bauma explores the Digital Construction Site

A number of barriers standing in the way of digital construction sites—particularly the lack of data standards—must be eliminated. Industry experts will explore the challenges and solutions during bauma TALK.

The webinar series bauma TALK acts as a base of information for bauma 2022 and delves into the key topics of the construction-machinery trade fair that will be held from October 24 to 30 in Munich. The latest presentation and discussion event was held on May 24 and focused on the digitalization of construction sites. In particular, the conference highlighted the key role that machinery data is already playing in efficient construction practices—from predictive maintenance to smooth transport and logistics operations and many other construction site processes.

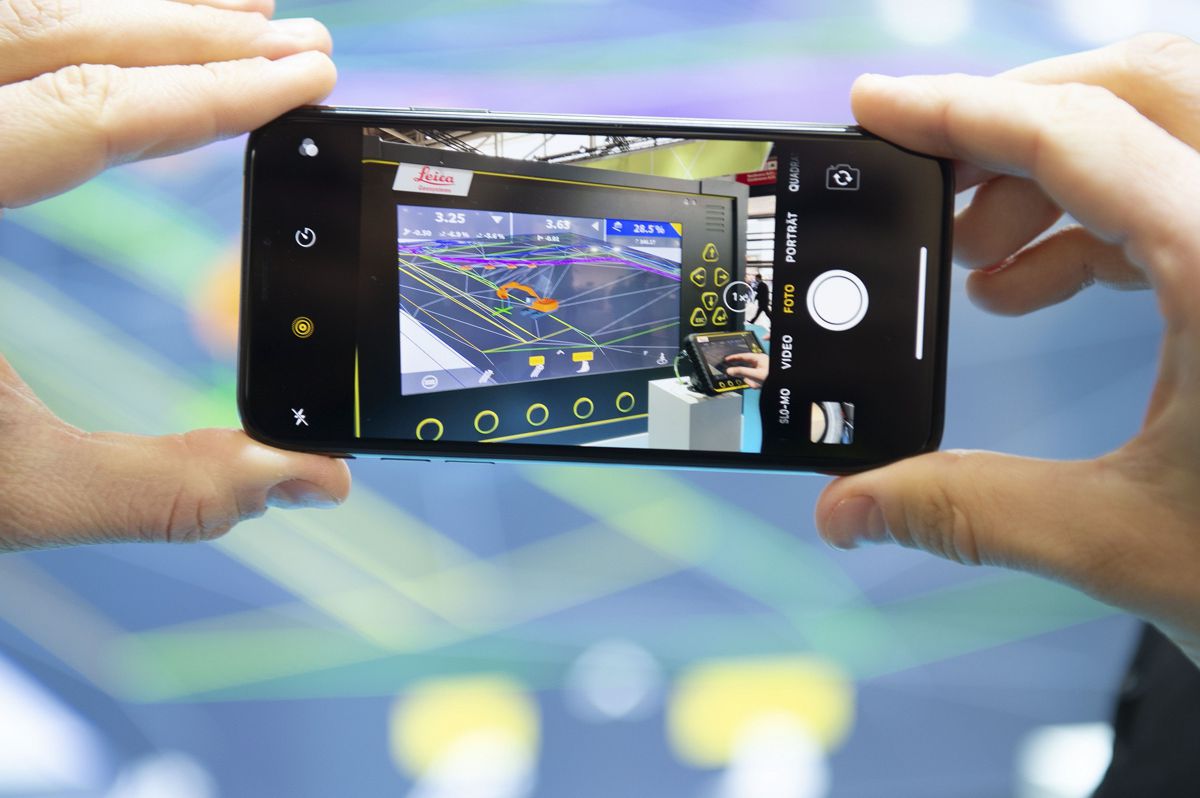

Alexander Mozer, the team leader of machinery digitalization at the major German construction company LEONHARD WEISS, discussed some of the technologies involved: “In terms of CO2 emissions, telematics can provide us with important information about the fuel consumption of every piece of machinery. Digital position information helps reduce search times, and automatically collected operating hours are an important parameter used in maintenance planning and invoicing.”

But the jobs of integration and management are complicated by several factors: the different interfaces used by various manufacturers, sensing accuracy and intervals as well as data interpretation. “The simple job of adding or deleting a piece of machinery to or from a system can end up being a very time-consuming process,” Mozer says.

MiC 4.0: working on uniform digital communications

As a way of clearing these fundamental hurdles, the German Mechanical Engineering Association (VDMA) and the Main Association of the German Construction Industry (HDB) set up a working group called Machines in Construction 4.0 (MiC 4.0) at bauma 2019. “Our goal is to develop a uniform, cross-manufacturer and machinery-independent communications form for the entire construction process,” said Michael Tonke, a member of the Committee for Construction Machinery Technology and Construction Logistics at the construction industry association. At the moment, 105 members from seven countries are developing sub-aspects of MiC 4.0 in 31 working groups.

New bus solution at the data interface machinery/accessory tools

Construction machinery is far from the only thing that is getting smarter. Digitalization of tools that can be combined with them is progressing as well. “Good solutions are already being widely used in the hydraulic and electric interfaces to accessory equipment. But the job of facilitating cross-manufacturer data transmissions between components has run into some massive problems,” said Katharina Schick, a project engineer at Liebherr-Hydaulikbagger GmbH. In response, a MiC 4.0 working group has been developing an open, manufacturer-independent data interface—the MiC 4.0 bus—over the past two years, Schick said. “We conducted some promising tests with it on an excavator in April 2022,” she said.

A demonstrator of the new interface will be presented during bauma at the MiC 4.0 booth in the LAB0 innovation hall. The interface protocol will be released by the German Mechanical Engineering Association after the trade fair has concluded and the final work has been completed.

Connectivity module links to the construction-site control system

Jürgen Weber, a doctor of engineering who holds the chair of fluid-mechatronic system engineering at the Technical University of Dresden and heads the association research project called Bauen 4.0 (Construction 4.0), has found that non-homogeneous fleets of machinery with their various data solutions are far from the sole cause of problems related to the development of the vision of a digital construction site. “In many cases, there is simply no mobile Internet available. The required network coverage does not exist,” the expert said. As a potential solution, he presented a concept that combines a local network with a construction-site control system.

In this solution, programs that can perform such jobs as record and analyse all machinery data as well as simulate construction processes in real time run on a server. “The machinery must be outfitted with a connectivity module that enables it to exchange data with the central construction-site control system and with other machines,” Professor Weber said. A platform-independent OPC Unified Architecture is used as a standard to facilitate communications and networking.

Other work is under way to close the gap separating research from the market readiness of the digitalized construction site of the future. As part of these efforts, the non-profit company Construction Future Lab GmbH was recently set up in the eastern German city of Görlitz to serve as a neutral partner for interested companies and research institutions.

You will find a recording of this edition of bauma TALK and all other previous segments here. The next webinar will explore the topics of “Mining—Sustainable, Efficient and Reliable” (June 29, 2022) and “The Road to Zero Emissions” (September 14, 2022).