Vermeer introduces MUD Hub Slurry Solidification System

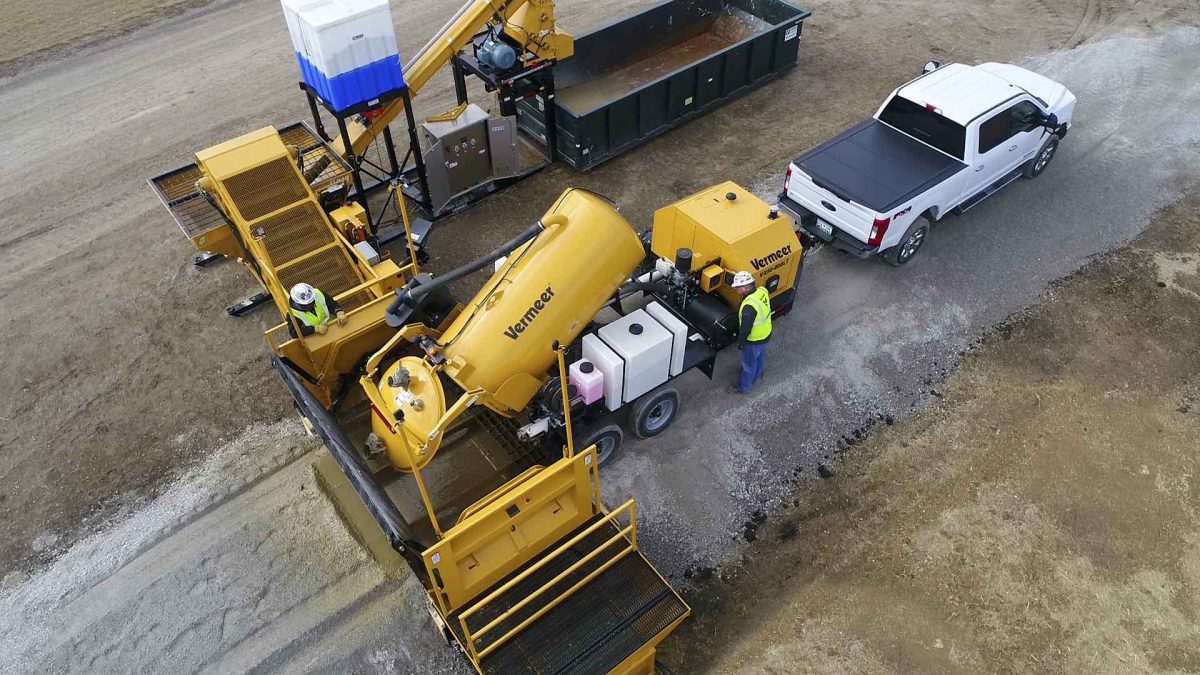

The new Vermeer MUD Hub slurry solidification system helps control the costs, time and complexity of drilling fluid management. Using the new Vermeer ST2000 slat tank and the Surface to Surface (STS) FL-243 solidification mixer, the Vermeer MUD Hub helps create stackable material for convenient transfer and disposal.

According to Adam Bates, product manager for Vermeer Corporation, the cost associated with properly disposing of used drilling fluid and hydro-excavation spoils are on the rise because of higher fees, reduced number of facilities accepting drilling slurry and increased travel time for offloading vacuum excavators. “Fluid disposal can have a substantial impact on a project’s success,” Bates said. “At Vermeer, we are committed to producing cost-effective solutions for fluid management. In addition to the Vermeer line of reclaimers for larger-diameter pipeline work, we now have the MUD Hub for contractors doing utility work.”

With the MUD Hub, vacuum excavator operators drive over the swing-open hatch above the 2,000-gal (7,570.8 L) ST2000 slat tank, designed for vacuum excavator dumping, to empty their tanks — no backing up to a pit required. A swing-open hatch helps to make the process more efficient and reduces excess splattering. The slurry mixture is then routed up the 84″ (213.4 cm) variable speed conveyor, where it is then loaded into the 750-gallon (2,839.1 L) infeed hopper of the STS FL-243 solidification mixer.

The STS FL-243 solidification mixer combines slurry from drilling fluid or hydro-excavation with a superabsorbent polymer before being discharged onto the ground or into a roll-off dumpster. In as little as 15 minutes, the slurry will begin to set up as a stackable material that is convenient to transport and may now be disposed of at a landfill, used as ground cover or added to composting mixes, depending on what additives were used in the drilling fluid.

The MUD Hub can be operated by one person from multiple control station locations for jobsite flexibility, and feed and dosage rates are made from the STS FL-243 solidification mixer’s control center. The ST2000 slat tank has a self-cleaning tank design, as well as slip-resistant floors.

With integrated lift points and a convenient setup design, the MUD Hub is convenient to transport with minimal preparation to begin running on a jobsite.