Could concrete roads enable fast charging of electric vehicles

‘Range anxiety’ is a major barrier to the widespread adoption of electric cars. Britpave, the infrastructure group, believes that concrete roads that charge electric vehicles as they pass over the road’s surface could be the answer.

Increasingly electric vehicles (EVs) are being promoted as the future for low or zero carbon transport. However, we are not there yet and until the issue of ‘range anxiety’ has been successfully addressed we are unlikely to be so. ‘Range anxiety’ is the fear that a vehicle has insufficient power to reach its destination and is considered to be a major barrier to the large scale adoption of all-electric cars. A number of surveys carried out by motor magazines has found that electric vehicles appear to fall short of claims from car manufacturers as to how far you can travel before you need to charge the battery by as much as 15%. This, and the lack of an adequate infrastructure of charging points are heightening the level of range anxiety.

According to the data company Emu Analytics there are only 16,500 charging points in the whole of the UK. It is estimated that with one million new EVs on UK roads within the next two years there needs to be a network of 100,000 charging points. Currently, only 3 per cent of supermarkets have a charging point. Rapid chargers, which can fill 85 per cent of an EV’s battery in half an hour are particularly scarce. Lidl has the highest number of rapid chargers at just 11. Across the whole UK there are only 1,500 rapid chargers. By comparison there are 9,000 petrol stations each with multiple petrol pumps that fill a tank in minutes.

“Faced with the lack of trust in manufacturer claims and the lack of an adequate charging network it is little wonder that ‘range anxiety’ is a barrier to more people buying EVs,” said Joe Quirke, Britpave chairman. “A new approach is required and increasingly the potential of concrete ‘eRoads’ that inductively charge EVs as they travel are being examined.”

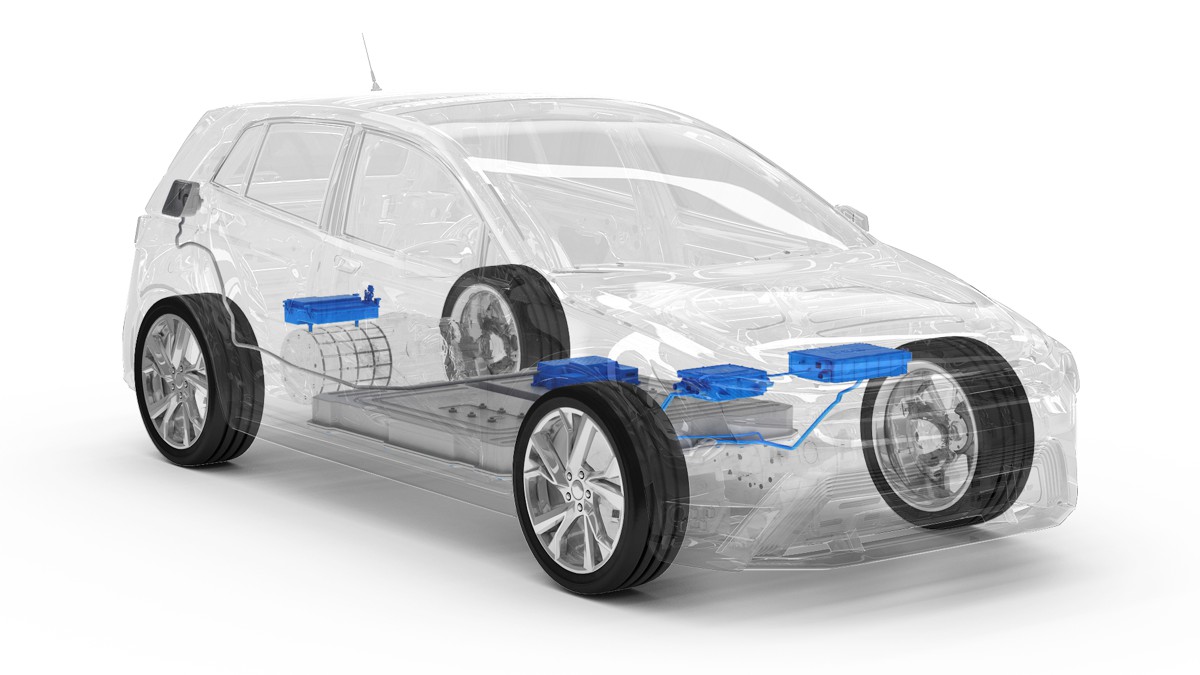

Inductive charging is where the EV battery is charged without the need to plug the vehicle into a charging point. The process is wireless and can be done whilst the EV is on the move or stationary. If the vehicle is moving the process is referred to ‘dynamic charging’.

Quirke points to a number of concrete eRoad options that are being researched and developed. A research project ‘Inductive Charging’ led by Flanders Make, the Belgium-based manufacturing industry research centre, tested the installation and use of inductive charging systems in concrete and asphalt roads. For the project, primary coil modules to create a magnetic field were installed within the road surface. The magnetic field creates an electric current in a secondary coil placed on the vehicle’s undercarriage which feeds the charge to the vehicle’s batteries.

The research found that energy efficiencies of 90 per cent were achievable, only 4 per cent less than using a charging point, and it emphasised the importance of the road surface durability for the successful operation of the installed module. The findings of the research had been used for the construction of 200Kw bus charging stations in Bruges, Belgium, and Braunschwieg, Germany. In Bruges, precast concrete bus stops take 15 minutes to wirelessly charge parked buses after every 12km travel loop.

In France, the recent FABRIC project, funded by the EU, studied the technological feasibility, economic viability and socio-environmental sustainability of dynamic conductivity. A wireless electric vehicle charging system, developed by Qualcomm Technologies Inc, was installed in a 100m test track at Versailles, Paris. The system successfully charged two Renault Kangoos EV with 20Kw at speeds of over 62mph. The research concluded that wireless power transfer for on-the-move dynamic charging is feasible with current road designs that with due consideration of use, future maintenance and whole lifecycle costs.

While in Israel, ElectReon Wireless has successfully charged a Renault Zoe inductively while driving. This was achieved along a 20-metre long section of track equipped with coils embedded in a section of road in the coastal town of Beit Yanai in Israel. During the test, ElectReon proved an energy transmission of 8.5 kW with an efficiency of more than 91 per cent. The company expects to be able to increase the transmission power to over 15 kW during forthcoming tests.

“What is being underlined by the research is the need for the road surface to have long-term durability and minimum maintenance. Both are inherent characteristics of concrete roads,” said Quirke. He added: “A further benefit of concrete roads for the installation wireless modules is that in hot summer temperatures they, unlike asphalt, do not melt. Such melting could dislodge and compromise the positioned embedded wireless system.”

Other exciting possibilities include making the actual concrete road itself conductive. Australian-based Talga Resources are mixing graphene into concrete to make it conductive and so charge an EV whilst it is driving. Previously, developed to enable self-heating concrete roads, the company has found the addition of a graphene, graphite and silica-rich by-product of ore processing provides a concrete that is not only highly conductive – 0.05 ohm.cm volume resistivity – but is also stronger. The company is activity examining the potential of electrically conductive concrete to provide both dynamic and stationary wireless inductive charging for EVs.

In Germany, Magment – magnetizable concrete materials – are being developed by using magnetic ferrite particles as aggregates. Magment concrete consists of 87 per cent magnetisable aggregates which is waste product from the manufacture of ceramic ferrites and the recycling of electronic scrap. It allows energy to flow into a coil to inductivity charge vehicles as they pass. The proposal is to cast (either precast or insitu) concrete ready-to-connect coil modules that contain all the required wiring including optional sensors for integration into road construction.

“Durability and minimum maintenance are key for future eRoads. This is especially so as the vehicles, particular heavy goods vehicles, will be travelling on the same path in order to charge. The road surface must, therefore, not prematurely deflect or rut. Concrete roads have a performance life of 50-60 years and are so fully able to provide the required long-term durability,” said Quirke. “Concrete eRoads should have a very significant role to play in helping deliver the widespread adoption of electric vehicles and the removal of reliance on fossil fuels.”