Johns Hopkins University creates shock-absorbing lightweight super material

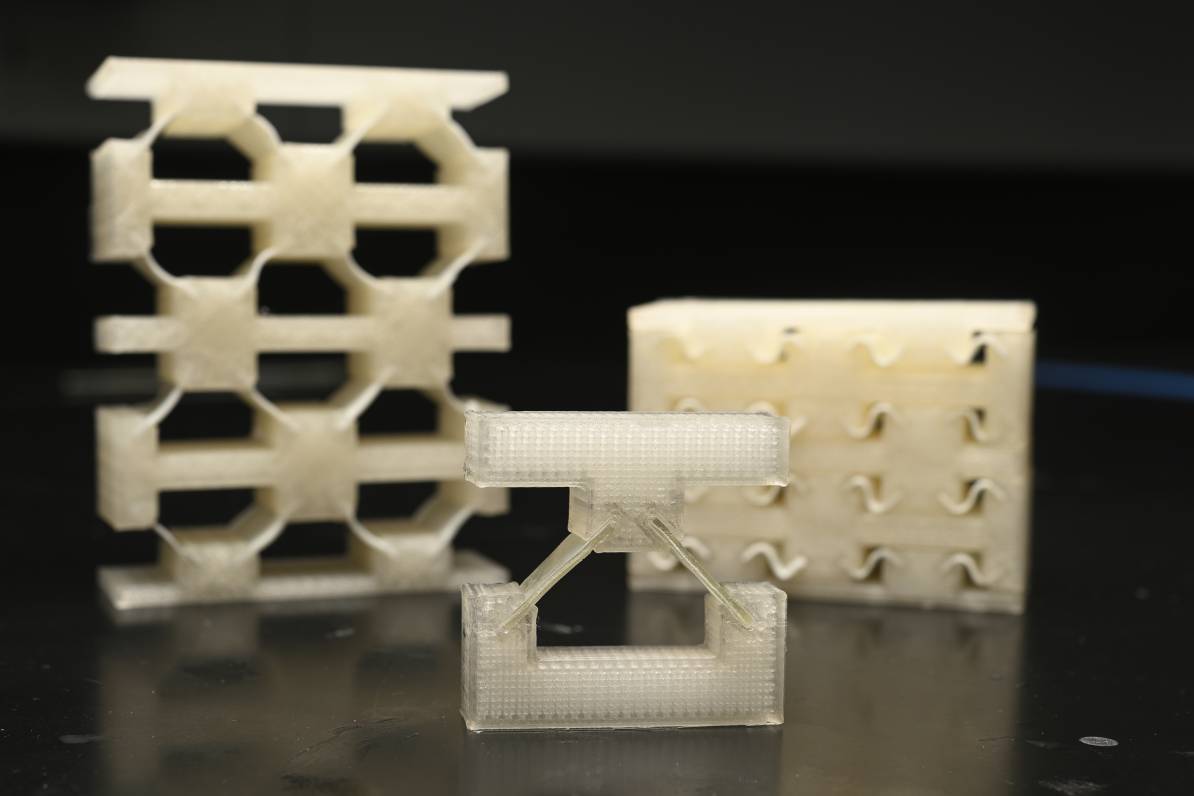

A team of Johns Hopkins University researchers created shock-absorbing material that protects like a metal, but is lighter, stronger, and reusable. The new foam-like material could be a game-changer for helmets, body armour, and automobile and aerospace parts.

“We are excited about our findings on the extreme energy absorption capability of the new material,” said senior author Sung Hoon Kang, an assistant professor of mechanical engineering. “The material offers more protection from a wide range of impacts, but being lighter could reduce fuel consumption and the environmental impact of vehicles while being more comfortable for protective gear wearers.”

Kang, who is also a fellow at the Hopkins Extreme Materials Institute, wanted to create a material even more energy-absorbing than current car bumpers and helmet padding. He noticed the typical materials used for these critical protective devices don’t perform well at higher speeds and often aren’t reusable.

The research team increased the material’s ability to withstand impact by using high energy-absorbing liquid crystal elastomers (LCEs), which have been used mainly in actuators and robotics.

During experiments to test the material’s ability to withstand impact, it held up against strikes from objects weighing about four to 15 pounds, coming at speeds of up to about 22 miles per hour. The tests were limited to 22 miles per hour due to limits of the testing machines, but the team is confident the padding could safely absorb even greater impacts.

Kang and his team are exploring a collaboration with a helmet company to design, fabricate, and test next-generation helmets for athletes and the military.

The results appeared in the journal Advanced Materials.

The research is supported in part by funding from the Army Research Office and the Johns Hopkins University Whiting School of Engineering Start-Up Fund. The Johns Hopkins research team also included Lichen Fang, a former graduate student; Thao (Vicky) Nguyen, a professor of mechanical engineering; Beijun Shen, a graduate student; Seung-Yeol Jeon, a former postdoctoral researcher at the Hopkins Extreme Materials Institute; and Zeyu Zhu, a former graduate student; and Nicholas A. Traugutt, and Christopher M. Yakacki, both of the University of Colorado Denver.