products essential for the country’s extensive road network.

- Rhine Middle East LLC: Operating in the Middle East, Rhine Middle East LLC provides top-tier bitumen solutions for various construction projects.

- Regional Petroleum Products Corporation: A significant player in the bitumen industry, this corporation supplies premium asphalt materials to a broad market.

- Total Oil India Pvt Ltd: A subsidiary of Total S.A, this company offers advanced bitumen solutions tailored for the Indian infrastructure sector.

- The Bitumen Broker: Specializing in the trading and distribution of bitumen, The Bitumen Broker connects suppliers with global buyers, ensuring a steady supply of quality asphalt materials.

These companies are at the forefront of the bitumen and asphalt industry, driving innovation and ensuring the supply of essential materials for infrastructure projects worldwide.

Leading Resources for the Asphalt and Bitumen Industry

The asphalt and bitumen industry is rich with resources that provide valuable information, insights, and tools for professionals in the field. Here are the top resources that industry experts and stakeholders can rely on for the latest developments, best practices, and technical guidance:

1. National Asphalt Pavement Association (NAPA)

NAPA provides extensive resources including research reports, technical publications, webinars, and industry news to support asphalt pavement professionals.

2. Asphalt Institute

The Asphalt Institute offers a wealth of technical manuals, training programs, and research studies focused on improving the quality and performance of asphalt pavements.

3. International Bitumen Emulsion Federation (IBEF)

IBEF is dedicated to promoting the use of bitumen emulsions and provides technical documents, conference proceedings, and industry standards.

4. Transportation Research Board (TRB)

TRB offers a comprehensive collection of research papers, reports, and publications on various aspects of transportation infrastructure, including asphalt and bitumen.

5. European Asphalt Pavement Association (EAPA)

EAPA provides a range of resources including technical guidelines, position papers, and industry updates relevant to the European asphalt pavement industry.

6. Federal Highway Administration (FHWA)

The FHWA offers technical publications, research findings, and best practice guides to support the construction and maintenance of asphalt pavements in the United States.

7. Institute of Asphalt Technology (IAT)

IAT provides professional development opportunities, technical publications, and a journal focused on advancements in asphalt technology.

8. International Society for Asphalt Pavements (ISAP)

ISAP promotes international cooperation and provides access to conference proceedings, research papers, and industry standards.

9. Transport Research Laboratory (TRL)

The TRL is a global centre for innovation in transport and mobility, offering research, consultancy, and industry software solutions to improve transport infrastructure and sustainability.

10. Asphalt UK

Asphalt UK provides comprehensive information on asphalt usage in the UK, including technical guidance, best practices, industry news, and updates on regulations and standards.

11. Association of Asphalt Paving Technologists (AAPT)

AAPT promotes the advancement of asphalt paving technology through technical publications, annual meetings, and industry collaboration.

12. Institute of Highway Engineers (IHE)

IHE offers professional development, technical resources, and certifications for highway engineers, focusing on best practices and innovation in highway construction and maintenance.

13. Pavement Preservation & Recycling Alliance (PPRA) | RoadResource.org

PPRA provides a comprehensive platform for pavement preservation, recycling, and sustainable practices, offering technical resources, training, and best practice guidelines.

These resources are essential for staying informed about the latest trends, technologies, and best practices in the asphalt and bitumen industry. Whether you are a contractor, engineer, researcher, or policymaker, these platforms offer valuable insights and tools to enhance your knowledge and expertise.

Top Global Events for the Asphalt and Bitumen Industry

Attending industry events is crucial for professionals looking to stay up-to-date with the latest trends, technologies, and networking opportunities in the asphalt and bitumen sector.

Here are some of the top global events that industry stakeholders should consider, along with their host countries:

1. World of Asphalt

Held annually in the United States, World of Asphalt is a premier event featuring exhibits, educational sessions, and networking opportunities for professionals in the asphalt industry. This event is an excellent platform for learning about the latest innovations, equipment, and best practices in asphalt pavement construction and maintenance.

2. Asphalt Institute Annual Meeting

The Asphalt Institute Annual Meeting takes place in the United States and gathers industry leaders, researchers, and policymakers to discuss the latest advancements and challenges in the asphalt sector. Attendees can benefit from presentations, workshops, and networking opportunities that address key issues and emerging trends.

3. International Conference on Asphalt Pavements (ISAP)

Organized by the International Society for Asphalt Pavements, this conference is hosted in various international locations. It focuses on cutting-edge research, technological innovations, and global best practices in asphalt paving. The event attracts researchers, engineers, and industry professionals from around the world.

4. Eurobitume Congress

The Eurobitume Congress event is held in various European locations, brings together bitumen industry experts from across Europe to discuss regulatory developments, sustainability, and technological advancements. The Eurobitume Congress is an important gathering for professionals seeking to stay informed about the latest industry trends and standards.

5. International Bitumen Conference (IBEF)

Organized by the International Bitumen Emulsion Federation, this conference is held in various international locations and focuses on the latest developments and applications of bitumen emulsions. It provides a platform for industry professionals to share knowledge, research, and innovative practices.

6. National Asphalt Pavement Association (NAPA) Annual Meeting

Taking place in the United States, the annual National Asphalt Pavement Association meeting features presentations, workshops, and networking opportunities for professionals in the asphalt pavement industry. NAPA’s event is a valuable resource for staying up-to-date with industry developments and connecting with other professionals.

7. BITUROAD Conference

The BITUROAD Conference is an international event focusing on the latest technologies, innovations, and best practices in the road construction and bitumen industries. This conference is essential for professionals looking to explore new trends and network with experts in the field.

8. Global Asphalt Pavement Alliance (GAPA) Conference

This conference is hosted in various international locations by the Global Asphalt Pavement Alliance and brings together industry professionals to discuss global trends, sustainability, and advancements in asphalt pavement technologies. GAPA’s event provides a global perspective on the challenges and opportunities in the industry.

9. Conference on Asphalt Pavements for Southern Africa (CAPSA)

Held in South Africa, CAPSA focuses on the challenges and solutions for asphalt pavements in the Southern African region. The conference features technical sessions and networking opportunities that address regional issues and promote innovation.

10. Eurasphalt Congress

Taking place in various European locations, the Eurasphalt Congress brings together asphalt and bitumen professionals from across Europe and beyond to share knowledge, innovations, and best practices. It is a key event for staying updated on European industry standards and technological advancements.

11. China Bitumen and Road Conference

Hosted in China, the China Bitumen and Road Conference focuses on road construction and maintenance, featuring the latest technologies, research, and innovations in the asphalt and bitumen industry. This event is ideal for professionals seeking to learn about new developments and network with international experts.

These events are essential for industry professionals looking to stay current with the latest trends, technologies, and best practices in the asphalt and bitumen sector. Attending these conferences and meetings provides valuable opportunities for learning, networking, and professional growth.

Leading Training, Education, and Certification Providers

The asphalt and bitumen industry benefits from a range of organizations that offer specialized training, education, and certification programs. These programs are designed to enhance the skills and knowledge of industry professionals, ensuring they stay current with best practices, technological advancements, and industry standards. Here are some of the leading providers:

1. National Asphalt Pavement Association (NAPA)

NAPA provides a variety of training programs, webinars, and workshops covering topics such as pavement design, construction, maintenance, and sustainability. They also offer certification programs for professionals in the asphalt industry.

2. Asphalt Institute

The Asphalt Institute offers extensive training and certification programs including courses on mix design, asphalt binders, and pavement preservation. They also provide online courses and webinars for continuous education.

3. Institute of Asphalt Technology (IAT)

IAT offers professional development and certification programs aimed at improving the technical and managerial skills of asphalt professionals. Their courses cover a wide range of topics including materials, design, and construction techniques.

4. Transportation Research Board (TRB)

TRB provides a platform for education and training through its annual meetings, conferences, and workshops. They also publish research papers and reports that serve as educational resources for industry professionals.

5. Federal Highway Administration (FHWA)

FHWA offers a variety of training programs and technical assistance through its National Highway Institute (NHI). Their courses cover topics such as pavement design, construction, and maintenance, with a focus on federal standards and regulations.

6. European Asphalt Pavement Association (EAPA)

EAPA provides training and educational resources on European standards and practices in asphalt pavement construction and maintenance. They also offer workshops and seminars on various industry topics.

7. International Society for Asphalt Pavements (ISAP)

ISAP organizes conferences and workshops that provide educational opportunities for professionals in the asphalt industry. Their events focus on the latest research and technological advancements in asphalt pavements.

8. Asphalt Academy (South Africa)

The Asphalt Academy offers training courses and workshops on asphalt technology and pavement engineering. Their programs are designed to meet the needs of professionals in the Southern African region.

9. Pavement Preservation & Recycling Alliance (PPRA)

PPRA provides training and certification programs focused on pavement preservation, recycling, and sustainable practices. Their courses are designed to help professionals extend the life of pavement assets.

10. Roads and Transport Technology (RTT) Training Institute

RTT offers specialized training programs for road construction and maintenance, including courses on asphalt technology, pavement design, and quality control.

These organizations provide comprehensive training, education, and certification opportunities that help asphalt and bitumen professionals enhance their skills, stay updated with industry developments, and ensure compliance with global standards

Resources for Transportation, Storage, and Handling

The efficient transportation, storage, and handling of bitumen are critical aspects of the asphalt industry. Proper equipment, heating methods, and the use of modifiers and additives ensure the quality and performance of bitumen in various applications. Here, we provide a curated list of resources to help industry professionals navigate these essential processes.

Bitumen Tankers and Logistics

- Van den Bosch Transporten: Specializes in the transport of liquid bulk products, including bitumen, with a focus on safety and efficiency.

- TIP Trailer Services: Offers a range of tanker leasing and rental solutions for the bitumen industry, ensuring flexible and reliable transport options.

- Tiger: Provides comprehensive logistics solutions for the transportation of bitumen, ensuring timely and safe delivery.

Terminals and Storage Solutions

- Vopak: A global leader in independent tank storage, providing comprehensive terminal and storage solutions for bitumen and other bulk liquids.

- Transfigura – Puma: Specializes in the storage and distribution of bitumen, with a strong network of terminals and logistics services.

- Bitutainer co – TEC Containers: Provides specialized bitumen containers for safe and efficient storage and transport of bitumen products.

- Total Energies: Provides comprehensive solutions for bitumen production, storage, and transportation, with a focus on sustainability and innovation.

- Orlen – Unipetrol: Operates in Poland, Romania, Bulgaria, and Czech Republic, providing extensive services for bitumen storage and transportation.

- Guven Turkey: Specializes in bitumen storage and logistics in Turkey, offering reliable and efficient services for the industry.

Handling Equipment

- Verder Liquids: Provides a wide range of pumps and handling equipment specifically designed for the safe and efficient handling of bitumen.

- ITT Goulds Pumps: Known for their robust and reliable pumping solutions, ideal for bitumen handling in various industrial applications.

Heating Systems

- ThermoTech Solutions: Specializes in energy-efficient heating systems for bitumen storage and transport, ensuring optimal temperature maintenance.

- Chromalox: Offers advanced heating solutions tailored for the bitumen industry, focusing on energy efficiency and safety.

Modifiers and Additives

- Ingevity: Produces a range of additives and modifiers that enhance the performance characteristics of bitumen, improving durability and sustainability.

- Kraton Polymers: A leading provider of bitumen modifiers, offering solutions that enhance the elasticity and resilience of asphalt mixtures.

- Interchimica: Specializes in innovative additives and modifiers that improve the quality and performance of bitumen for various applications.

- Trinidad Lake Asphalt – Germany Agency: Provides high-quality natural asphalt and additives, enhancing the properties of bitumen for sustainable and durable applications.

- BASF: Offers a wide range of chemical additives and modifiers that enhance the performance and longevity of bitumen in road construction.

Safety Equipment

- DuPont Personal Protection: Supplies high-quality safety gear and protective clothing for workers handling bitumen, ensuring safety and compliance with industry standards.

- Honeywell Safety Products: Offers a comprehensive range of safety equipment, including protective gear and monitoring systems for bitumen handling environments.

By understanding and implementing the best practices and technologies in the transportation, storage, and handling of bitumen, industry professionals can significantly enhance the efficiency and quality of their operations. The resources provided in this section offer in-depth knowledge and practical advice on every aspect of bitumen management, from terminal operations to the use of performance-enhancing additives. Stay informed and equipped with the latest advancements to ensure your bitumen projects meet the highest standards of safety, sustainability, and performance.

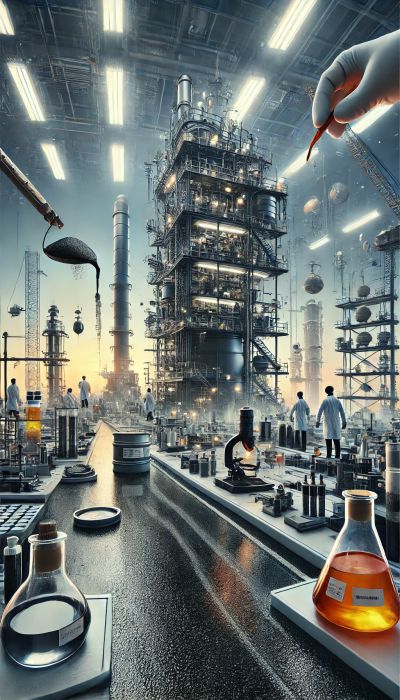

Asphalt Production Plant

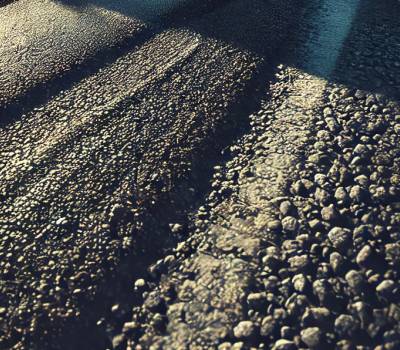

An asphalt plant is far more than just a manufacturing facility – it is the beating heart of road construction and maintenance. These plants produce the material that forms the very foundation of modern transport networks: asphalt, also known as macadam, coated roadstone, blacktop, or asphalt concrete. By combining carefully selected aggregates, bitumen binders, and often recycled materials, asphalt plants create the surfaces that carry billions of vehicles every day, underpinning economic activity and social mobility across the globe.

The appeal of asphalt lies in its proven performance. Renowned for its durability, weather resistance, and excellent adhesion to road surfaces, asphalt has become the material of choice for highways, urban streets, airports, and industrial sites. Its ability to withstand heavy traffic loads, adapt to different climates, and be recycled at the end of its life makes it not only practical but increasingly sustainable. Modern asphalt plants are therefore designed not just to produce material at scale, but to do so efficiently, cleanly, and with precision.

From batch plants offering flexibility for specialist mixes to continuous drum plants delivering high volumes for major projects, the technology behind asphalt production continues to evolve. Today’s plants incorporate sophisticated control systems, dust and emissions capture technologies, and energy-efficient burners, all of which contribute to more consistent quality and lower environmental impact. As the industry pursues net-zero targets, plants are also becoming testbeds for innovation, experimenting with warm mix techniques, bio-binders, and advanced recycling processes.

In many ways, asphalt plants embody the crossroads between tradition and innovation in construction. They continue to produce a material trusted for over a century, while simultaneously embracing new methods to meet modern demands for resilience, sustainability, and cost-effectiveness. Understanding the role and evolution of asphalt production plants is key to appreciating how the roads of tomorrow will be built.

Batch Mix Plants

Batch mix plants offer the highest level of flexibility in asphalt production, allowing precise control over the production process. They work by sequentially adding and processing controlled amounts of raw materials to produce asphalt in batches, each of which can have a different composition.

This is particularly beneficial when projects require varying mix designs or the incorporation of recycled asphalt. In a batch plant, the aggregate is dried and heated before being mixed with binder in a separate mixer, which means the plant can easily switch between mix designs. Batch plants are often the preferred choice for high-grade roads and other projects where quality takes precedence over quantity.

Drum Mix Plants

Drum mix plants are valued for their simplicity and efficiency. They produce asphalt continuously, which leads to higher production rates and lower operation costs compared to batch mix plants. All the ingredients are fed into the drum, where they are dried, heated, and mixed in a single process.

This continuous flow method means less start-up and shut-down time and less waste. Drum mix plants are typically used for large-scale construction projects where the same mix is used over an extended period, making them ideal for constructing highways and other major infrastructure.

Continuous Mix Plants

Continuous mix plants are similar to drum mix plants, but with the ability to alter the mix without stopping production. This flexibility makes them suitable for projects that require a constant supply of asphalt but might need adjustments to the mix properties during production.

These plants maintain a constant flow of materials through the drum, and adjustments to the composition are managed by varying the feed rates of the aggregate, filler, and binder.

Mobile Asphalt Plants

Mobile asphalt plants are designed for projects that require the asphalt production plant to be moved. These plants are ideal for remote locations or projects that move geographically, such as road or airport runway constructions. They can be dismantled, transported, and set up quickly, offering high levels of mobility and flexibility.

Despite their portability, they can still match the production rates of stationary plants and can produce a variety of asphalt mixes.

Stationary Asphalt Plants

Stationary asphalt plants are intended for permanent locations and offer the highest production rates. They are often found near city centers or large road construction projects where they serve a fixed geographic region.

These plants are typically larger and more productive than mobile or batch mix plants, with the ability to run 24/7 if needed. Stationary plants are designed to offer a long service life with consistent output and are capable of producing various asphalt mix types in large volumes.

Featured Asphalt Plant Articles

Asphalt Plant Components

Cold Feed Bins

Cold feed bins are essential storage units within asphalt plants that manage and supply the raw aggregates needed for asphalt production. Each bin holds a different size or type of aggregate, allowing for precise customization of the asphalt mix. These bins release aggregates in controlled amounts to ensure a consistent flow into the drying system, which is crucial for maintaining the quality and uniformity of the asphalt produced.

Conveyor Belts

Conveyor belts play a pivotal role in transporting aggregates from the cold feed bins to the dryer drum. They ensure a continuous and efficient flow of materials within the plant, thus maintaining a steady production pace. These belts need to be durable and capable of handling high loads to prevent breakdowns and maintain operational efficiency.

Dryer Drum

The dryer drum is a cylindrical vessel that serves to dry and heat the aggregates. It is equipped with a rotating mechanism that ensures even heating and removal of moisture, which is critical for the optimal bonding of the asphalt mixture. The drum includes a burner at one end that provides the necessary heat, typically fueled by gas, oil, or coal.

Burner

The burner is a key component that generates heat necessary to dry and heat the aggregates in the dryer drum. By burning fuel efficiently, it creates a controlled flame whose intensity can be adjusted to affect the temperature within the drum, thereby influencing the quality of the final asphalt mix.

Dust Collection System

A dust collection system is vital for capturing and filtering out the fine particles (dust) produced during the drying process. This system not only helps in maintaining air quality but also ensures compliance with environmental regulations. Effective dust collection prevents dust emissions, which can be harmful to plant personnel and the surrounding environment.

Hot Aggregate Elevator

The hot aggregate elevator is responsible for moving the heated aggregates from the dryer drum to the vibrating screens. This elevator must handle high temperatures and provide reliable transport to ensure a steady flow for the screening process.

Vibrating Screens

Vibrating screens classify the heated aggregates into various sizes by shaking them through progressively smaller meshes. These screens are crucial for quality control, ensuring that aggregates are properly sized before they are moved to the hot bins for temporary storage.

Hot Bins

Hot bins are compartments that store the hot aggregates after they have been sorted by the vibrating screens. They allow for the precise measurement and proportioning of aggregate sizes in the asphalt mix, which is critical for achieving the desired paving properties.

Weighing System

The weighing system accurately measures the hot aggregates, bitumen, and filler materials before they are mixed. This system is fundamental to achieving the correct formulation of asphalt, as it ensures that each component is added in the proper ratio.

Mixer Unit

The mixer unit is where the hot aggregates are blended with bitumen and filler materials to produce the final asphalt mix. This component is crucial for ensuring that the asphalt is homogeneous and meets the specified criteria for paving.

Asphalt Storage Tanks

Asphalt storage tanks hold the bitumen used in the asphalt mix. They maintain the bitumen at a controlled temperature to keep it fluid and workable until it is needed in the mixing process, thereby ensuring smooth and efficient operations.

Filler Silos

Filler silos store the mineral filler materials used in the asphalt mix. These materials, such as lime or cement dust, are critical for enhancing the properties of the asphalt, such as durability and resistance to deformation.

Control Room

The control room is the operational heart of the asphalt plant. It houses the control systems and panels that operators use to manage and monitor the entire production process, ensuring that the plant operates smoothly and efficiently.

Loading Area

The loading area is where the finished asphalt mix is loaded onto trucks for transport to construction sites. This area needs to be efficiently organized to handle the high throughput of material and to maintain the quality of the asphalt during the loading process.

Bitumen Storage and Handling

Effective bitumen storage and handling are pivotal for maintaining the quality of asphalt, which begins with ensuring the binder used has uniform properties such as consistency and temperature.

Proper management of these elements involves precise heating to keep the bitumen fluid, the use of high-quality tanks designed to maintain temperature without degradation, and safe, efficient transport mechanisms to move the bitumen from production to application sites.

Heating

Maintaining an optimal temperature is crucial as it affects the viscosity and performance of the asphalt. Advanced heating systems, such as hot oil and steam transfer fluid systems, have replaced direct-fired heaters for efficiency and safety.

Permitting and Safety

Navigating local regulations and safety codes, such as those from the NFPA and NEC, is essential for operational compliance. Safety measures must address high-temperature operations and potential hazards from steam systems.

Transporting

Bitumen is typically transported by rail or barge and then piped to storage tanks. Modern facilities utilize finned tubes for more efficient heat transfer during this process.

Tank Construction and Management

Tanks must be carefully constructed with attention to insulation and heating mechanisms. Management practices should prevent overflows and maintain bitumen levels above heating coils to prevent coking.

Environmental and Quality Control

Managing fumes and emissions is critical for safety and environmental protection. Quality control measures include segregating different types of bitumen and thorough testing to ensure product integrity.

Asphalt Plants Trends

Currently, the asphalt plant market is undergoing transformative changes, propelled by increasing urbanization, heightened sustainability goals, and technological advancements.

Here are the top trends that are defining the evolution of the asphalt plant industry:

Increased Infrastructure Development and Urbanization

There is a notable boom in global infrastructure development, including new road constructions, expansions, and maintenance of existing roadways. This rise in construction activities has led to a robust demand for asphalt, and by extension, for asphalt plants. Urbanization further compounds this demand, as expanding cities require more complex and robust road networks. The asphalt plant market stands to gain substantially from these ongoing developments.

Sustainability Practices

Environmental considerations are increasingly shaping the asphalt plant market. Manufacturers are innovating to introduce technologies that curb emissions and integrate sustainable practices within their operations. This includes enhanced burner designs that decrease air pollution, recycling methods that reintroduce reclaimed asphalt pavement (RAP) into new mixes, and the adoption of bio-based binders. These sustainable technologies are not only environmentally beneficial but are also cost-effective over the long term.

Automation, Process Control

Automation is becoming a cornerstone in the operation of modern asphalt plants. These facilities are now equipped with advanced computer systems that automate key production steps, from aggregate and binder input to temperature regulation during the mixing process, alongside automated quality checks. This shift not only streamlines production but also ensures a consistent quality of asphalt, crucial for the longevity of pavement.

Data Analytics, Telematics and Predictive Maintenance

Asphalt plants are increasingly incorporating data-driven technologies. Sensors throughout the plant monitor everything from material flows to energy use, providing a wealth of data that can be analysed to fine-tune operations, predict maintenance needs, and enhance overall efficiency. Asphalt plants can be remotely operated by the manufacturer, who can also run diagnostic tests and use predictive maintenance to avoid unexpected downtime and prolonging plant life.

Cold/Warm Mix Asphalt Technologies

Cold and warm mix asphalts represent a shift towards more energy-efficient asphalt production methods. Unlike traditional hot mix asphalt, these are produced at lower temperatures, reducing the energy required for heating and thus decreasing the environmental footprint. While it is not suitable for all types of projects, its use is expanding, particularly in applications where environmental impact is a significant concern.

Regulatory Compliance and Emission Controls

As regulatory frameworks around air pollution tighten, asphalt plant operators are compelled to adopt advanced emission control technologies. This includes the implementation of dust collection systems, low-NOx burners, and other mechanisms designed to meet stringent environmental standards and maintain operational licenses.

Evolution of Asphalt Mixing Plants

Looking to the future, the asphalt plant market is set to expand significantly. Demand driven by infrastructure needs will continue to grow; sustainability will guide technological and operational decisions; and advancements in automation and data analytics will refine production efficiencies.

Cold and warm mix technologies will provide necessary alternatives, while stringent environmental regulations will push for cleaner, more sustainable operations. These trends collectively forecast a dynamic path forward for the asphalt plants industry, ensuring it remains at the forefront of building the foundations for global transportation infrastructure.

The journey of asphalt mixing plants from simple, manually-operated setups to today’s high-tech operations illustrates a profound transformation driven by innovation and efficiency. This evolution reflects the industry’s response to increasing demands for durable and high-quality roads.

Origins and Early Developments

Asphalt’s use as a paving material surged in the late 19th century, prompting the development of basic asphalt mixing techniques. Early asphalt plants were rudimentary, involving manual mixing of aggregates and bitumen.

This process was not only labour-intensive but also inconsistent, affecting the quality of the asphalt produced. The introduction of mechanical mixers in the early 20th century was a significant improvement, mechanizing the blending process and increasing efficiency.

Advancements Through the 20th Century

The 20th century saw rapid technological advances in asphalt mixing. Rotary drum mixers and batch plants were introduced, revolutionizing asphalt production by enhancing both the rate and precision of mixing.

The adoption of continuous mixing processes further optimized efficiency, ideal for large-scale projects requiring substantial asphalt quantities.

Modern Innovations and Sustainability

The development of drum mix asphalt plants marked a major milestone, offering increased mobility and faster production rates. These plants support on-site asphalt production, which is especially beneficial for remote or difficult terrain projects.

Despite the benefits of drum mix plants, batch plants remain popular for their ability to produce precisely tailored asphalt mixes.

Environmental Considerations

Modern asphalt plants incorporate significant environmental safeguards, such as advanced pollution control systems and recycling technologies. The use of reclaimed asphalt pavement (RAP) in new mixes exemplifies sustainable practices that conserve resources and reduce costs.

Furthermore, modern facilities focus on reducing emissions and have embraced warm mix asphalt (WMA) technologies, which lower the temperatures required for mixing, thereby saving energy and reducing greenhouse gases.

The Digital Transformation

The latest evolution in asphalt plants involves automation and digitalization, enhancing efficiency and quality control. Smart plants utilize sensors and real-time data analytics to optimize production processes, adjust to changing conditions, and ensure consistent output.

These advancements allow for remote monitoring and management, boosting productivity and operational uptime.

Adaptability and Innovation

The evolution of asphalt mixing plants from basic to advanced exemplifies the industry’s adaptability and commitment to improvement.

Looking ahead, the focus on innovation, environmental sustainability, and smart technologies will continue to shape the future of asphalt production, ensuring it meets the modern demands of road construction.

Asphalt Plant Manufacturers

This list represents a sample of the top Asphalt Plant Manufacturers:

- ADM Asphalt Plant: Known for robust and reliable asphalt equipment, ADM Asphalt Plant provides a variety of durable asphalt mixing solutions tailored to meet specific customer needs.

- Alltech Industries: Alltech’s product range includes asphalt batch mix plants with capacities from 80 to 320 TPH, continuous asphalt plants, bitumen melting equipment, and road maintenance machinery.

- ALmix – Asphalt Equipment Company: Known for its robust and innovative asphalt equipment, ALmix excels in producing high-quality, durable machinery tailored to specific customer needs.

- Ammann: This Swiss company boasts over 150 years of expertise and is celebrated for its durable and comprehensive asphalt mixing plant offerings.

- Ardent: Emerging from India, Ardent is making a mark with its efficient and technologically advanced asphalt plants, contributing to the country’s road construction and infrastructure development.

- Astec Industries: Based in the USA, Astec Industries has been a leader in manufacturing a broad array of asphalt plants since 1972, known for their efficiency and longevity.

- Benninghoven: Part of the Wirtgen Group, German-based Benninghoven is recognized for its innovative technology in asphalt mixing plants, offering both mobile and stationary solutions.

- CMI Roadbuilding Limited: A prominent name in the industry, CMI Roadbuilding Limited offers a complete range of asphalt plants and has been innovating roadbuilding solutions for decades.

- Eagle (G.E.T.) Fabrications LTD: Eagle specializes in fabricating asphalt equipment that stands out for its reliability and performance, supporting road infrastructure projects globally.

- Ermont: Originating from France, Ermont is renowned for designing and manufacturing continuous asphalt plants, a staple in the industry since 1924.

- e-mak: Notable for its environmentally friendly asphalt plants, e-mak focuses on energy efficiency and recyclability in its designs.

- Intrame: Intrame designs and manufactures a wide range of asphalt plants known for their adaptability and capability to meet varied client needs.

- Kaushik Engineering Works: This company specializes in cost-effective and efficient asphalt mixing plants, with a strong focus on the Indian market.

- Lintec: Lintec provides innovative asphalt mixing plants characterized by their quality and flexibility, earning a respected status in the industry.

- Luton group: Luton group offers comprehensive solutions with their state-of-the-art asphalt mixing plants, known for precision and adaptability.

- Lyroad: Lyroad manufactures cutting-edge asphalt mixing plants with a focus on sustainability and advanced engineering techniques.

- Marini: As a part of the Fayat Group, Marini from Italy is renowned for its production of high-quality hot mix asphalt plants with global reach.

- Parker Plant: With over 100 years of experience, UK-based Parker Plant delivers reliable solutions for quarrying, construction, road infrastructure, and recycling projects.

- Polygonmach: Polygonmach stands out for its engineering precision and innovative designs in asphalt mixing technology.

- Sany: As one of the largest construction machinery manufacturers globally, Sany from China is known for its advanced asphalt batching plants.

- Stansteel: Stansteel is recognized for its high-quality, durable asphalt plant solutions tailored to professional asphalt producers.

- Tarmac International Inc.: Specializing in thermal rotary dryers, Tarmac International Inc. provides effective solutions for asphalt production.

- Tietuo: Renowned for its mobile asphalt mixing plants, Tietuo offers equipment that is easy to transport and set up, providing flexible solutions to the industry.

- XCMG: Xuzhou Construction Machinery Group, known as XCMG, is a leading manufacturer of construction equipment, including highly efficient asphalt mixing plants.

- Zoomline: Zoomline is a significant player with robust asphalt mixing plants that cater to complex and large-scale infrastructure projects.

This comprehensive list showcases companies at the forefront of asphalt plant manufacturing, each contributing with specific expertise and innovative solutions to meet the growing demands of the road construction industry.

Mastering Bitumen Course

“Mastering Bitumen for Better Roads and Innovative Applications” is a comprehensive course offered by École des Ponts ParisTech. Over four weeks, you will have the unique opportunity to learn from some of the world’s leading experts in bitumen. This course aims to build a robust understanding of the current realities and future perspectives of bitumen, providing you with the technical knowledge and insights necessary for effective and innovative applications in road works. As a European leader in bitumen markets, Total brings their extensive experience and commitment to sustainability and durability to this course, ensuring you gain valuable expertise in using bitumen efficiently and effectively.

École des Ponts, France’s oldest engineering school, continues to meet modern challenges by training engineers in crucial areas such as transport, housing, urban services, energy, and sustainable development. In this course, you will delve into the bitumen market, its manufacturing, transportation, and various applications, as well as explore its constitution, structure, and characterization. You will also learn about modifications and specific applications of bitumen, health and safety concerns, and recent research and innovations. With contributions from nineteen world-renowned experts, this course offers a comprehensive and diverse perspective on bitumen, integrating insights from research, industry, and end users. Join us to enhance your understanding and application of bitumen in creating better roads and innovative solutions.

Mastering bitumen for better roads and innovative applications

École des Ponts ParisTech

During the four coming weeks, best experts in bitumen will bring you their knowledge and experience to build a strong understanding of today’s realities and new perspectives on the future of bitumen.

Total is the European leader on bitumen markets. Innovation has always been the key to sustainability and durability in the products they develop. Their main objective here is to share technical knowledge and experience to insure bitumen are being used in the most effective and efficient ways for their different applications in road works.

Ecole des Ponts, France oldest engineering school, remains very much in the present, as it has always been, in training engineers in order to meet the needs of our society and citizens in key areas such as transport housing and urban services, but also in fields like energy, environment, climate sciences, land-use planning and sustainable development.

The course will teach you:

- Bitumen market, generalities, the manufacture of bitumen, transport, uses of bitumen, main developments and alternatives.

- Constitution, structure and characterization of bitumen – specifications – rheology.

- Modifications of bitumen and applications (road and roofing).

- Health, Safety, Environment & Quality concerns regarding bitumen, and examples of research & innovation actions.

Nineteen world recognized experts on bitumen are contributing to this online course.

The idea is to provide the broadest prism on this topic area with speakers coming from research, industry and end users.

Building Roads for the Future

Asphalt, bitumen, and pavement technologies remain at the centre of global infrastructure, shaping how societies move, connect, and grow. Yet the industry is no longer defined solely by volume or speed of production — it is increasingly judged by its ability to deliver long-lasting, sustainable, and cost-efficient solutions. From the integration of reclaimed asphalt pavement and bio-based binders to the adoption of warm mix technologies and smart plant controls, progress is being made on multiple fronts to reduce carbon footprints while enhancing performance.

What has become clear is that innovation in pavements is not a luxury but a necessity. Ageing road networks, climate pressures, and surging transport demand mean that traditional approaches can no longer keep pace. Instead, the industry is embracing circularity, digitalisation, and material science breakthroughs to create road surfaces that are more resilient, adaptable, and environmentally responsible.

As this month’s focus comes to a close, one message stands out: the future of pavements lies in collaboration between researchers, manufacturers, contractors, and policymakers. By uniting proven engineering with forward-thinking innovation, the sector is laying the groundwork for safer, greener, and smarter roads that will support generations to come. Asphalt, bitumen, and pavements may be familiar materials, but they are now being reimagined as the building blocks of tomorrow’s infrastructure.