Volvo updates H-Series 2 Wheel Loaders with their latest technology

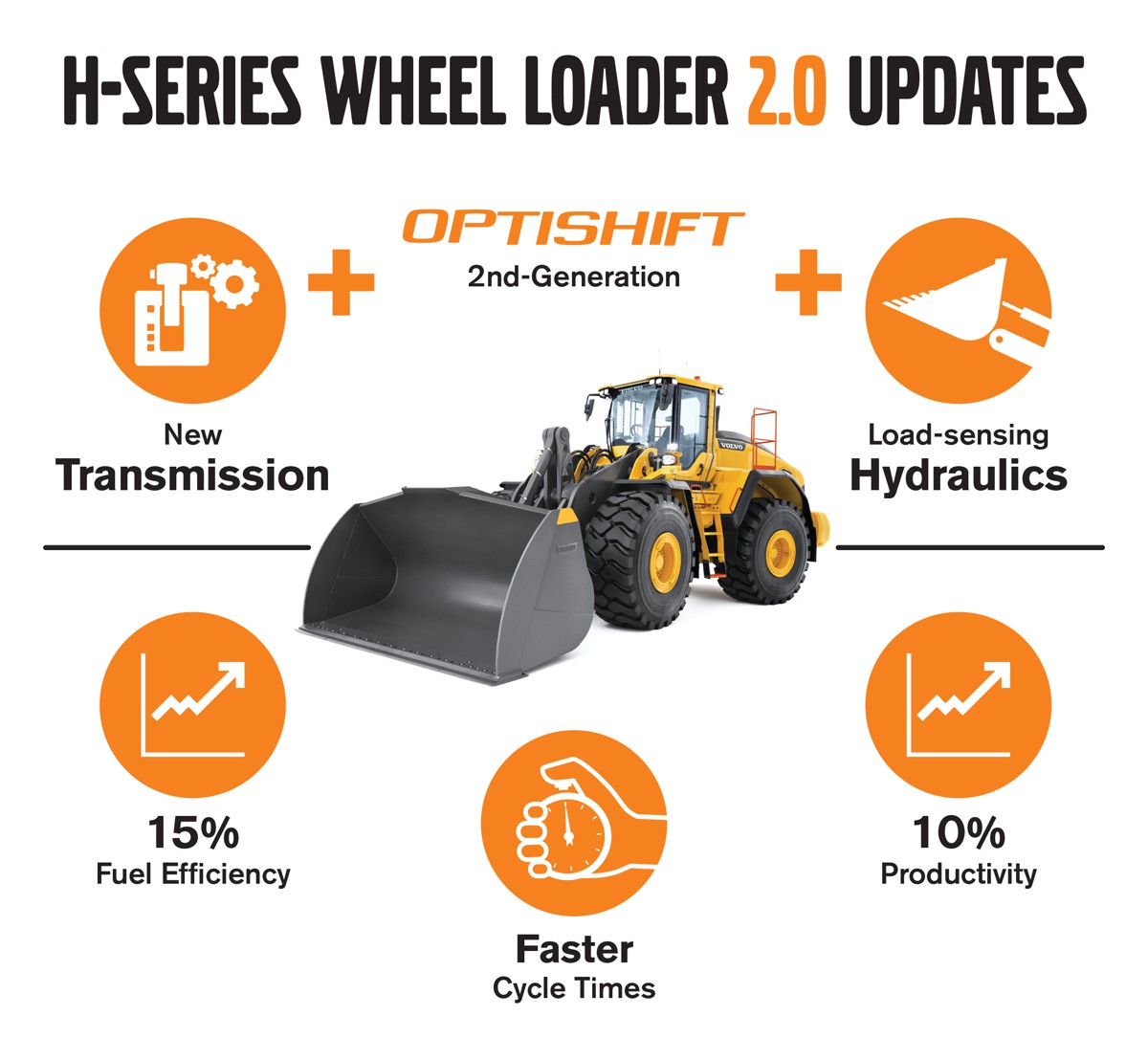

The new H-Series wheel loaders from Volvo Construction Equipment take a proven machine and add the latest technology, including the next-generation OptiShift and new load-sensing hydraulics and transmission. The result is a wheel loader lineup that boasts faster cycle times and improved fuel efficiency. The H-Series 2.0 Update is now available on the L150H, L180H and L220H, as well as the recently launched L260H. Additional models will soon follow.

“The ‘2.0’ in the name lets contractors know that they’re getting the same reliability and quality long expected from Volvo wheel loaders, but in a machine outfitted with the latest innovations to reduce cycle times, increase productivity and improve fuel efficiency. The most significant changes are a new transmission with shorter steps between gears and new torque converter with customizable lockup settings,” said Eric Yeomans, product manager, wheel loaders, Volvo Construction Equipment.

Next-level transmission

The 2.0 machines feature second-generation OptiShift technology that allows operators to customize the lock-up engagement of their machines. The improved OptiShift also integrates the Volvo-patented Reverse-By-Braking (RBB) function and the new torque converter with lock-up, creating a direct drive between the engine and transmission.

The H-Series wheel loaders have also been upgraded with a new transmission, which works in harmony with the engine and axles to improve stability and efficiency. The new converter delivers increased torque output, resulting in better performance at low speeds. For faster acceleration and smooth operation, the steps between the gears have been reduced. Combined with second generation load-sensing hydraulics – designed to enhance the responsiveness of attachments and improve the lifting and lowering speed of the boom – the updated H-Series wheel loaders deliver up to 10 percent better productivity than the G-Series.

Up to 20 percent greater fuel efficiency

In addition to the OptiShift and transmission improvements, the machine’s powerful engine, attachment optimization, and all-new dry P-brake, designed to eliminate drag losses, combine for significant fuel efficiency improvements. Other fuel-conserving features are the eco pedal, which applies a mechanical push-back force in response to excess use of the accelerator, and latest hydraulic system, which regenerates the oil in the lift/tilt cylinder circuits and deactivates the hydraulic pumps.

When you purchase a Volvo wheel loader and activate your free four-year CareTrack® subscription, you’ll receive our Fuel Efficiency Guarantee. If your machine’s fuel efficiency and productivity don’t meet the model-rated fuel efficiency levels, Volvo will reimburse a portion of the additional fuel.

With CareTrack activation, the H-Series wheel loaders are also eligible for a free year of ActiveCare Direct, the Volvo telematics service that provides 24/7/365 machine monitoring and fleet utilization reporting directly from Volvo. With ActiveCare Direct, customers can spend more time making informed fleet management decisions and less time sorting through data.

Any attachment, any application

The upgraded H-Series wheel loaders perform in a range of applications – from material handling and waste and recycling, to re-handling, slag handling and block handling. The machines come with a choice of dedicated Volvo attachments, including forks, grapples and buckets.

The new Volvo Re-handling buckets are designed with convex sides and an improved spill guard to ease filling and minimize spillage. As an option, the Boom Suspension System reduces bucket spillage, boosting productivity by as much as 20 percent on rough ground. Volvo’s unique Torque Parallel (TP) linkage delivers high breakout torque and excellent parallel movement throughout the entire lifting range.

Greater operator performance

The Volvo wheel loaders possess a number of features that improve operator performance, such as the latest bucket levelling function, which allows the bucket to return to level from dump and curl positions automatically. The H-Series loaders can be customized with either single or multi levers and a choice of three hydraulic modes, and the optional Comfort Drive Control enables the machine to be steered from a small lever – particularly useful for fast-paced truck loading operations.

With the optional Load Assist system, which keeps track of the amount of material moved, the operator can see real-time load information on a 10-inch Co-Pilot touchscreen display, helping to reduce under- and over-loading and the need for reweighing and reloading the truck.

At your service

Maintenance is easy on the H-Series wheel loaders thanks to the tilting cab that can be operated hydraulically to either a 30- or 70-degree angle, grouped service points, brake wear indicators on the wheels, maintenance-free rear axle cradles, reversible cooling fan, replaceable breather filters and outboard-mounted brakes. To reduce component wear, delayed engine shutdown can be scheduled to activate automatically. This new function turns off the machine when the turbocharger has cooled down to the appropriate temperature.

Backed for life

The H-Series wheel loaders are backed by the Volvo Lifetime Frame and Structure Warranty, which covers the frame, articulation joint and loader arm for the life of the machine under the initial owner.