New Ty-Deck Ultra Screen Media reduces or eliminates Rinse Screens

Haver & Boecker Niagara introduces Ty-Deck Ultra modular screen media. The polyurethane screen media offers a robust solution for mining operations seeking more sustainable options in applications requiring production increases combined with high abrasion resistance.

Ty-Deck Ultra’s accelerated screening action cleans material without the use of water, therefore reducing the need for tailing dams. With a 50% longer wear life than the original Ty-Deck, the screen media panels are an ideal choice for screening ores, especially on a vibrating screen’s second deck. The new product has been developed based on customer feedback indicating a need for screen media that eliminates the use of water use.

“The well-being and sustainability of our customers’ operations is important to us,” said Clayton Carvalho, managing director of Haver & Boecker Niagara’s Brazil operation. “Recent events have made it clear that there is a high possibility of producers facing water restrictions or bans. We want to offer operations a solution so that they can maintain production, as well as provide a positive environmental impact by virtually eliminating the use of water with Ty-Deck Ultra.”

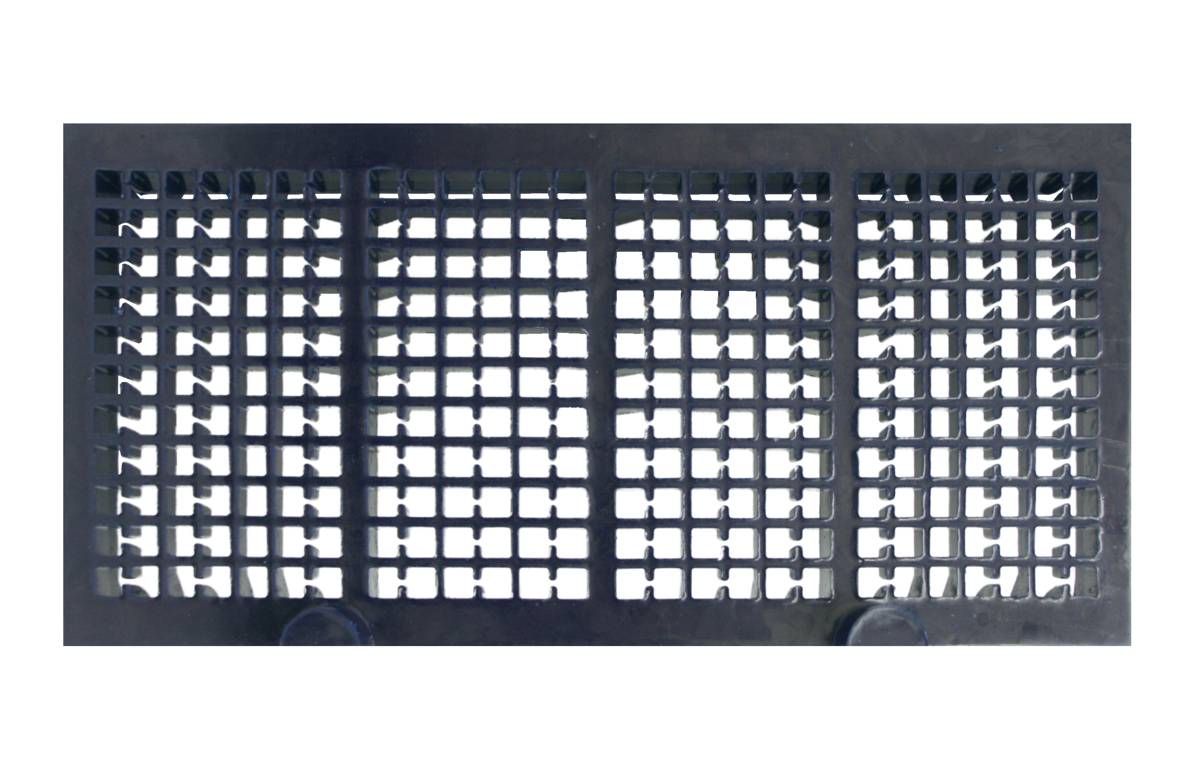

Ty-Deck Ultra screens feature H-shaped openings made up of individual strips of polyurethane. Each opening is separated by two independent extensions parallel to each other. The strips vibrate independently to increase material acceleration, improving material separation and cleanliness, and often eliminating the need for a rinse screen. The rapid movement of the strips also virtually eliminates pegging and blinding.

Ty-Deck Ultra is ideal for handling abrasives with a top size of 50 millimetres on the second deck in non-impact areas. The polyurethane is poured open cast, allowing it to permanently harden when cured to maintain its chemical properties, and resulting in a 1.5-2 times longer wear life than injection moulded screen media.

Ty-Deck Ultra joins Haver & Boecker Niagara’s extensive line of Tyler engineered media including Ty-Max, Ty-Wire, Ty-Dura, Ty-Plate and the original Ty-Deck.