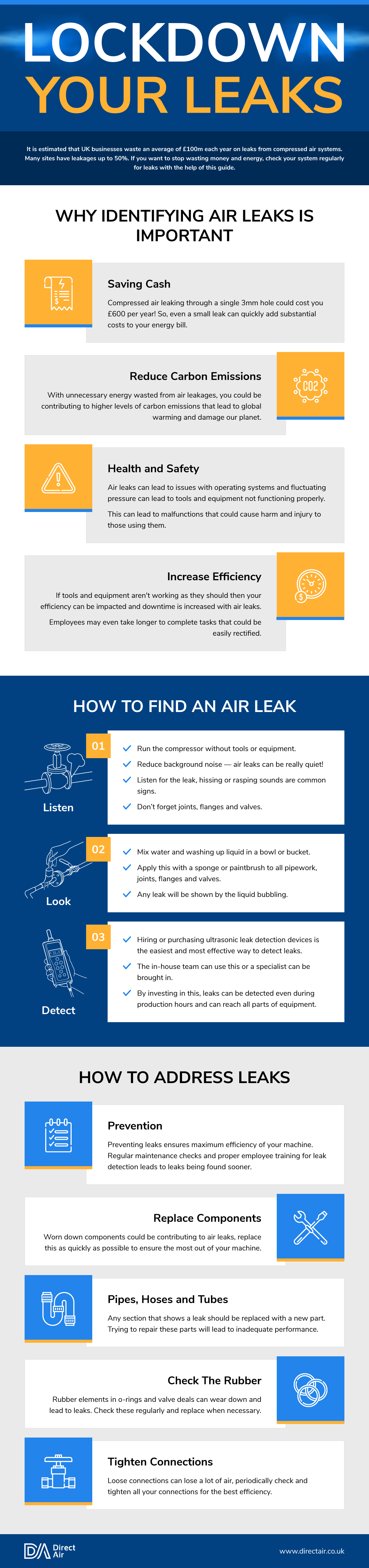

Air Leaks cost UK business £100m every year

Across UK-based businesses, it is estimated that a staggering £100m is lost every year through air leaks.

Wasted energy isn’t just hitting the wallets of the industry but also contributing to carbon emissions and a negative impact on our planet.

A hole in equipment as small as 3mm could contribute to a loss of over £600 per year to one business alone. Alongside this, an air leak could lead to underperformance of equipment and potentially impact the manufacturing processes.

Health and safety should always be the top priority in the workplace, while escaping air may not seem like a hazard, it can actually pose a risk to employees. Fluctuating pressure from air leaks can cause tools and equipment to malfunction without warning, leading to harm to the user and those around them.

That’s why Direct Air is on a mission to make sure everyone in the industry knows how to prevent and detect air leaks.

Detecting Air Leaks

Without a visual for what is leaking, it can seem impossible to find an air leak without prior knowledge.

By following the right steps, businesses can be on their way to saving costs.

1) Listen For Leaks

- Turn off all equipment and tools

- Reduce any background noise, it’s ideal to perform this out of manufacturing hours

- Listen to all areas and be conscious of any hissing or rasping sound

2) Look For Leaks

- Create a mixture of soap and water

- Using a sponge or paintbrush, apply this mixture to all pipework, flanges, joints and valves

- If there is an air leak, this will be made apparent by bubbling liquid

3) Professional Detection

- Ultrasonic leak detection devices can be purchased or hired

- These can be used by an in-house team or a hired professional

- They are the most effective way to detect leaks

Preventing Air Leaks

Prevention is the best course of actions to ensure maximum efficiency and safety to equipment.

- Schedule regular maintenance checks of equipment and train all floor staff in the detection of air leaks

- Replace worn down components as soon as possible, even if they appear to be working sufficiently

- Cracked or damaged pipework should be replaced immediately, do not attempt to patch these as a permanent solution

- Rubber components wear down quicker than others but are typically hidden, check these as often as possible.

- Lose connections allow air to leak easily and are the easiest way to rectify a leak. Tighten these often.

Air leaks may seem daunting to address at first, but you are made aware of how straightforward it really is to address them, there is little excuse not to.

It’s time for the industry to step up, help reduce carbon emissions, save money and keep employees safe.