Sintering Solid Waste could reduce Excavated Soil and Rock

Urban construction, especially the ongoing large-scale expansion and utilization of underground space, has resulted in massive excavated soil and rock from buildings and subways. A novel solution suggests sintering utilization is a feasible method to recycle solid waste to construction products from the perspective of technology, environment, and policy through qualitative and quantitative methods.

This study was published by Tsinghua University Press on 19 May 2022, in Circular Economy. (DOI 10.1016/j.cec.2022.100007)

Their paper discusses the feasibility of excavated soil and rock environmental-friendly sintering technology and aims to explore the utilization of sintering from the technical point of view, environmental protection restrictions, and governmental policy levels. Specifically, the case object of this study is excavated soil and rock generated in Shenzhen, China.

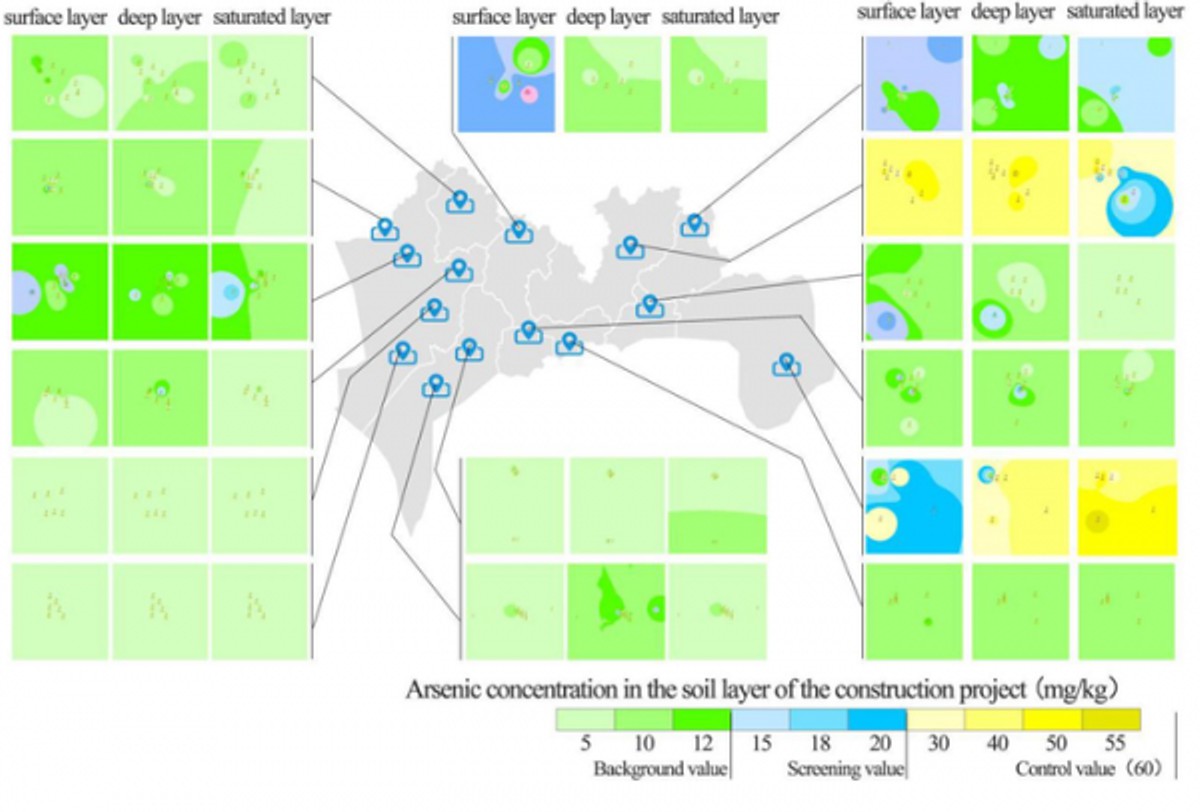

First, the technical evaluation aims to determine whether the soil conditions of excavated soil and rock meet the criteria of relevant standards and technical sintering utilization specifications. The investigation of excavated soil and rock samples in Shenzhen reveals that the soil types in each administrative region of the city are complex and diverse, and the excavated soil and rock of high-content clay produced by the existing construction project in Shenzhen (2020) is estimated to be 37.3%, which can be recycled as the sintering raw materials.

On this basis, we can estimate the entire amount of high-content clay that can be used as sintering raw materials in Shenzhen is close to 27 million m³. If some fired brick and tile plants operated in Shenzhen under the encouragement of competent authorities, using 27 million m³ of clay-rich excavated soil and rock to sintered products instead of traditional disposal will save nearly 270 million yuan of disposal cost.

Researchers of this study also collected the actual emission data of some representative fired brick plants of excavated soil and rock (or co-combustion) as sintering raw materials in China, and the actual air emission concentration of domestic factories can meet the “Emission Standard of Air Pollutants for Brick and Tile Industry (GB-29620-2013)”, which showed that there was no implementation obstacle from the environmental perspective of sintering excavated soil and rock.

Finally, at the policy level, mainly from the perspective of national and provincial policies and systems, the sintered brick industry belongs to the encouraged industry. It is feasible to promote excavated soil and rock sintering utilization at the national and municipal policy levels.