AutoStem’s disruptive technology driving change in the rock-breaking industry

Innovation is paramount to ensuring continuing market relevance and customer satisfaction. AutoStem™ Technology is a world leader in the research, development, and commercialization of innovative alternative rock-breaking technology.

The world patented and award-winning AutoStem™ Generation 3’ is an environmentally friendly disruptive technology and notably the world’s safest alternative to and replacement of conventional explosives.

The many novel innovations found in AutoStem’s flexible product range have been pioneered to overcome and resolve several challenges when compared to conventional explosives. The developers highlight the difference, improvements, and many benefits these products offer over conventional products and methods when considering blasting solutions that meet blasting challenges otherwise unheard of in the explosives industry.

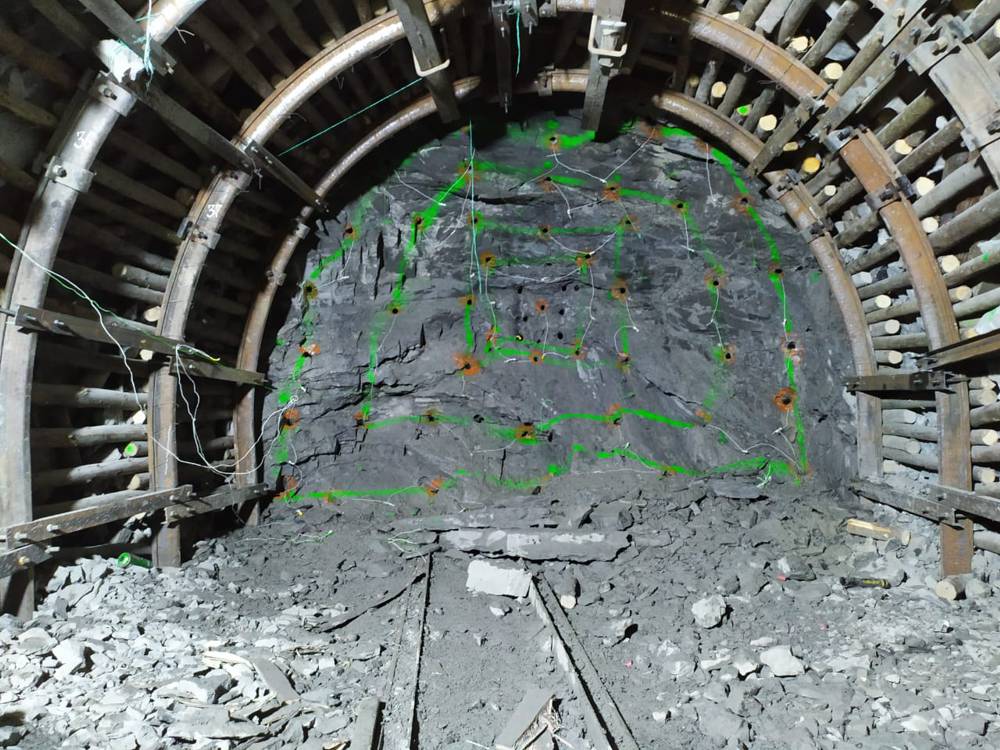

In the pursuit to challenge and solve the disadvantages of conventional products and drive sustainable global change, the business and scientific research and development team are unrivalled in the advancement of the technology which notably is a revolutionary gamechanger in this industry. AutoStem™ rock breaking cartridges are supplied to quarries, mines, and civil construction and demolition sites globally.

Traditional conventional explosives are divided into two categories, high and low explosives, the AutoStem™ rock-breaking system combines the best of both categories and introduces itself as a third category explosive product to be used in both primary and secondary blasting applications, selective sensitive or restricted areas, in both civil and mining applications or groundwater and aquatic environments.

The innovation of AutoStem™ is achieved by combining the benefits of delivering high energy to rock with a power factor greater than conventional high explosives though with the slower burn speed of low explosives. The benefits achieved include, although are not limited to, all-around safety improvements, the avoidance of harmful shockwave consequences and vibration effects, flying debris, and toxic contaminants. AutoStem™ products are non-detonating, meaning that the product action is that of deflagration and shearing of rock rather than the conventional counterpart product which detonates and pulverizes rock.

In effect, the AutoStem™ product does not amount to overbreak and with low vibration characteristics protect surrounding rock and ground strata adding the benefit of better blasting control, and fragmentation. In mining, there is no loss of commodity and yields are sustainably higher due to fewer fines and dust and improves ventilation efforts in underground operations.

No explosive accessories are required, thus the use of detonators and detonator transportation, storage or handling is avoided. AutoStem™ products are also dual self-stemming™, therefore there is no need for the blasters to add gravel, stemming, or tamping material. This improves efficiencies in safety, time, and cost. All AutoStem™ cartridges are categorized as Gas Generator P2 – 1.4s which enables AutoStem Technology to transport and store its products internationally with fewer restrictions.

In a challenging and transformative world, social and environmentally responsible companies aim to reduce any damaging effects on society, safety, and the environment from explosives use and blasting processes. The negative consequences and far-reaching implications this has had on the environment and society call for innovative world-improving products and solutions. One of the major risk factors results from theft and the use of explosives by anti-social elements for malicious intent.

When transported, AutoStem™ does not require a security escort as the product cannot self-ignite due to the novel safety switch™ technology and cannot possibly be used for destructive or malicious intent. The AutoStem™ product is so safe that it can be transported by air courier and stores safely with the added benefit of a longer shelf life than conventional explosives products. Given the characteristics of conventional explosives and the impact on global security, safety, and environment, the AutoStem™ innovation, in contrast, has inherent safety and impact control mechanisms built into the product features and characteristics that are deemed generic in safety, health, environment, and risk as well as Corporate ESR planning and compliance management.

When considering explosives use, there are two trains of thought when it comes to social and environmental controls, safety, security, and environmental impact responsibility. The first being merely, “monitoring compliance” requirements and the second, “planning to comply,” which is often overlooked, although most relative in a world that demands improvement in corporate responsibility and sustainability. In the conventional sense, “monitored compliance,” is primarily focused on vibration and air-blast caused by explosives whereas the non-conventional compliance benefits, features, and characteristics of AutoStem™ are generic to, “planned compliance” and built into the very product.

When it comes to product choice, good governance, safety, and responsibility amidst your blasting operations is your company merely monitoring or also planning to comply?

AutoStem™ is notably the best product option for the environment and social security and safety in transporting, storing, handling, and use when it involves mining, commercial, and or civil blasting. AutoStem™ is internationally accredited by all regulatory bodies for use in hard material excavations, ground, or concrete works, and structure demolitions and can be used in proximity of communities or infrastructure, above or below ground, and underwater without causing contamination or damage.

In conclusion, the AutoStem™ Solution ticks all boxes, the value addition this high-performance and innovative rock-breaking product adds to blasting operations suggests good governance whilst offering optimal innovative improvements in production and efficiencies in the management of blasting projects and overall outcomes.