Tenstar Simulations showcasing their World of Simulation at CONEXPO 2020

Tenstar Simulation, a specialist in the simulator industry that offers a wide range of professional machine education simulators for Construction, Transportation and Agriculture, is showcasing their World of Simulation at ConExpo 2020 in Las Vegas.

The range of Tenstar simulators are developed by engineers in close cooperation with key players in the respective markets to deliver realism, a professional machine feeling and realistic work scenarios that provide the ultimate training tools to educate machine operators.

Tenstar’s graphics are designed with an emphasis on real machine models and actual working environments.

Each machine type has a set of carefully developed exercises, optimised to train the students in areas of maintenance, driving skills, maneuvering skills, safety and special accessories for example GPS and tilt rotator operation.

Excavator working in an Extended Reality!

Varjo XR-1 is a mixed reality simulator with photorealistic visual fidelity, ultra-low latency and integrated eye tracking. Switch seamlessly between mixed reality and full VR to deliver the benefits of both worlds in one device. That means you can be in different environments and manipulate your surroundings with pixel-perfect control, so you will see your actual hands and body as well as the real seat with joysticks and touch screen and the rest is a virtual simulation.

Dozer Machine Control – NEW!

The Tenstar Excavator Simulator is already fully compatible with industry leading machine control providers such as Leica, Topcon, Trimble and Novatron, and now the Tenstar Dozer is working with Trimble Earthworks so trainers can be confident their machine operator can use the machine control system prior to going on to a live construction site.

Tenstar Steering Wheel – NEW!

The brand new steering wheel unit is adjustable and adaptable for every relevant machine type in the range.

A durable metal cover, direct drive and immersive dynamic range force feedback enables the most realistic user experience in the industry.

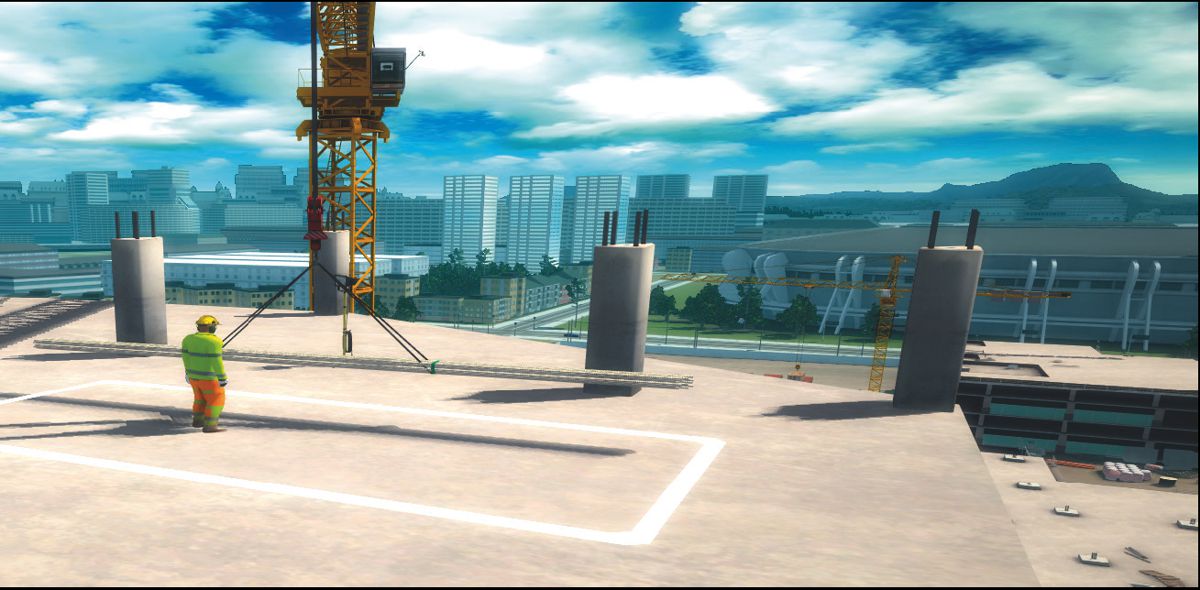

Tower Crane and Crane Lorry – now with VR!

Tenstar Tower Crane and Crane Lorry simulators offer a full-scale training tool for the education of crane operators and now are also available with VR headset, which provides a realistic environment with self-instructive exercises that reflect real-life machine behaviour and operations.

Machine Control Training Simulator For Excavator – now also for Dozer!

With the ever increasing adoption of machine control grading systems on construction sites, the need for quality training to enable the users to get the best from their investment has never been higher.

It is not always practical to teach operators on the use of machine control once a construction site is in full production, so this is where simulated training offers an efficient method to educate an operator on all aspects of the grading systems.

During the simulation training the operator can fully focus on understanding every aspects of the grading system. Once on site with the machine no time is lost, the site benefits from the efficiency and cost savings which the machine control system delivers.

Benching, Laser and GPS methods are all available when using the system, this allows the student to decide when it’s correct to use each method of measurement based on the site application.

For example a trenching application can use the laser 2D guidance solution whilst the highway construction uses the 3D GPS control. The system can also measure and record data for as-built purposes and/or design creation.

The trainer can be confident the machine operator has the ability to use the machine control system prior to going on to a live construction site. Users also have the option to load their own design files or use the pre-set design examples.

Through very close working partnerships Tenstar Excavator Simulator is compatible with industry leading machine control providers such as Leica, Topcon, Trimble and Novatron. Now the DOZER can be added on the same hardware, working together with the Trimble Earthworks.

Simply by adding the chosen machine control providers screen interface to the simulator hardware the user has the ability to fully train as if installed on an actual machine.

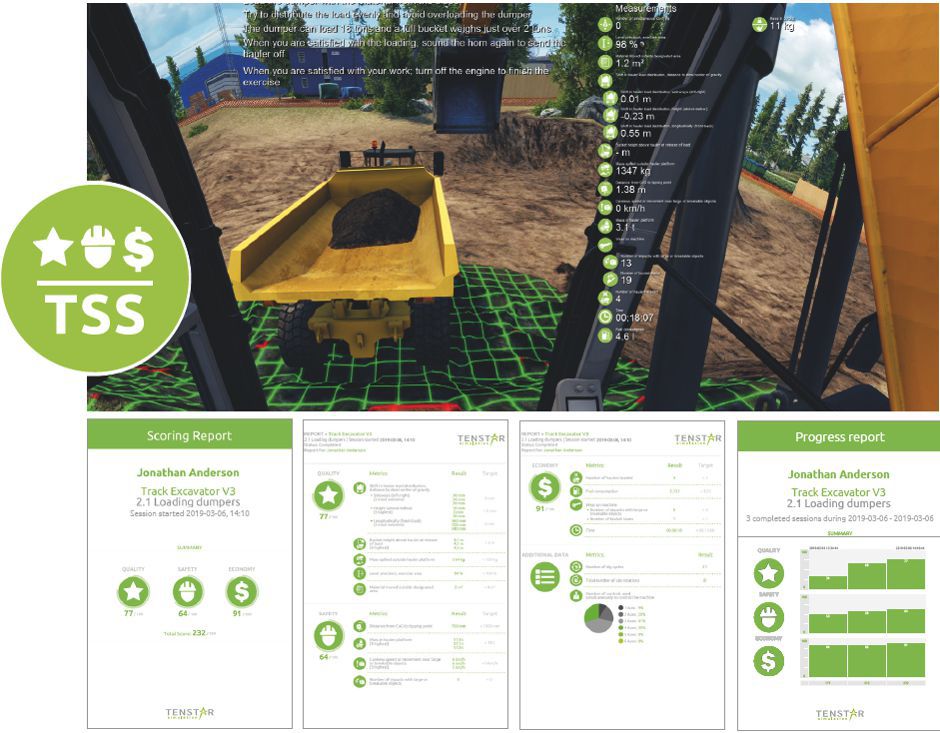

Tenstar Scoring System – TSS

The Tenstar Scoring System provides performance-based scorecards and progress charts – focusing on Safety, Quality and Economy – enabling evaluation, feedback and incentive for student progress and development.

The scorecard and progress charts allow the instructor to track each student’s development making it possible to give unique and personal instructions for every student. The Scoring System also enables real time feedback, to the student, ensuring continued and focused improvement in key areas.

- Administrator reporting tool enables the teacher to preload students details providing each user with a unique login identification.

- Individual feedback on performance score, helping students understand how to operate machinery in a safe, economic and high-quality manner.

- Scorecards can record every time the student trains using the simulator, both students and instructors can follow progress and identify areas requiring improvements.

- Tenstar Scoring System measures a wide variety of data and metrics, which is often not traditionally possible.

Tenstar Record and Replay – TRR

Tenstar Record and Replay can record the whole training session and store it, all simulated features included, as a small file with a ground-breaking solution. Thanks to this it is possible to replay any situation in slow motion or stop it completely.

The replayed exercise can be viewed from any chosen angle at any given time. This timeline feature provides the instructor with an extended tool to follow up and provide feedback to the student. This makes it possible to understand why a situation occurred and how it could be prevented. The replay can be run on the simulator via the touch control or at the teacher’s computer both with a unique intuitive interface.

Eye Tracking

Eye tracking is starting to be used more and more within our simulators. It will optimise learning and feedback to the student on how for example the student uses the mirrors, identify dangerous/ sensitive objects and the general planning of the task.

Metrics created with eye tracking can be fed into the software and TSS for immediate feedback as well as going into reports. Face recognition can also be included for easy login and continuous identification of the user.

Combining the eye tracking with TRR – Tenstar Record and Replay will provide an entirely new training layer when analyzing the users behavior.

Multi Machine Environment – MME

Multi Machine Environment – MME, allows the users to network multiple simulator seats/machines into one site environment. An example of this can be seen in the road construction exercise where a track excavator work with two articulated dump trucks delivering material to a dozer carrying out final trimming on the highway. Multiple users can enter the environment making interactive cooperative training possible.

“This is a groundbreaking feature in simulation as a training tool to prepare the student for the real interaction with other users”, says Fredrik Alexandersson, senior developer at Tenstar Simulation.

VR WA (walkaround)

With one computer connected with a VR headset and hand controls we create a training station for one person placed inside of the virtual training environment. It is possible to use the hand controls to move around, grab things, checking machines and now even communicating with operators in other machine simulators real time.

VR WA person in MME

The world’s first person interaction within a Multi Machine Environment for simulated earthmoving machines.

Without any additional simulation hardware and simply adding a computer, VR headset and hand controls we can insert another person into the Multi Machine Environment.

This person can interact on site inside the virtual environment with other machines, for an example:

- an instructor giving instructions

- a surveyor/grade controller setting out for machines

- a machine banksman/traffic marshal/site foreman

This provides non machine operators the unique opportunity to interact with site operations in a safe and controlled environment, the training possibilities are endless!

VR WA machine – introduction and inspection

Experience and learn about different machines and their inspection procedures in a Virtual Reality environment, where no simulation hardware is required, only a computer, VR headset and hand controls!

This allows the user to interact within a comprehensive, immersive and life-like manner within the machine environment and to get to know the different machines and features and make daily pre-start inspections using a tick checklist as you progress – endless training possibilities for the future.

Combination simulator – One Simulator – Many Machines

Tenstar Simulation offer the ability to combine multiple different machine types within the same simulator hardware providing the benefit of flexible and cost effective learning.

Tenstar simulator is offering a varied education criterion for the teacher.

Switching between each machine takes seconds and does not require exchanging or switching control levers. Tenstar provides realism utilizing professional hardware together with life-like movement through our state-of-the-art fully user adjustable motion base unit.

Tenstar Construction Simulators

- Track Excavator

- Wheel Excavator

- Wheel Loader

- Articulated Dump Truck

- Dozer

- Grader

- Tower Crane

- Telescopic Handler

Tenstar Transportation Simulators

- Truck with Trailer

- Long Hauler

- Bus

- Car

- Wheel Loader

- Crane Lorry

- Timber Crane Truck

- Forklift

Tenstar Agriculture Simulators

- Tractor

- Combine Harvester

- Wheel Loader

- Telescopic Handler

- Forestry Forwarder

- Forestry Harvester

Tenstar utilises the latest technology and are rapidly expanding in an exciting industry

Tenstar training simulators are developed using advanced programming combined with modern electronics and hardware including VR technology, professional machine

components and motion platforms.

With their head office located in Sweden and with a rapid growth strategy, Tenstar are primarily focused on schools, education establishments and machine manufacturers.

Tenstar have an established sales organisation covering Europe, but have customers all over the world that drives them to continually expand outside of Europe. You can visit Tenstar at Conexpo in the Central Hall C1-C2 Booth C22032.