Metso expands revolutionary Megaliner to include discharge systems

Megaliner™ for discharge systems is a unique solution that simplifies and speeds up grinding mill relines by up to 50%, as well as dramatically improves safety for mining operations.

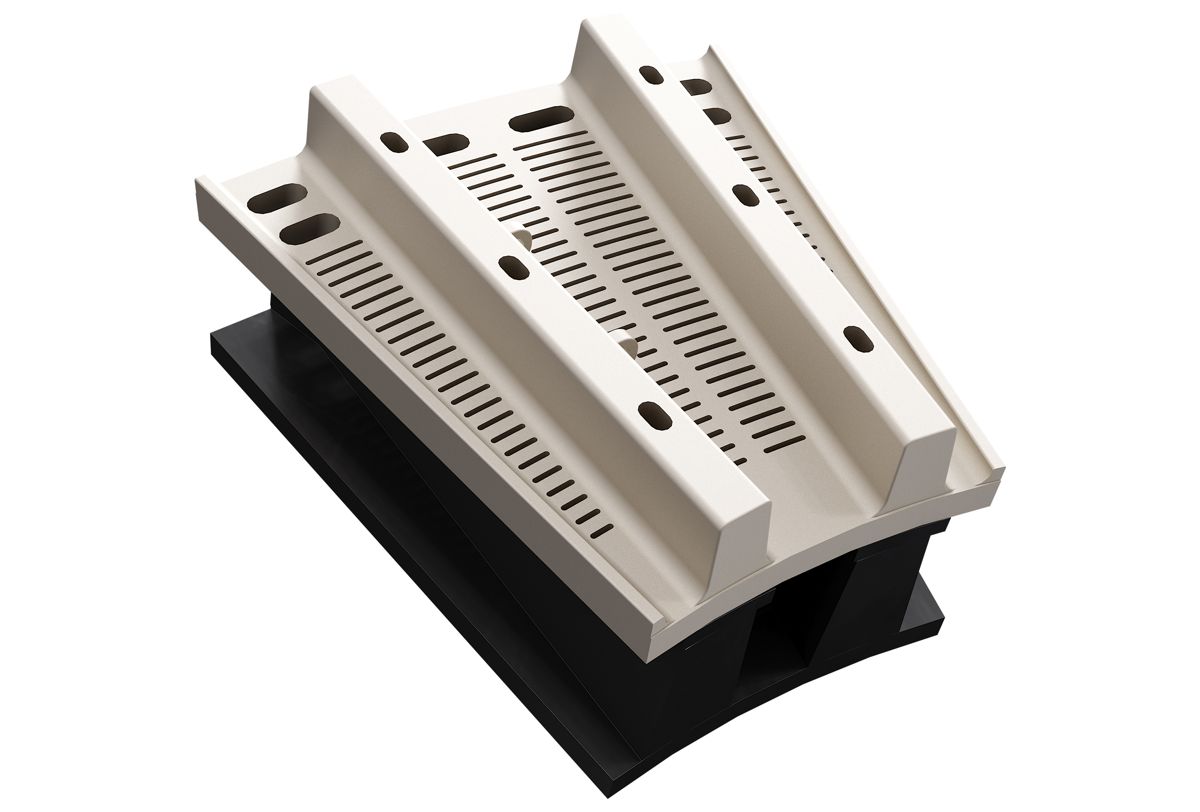

The new Megaliner for discharge systems integrates dischargers, grates, lifter bars and filling segments in one unit, reducing the number of components used by as much as up to 70%.

The new solution has outstanding safety benefits. Megaliner has a minimized number of attachment points and the bolts used to attach the liners are inserted from the outside of the mill, meaning that no workers are needed in the danger-zone inside the mill. The work can instead be performed on steady and safe platforms.

In addition, the liner bolts are much shorter and well protected from dust, corrosion and general mechanical damage, making them longer lasting and easier to remove. The traditional long bolts through the grate, the pulp lifter and the mill discharge head are not used, making it up to 70% faster to knock out the bolts. It also eliminates the need for risky and expensive recoilless hammers.

“The discharge system of a grinding mill is the most complex and time-consuming part of the mill to reline. There are also significant risks involved when changing out heavy liners in a tough environment under time pressure. We are therefore thrilled to be able to offer a faster, but at the same time much safer solution that will reduce risks and increase uptime for our customers,” says Anssi Poutanen, Vice President, Mill Lining Solutions, Metso.

Megaliner is now available for all sections of a mill

Metso first launched the Megaliner concept in 2012. Since then, the groundbreaking innovation has been installed in over 30 mills and has helped many mining customers globally to improve uptime and safety. With this latest innovation, Metso can now offer Megaliner for all sections of horizontal mills; the head, the shell and the discharge system. Megaliner is suitable for large AG, SAG and ball mills where modern liner handlers are available.

Metso is a world-leading industrial company offering equipment and services for the sustainable processing and flow of natural resources in the mining, aggregates, recycling and process industries. Metso employs over 15,000 people in more than 50 countries.