Cortec VpCI Emitting Corrosion Protection Technology advances metal protection

Cortec’s longstanding commitment to environmental responsibility resulted in expanding portfolio of sustainable products. Cortec’s VpCI® devices protect metals by conditioning enclosed environments with corrosion inhibiting vapour molecules.

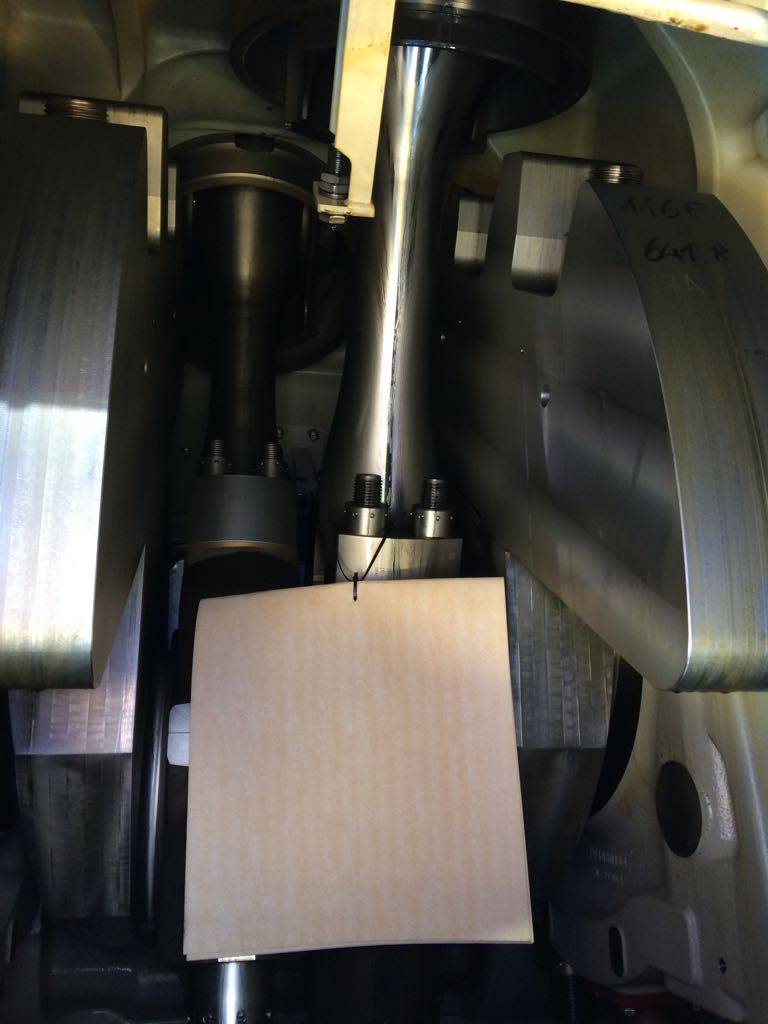

Molecules are attracted to and adsorb onto metallic surfaces resulting in the formation of nanofilms, very thin microscopic molecular layers of corrosion protection. These devices do not adversely affect or alter the appearance, conductivity, mechanical integrity, or optical functionality of the components protected. Emitting devices are environmentally responsible, economical and compact.

First in line, Eco Emitter is a non-hazardous and highly engineered, biodegradable device designed to provide corrosion protection for most sensitive assets such as electronic and optical equipment and components.

VpCI’s emit from the device and saturate the enclosure via diffusion, filling all void spaces and recessed areas with protective vapor molecules. EcoEmitter® was designed with the environment in mind in a concerted effort to reduce our carbon footprint. The polymeric cup has been selected to replace polyethylene and is constructed from OK Biobased 3-Star rated resins containing 60-80% renewable carbon content.

The breathable membrane that emits VpCI® is constructed from biobased fibres. EcoEmitter®is extremely simple and convenient to install. Simply select an enclosed space where corrosion protection would be useful and stick the EcoEmitter inside®.

Another sustainable option is BioPad®, Cortec’s unique flexible corrosion inhibiting device constructed from biobased non-woven material. It is an excellent environmentally responsible packaging option for corrosion inhibition. Its high VpCI® concentration, in combination with a thin design, results in material reduction by up to 94% in comparison to similar polyurethane foam emitting devices. It is very easy to use simply by placing the correct size of Bio-Pad® into your package. Bio-Pad® is specially designed with VpCI® impregnated throughout the substrate.

A third eco-friendly and sustainable solution for corrosion protection is Cortec’s EcoDevice®, constructed from biobased fibres. Convenient to install, it is especially designed to provide corrosion protection for small enclosures such as tool boxes, control panels, electrical cabinets, instruments, and other electronic/electrical enclosures.

Each individual EcoDevice® protects up to 42 L (1.5 ft³). It is very effective in polluted and humid environments and does not interfere with electrical, optical, or mechanical performance. Cortec’s emitting devices will provide excellent corrosion protection to your assets while being safe for the environment making them one of the best options on the market.