Doka CONTAKT brings digitalisation to the construction site

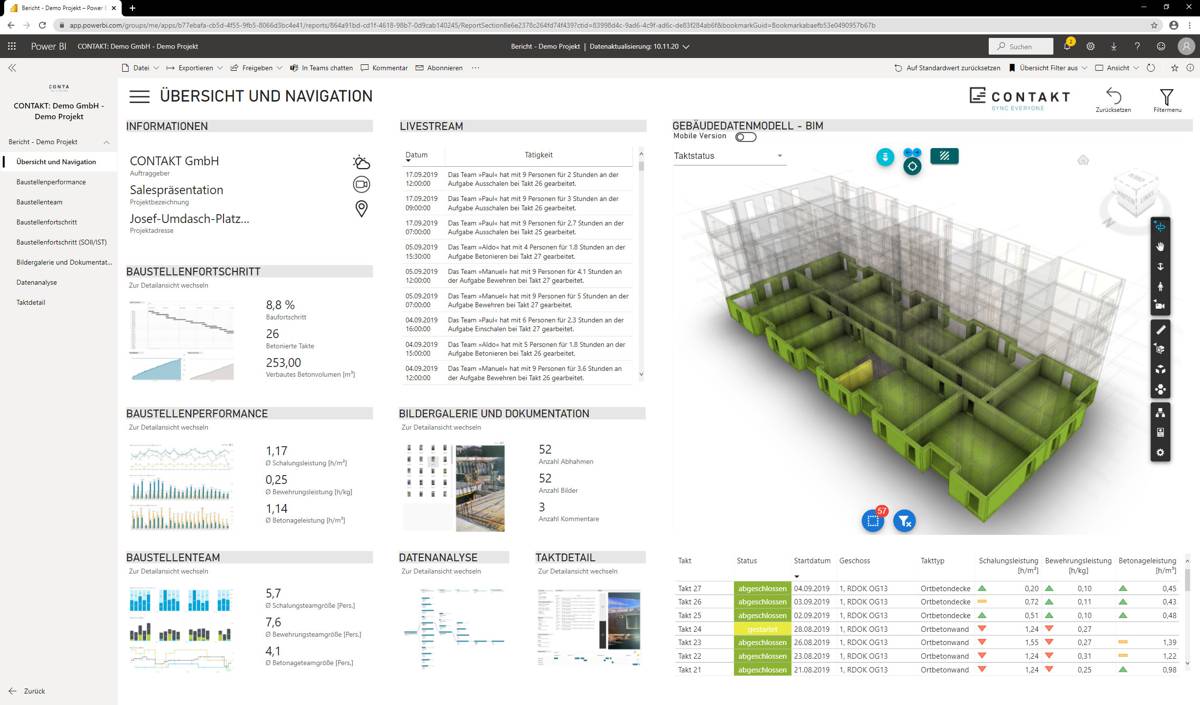

With the sensor-based CONTAKT construction site software, Doka offers a digital solution that brings the construction project planned in BIM to life on the real construction site. The new Fröschl office building is an outstanding example of CONTAKT at work.

When it comes to planning and the collaboration of all the many participants involved in a construction project, digital tools can significantly improve productivity and cost savings. It’s not primarily about working faster – these tools facilitate coordination and successful planning to decrease cycle times. Constant access to all the relevant planning information and the ongoing analysis of construction site data in real time simplifies existing processes.

CONTAKT: Construction process always in focus with software and sensors

How can you ensure maximum productivity in cycle planning, team positioning and material disposition when planning and executing your construction project? That’s easy: digitally, using CONTAKT. The sensor-based software solution provides direct support during on-site execution. Therefore, foremen and site supervisors can plan, allocate, and compare materials, resources, and personnel at the cycle level and gain valuable insights. All processes on the construction site are monitored in real time and automatically documented.

As soon as the planning data based on a BIM model has been uploaded to CONTAKT, it is possible to work with the comprehensive digital management tool. The cycle planning is carried out completely digitally and directly in the building model with CONTAKT instead of a 2D plan. The work packages generated from this can be quickly assigned to the construction site team regardless of location and ensure a structured workflow.

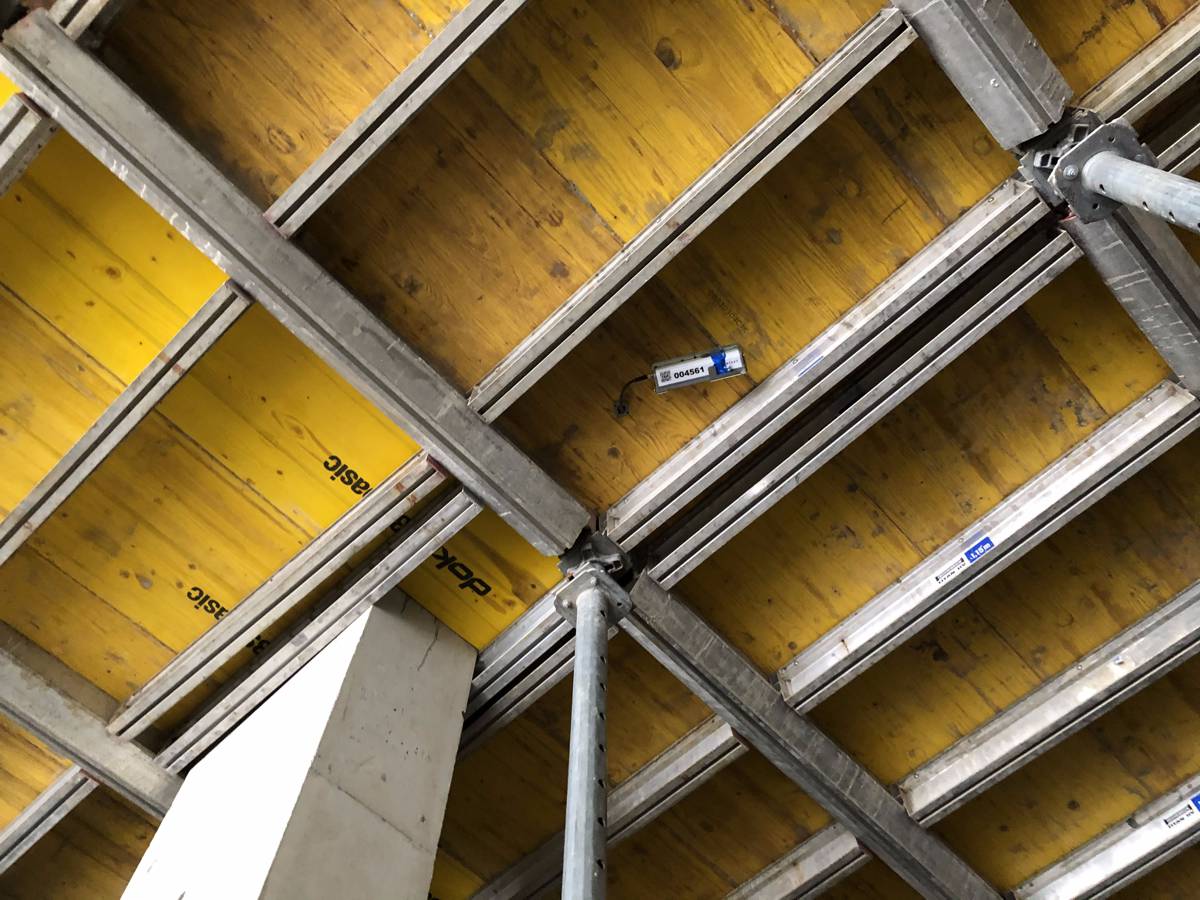

In addition, the CONTAKT sensor technology has a role to play. Attached to the formwork, it delivers live and automatic information such as crane lifts per composite, position or concrete maturity to the CONTAKT dashboard. In this way, all progress is recorded on the cycle and directly in the building model, which opens up a completely new and transparent approach to construction progress measurement. Deviations can be reacted to quickly, and the completion of the project can be kept on schedule.

Since CONTAKT is also easy to use with tablets and smartphones, photos of the construction site can be uploaded in the app and automatically assigned in the building model at the cycle. The individual process steps can thus be documented pictorially and tracked in detail.

Successfully applied: Smart Interaction – CONTAKT with Concremote

CONTAKT was selected because of the tight schedule for the Fröschl construction company’s six-storey office building in Hall, Tyrol. Without changing the staff deployment on the construction site in Hall, the team could complete seven cycles per week instead of the five cycles envisaged in the plan. “The timed cycle of construction stages increased the productivity of the construction team, with everyone already knowing what needed to be done each morning and all participants able to see the information on the model”, said Christian Mair, builder at Fröschl AG & Co KG. In contrast to other solutions, CONTAKT was also able to offer additional added value with an automatically generated site logbook and imported daily and weekly plans.

Another significant advantage of CONTAKT was that the field-proven Concremote technology for measuring and optimising concrete performance is fully integrated. Simply measuring the early strength of the concrete in the ten ceiling components of this project resulted in a 25% saving in ceiling formwork, with a compressive strength of 29.6 MPa achieved just 25 hours after pouring.

The Fröschl project highlights how digital solutions and their interaction can advance the construction process and significantly improve productivity on the construction site.

For Doka, this is just one more reason to continue forging ahead, working with customers to develop the company’s digital services, expanding their product range, and bringing even more to the construction site. More details on individual digital services can be found here.