PERI InSite Construction Pressure Monitoring wins major awards

The PERI InSite Construction (ISC) Pressure Monitoring Set for formwork systems has won the British Construction Industry Award for Product Innovation of the Year 2021 as well as being recognised in two categories at the Festival of Innovation and Technology 2021.

The digital solution helps to optimise the concreting process on the construction site, thus saving time and cutting costs.

The PERI InSite Construction (ISC) Pressure Monitoring Set has won the Product Innovation of the Year Award at the British Construction Industry Awards (BCIA). Known for having the most rigorous adjudication process in the construction industry, the award is given to a product or project in the field of design or construction that constitutes a project-specific solution or improvement.

Innovative strength driven by teamwork

“The award demonstrates PERI’s innovative power to achieve great progress in productivity and safety for our customers with a holistic, digital solution,” says Thomas Imbacher, Managing Director Innovation and Marketing of the PERI Group. “It is a great success of the whole team and the result of a flexible, agile collaboration between our Swedish development team in Gothenburg, the Connected Concreting team of Digital Products & Services and our colleagues in the UK.”

Optimised concreting process with PERI InSite Construction

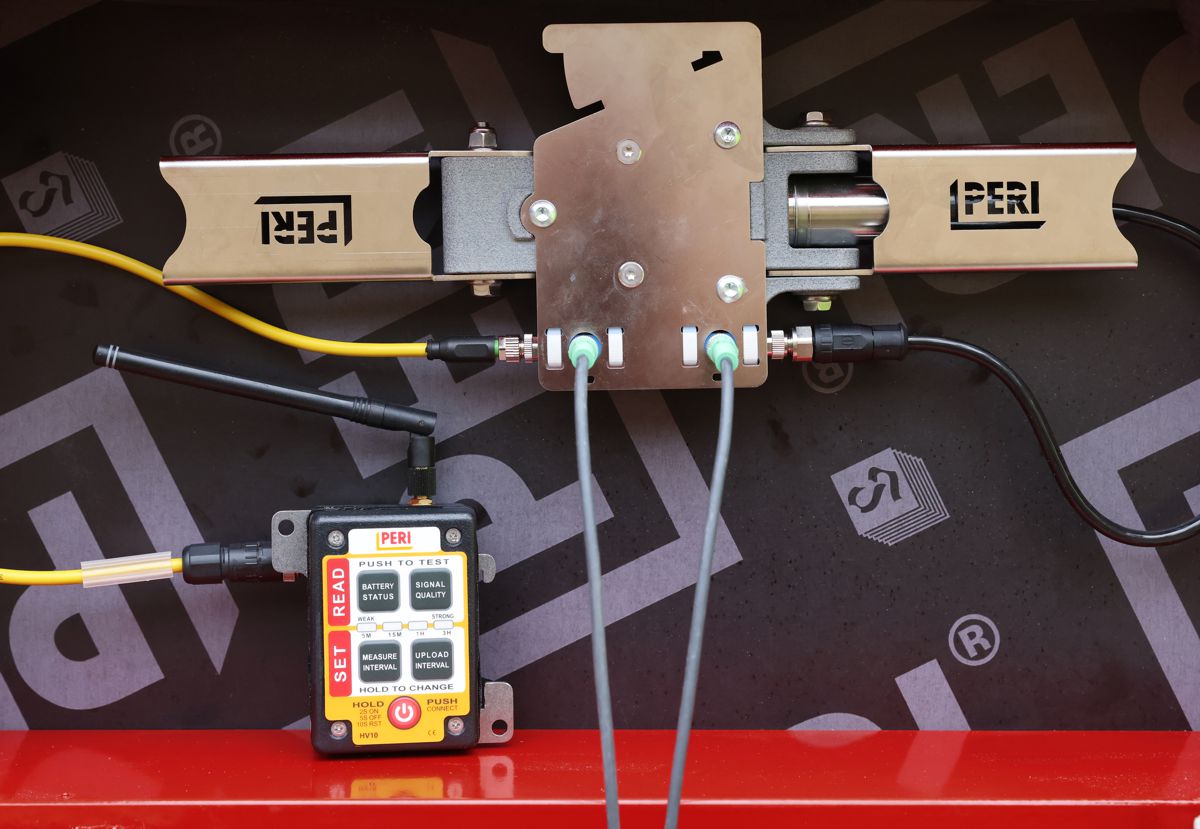

The PERI ISC Concrete Pressure Monitoring Set measures the pressure that the concrete exerts on the formwork and then transfers the data to the ISC Web Application.

This allows the concrete pressure to be monitored in real time and the concreting speed to be optimally adjusted. This leads to a safe concreting process and optimised utilisation of the formwork.

Improved concrete quality thanks to real-time analysis

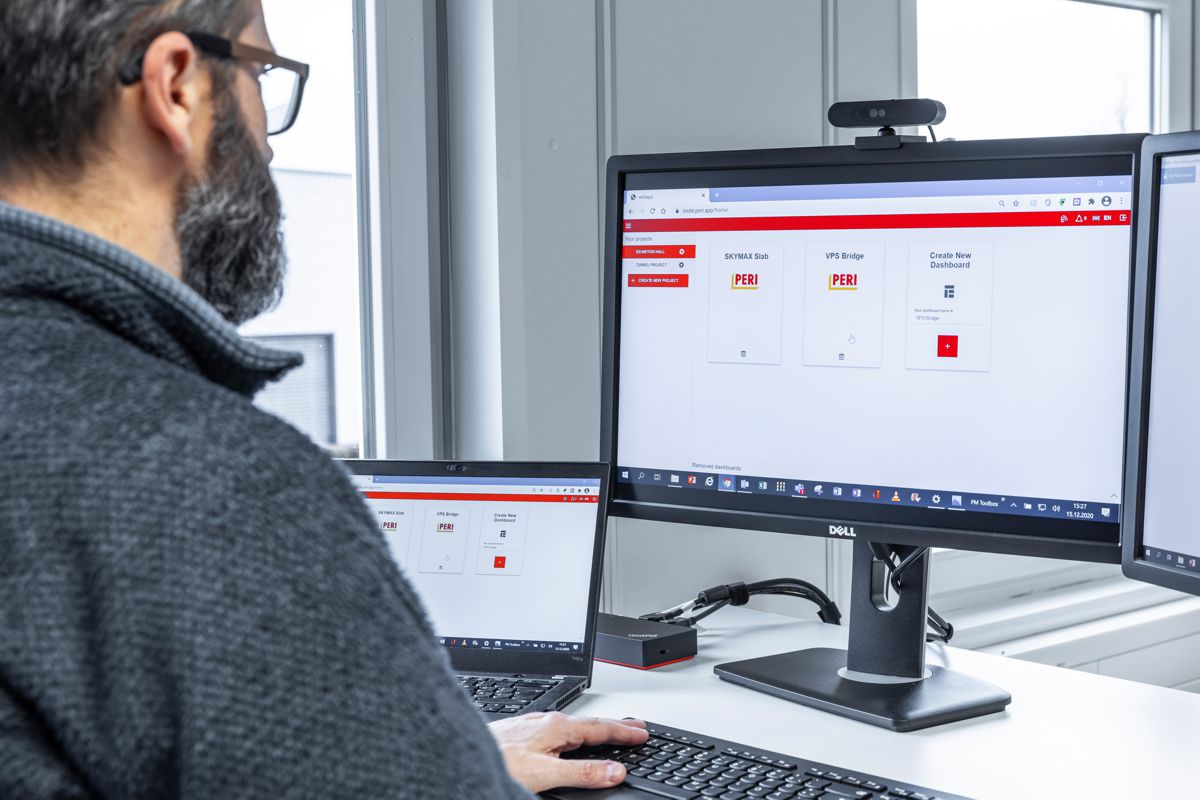

The user can analyse the collected data with the ISC Web Application at any time and from any location and make data-based decisions. This can lead to a higher concrete quality and reduce the risk of formwork breaks and deformations.

The ISC Web Application has an intuitive interface that provides users with a real-time overview of the concreting process and concrete pressure. The dashboard of the application can be configured according to individual customer requirements.

The user is also automatically notified when pre-defined values are reached. In addition, another notification and blog function facilitates transparent communication within the project team. The amount of effort involved in documentation procedures is minimised due to the fact digital reports on completed concreting processes can be generated easily.

Ease of use

Determining the concrete pressure with PERI InSite Construction is very straightforward. The system is compatible with all formwork systems and constitutes a standardised system for the entire concreting process.

Due to the fact that it operates over the mobile communications network, the user benefits from broad network coverage, which minimises costly downtime and ensures continuous data transmission. The ISC Sensor Node is charged efficiently in the ISC Technical Cabinet or directly via the mains supply.

Successful and award-winning deployment in the UK

In the UK, the system has already been used in major projects such as Hinkley Point C and the Regent Street Flyover in Leeds. “We were able to maximise the hourly utilisation rate of the formwork and complete the concreting process in 9.5 hours instead of the theoretical 32.5 hours,” reports Dave Robinson of CIDON Construction after using the system for the Regent Street Flyover project – a 60 percent increase in efficiency. 50 percent of the improvement was down to the use of PERI InSite Construction, which also led to direct cost savings.

The PERI InSite Construction Pressure Monitoring Set received awards in two categories at the Festival of Innovation and Technology 2021 for the role it played in this project. The PERI technology won through in the “Best Use of Technology: Productivity” category for increasing efficiency by monitoring the formwork pressure. PERI ISC was also recognised in the category “Best Use of Technology: Intelligent Data Collection”.