New Litz Wire electric motor winding technology cuts e-motor losses by 25 percent

hofer powertrain marks another milestone in developing future-proof drives with the successful patent of its new Form Litz Wire winding technology.

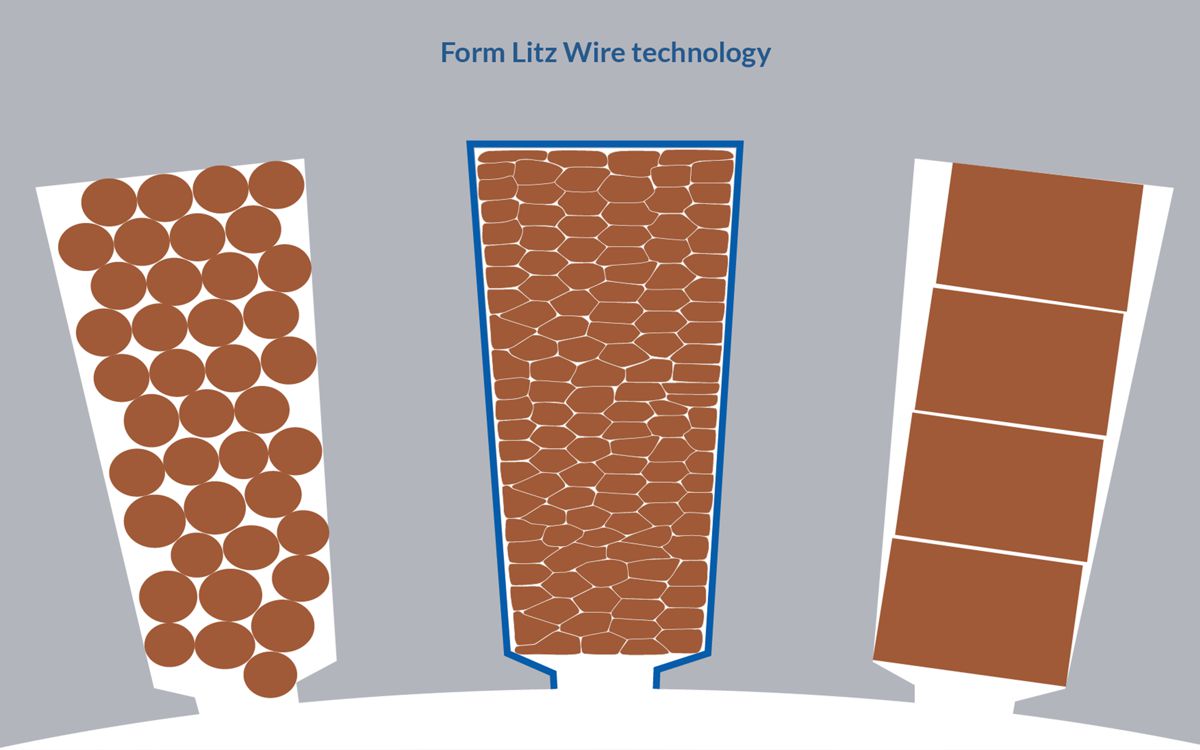

This new technology offers significant economic, efficiency, and sustainability benefits, making electric motors smaller and lighter while maintaining the same high performance as its predecessors (the Pull-In and Hairpin winding).

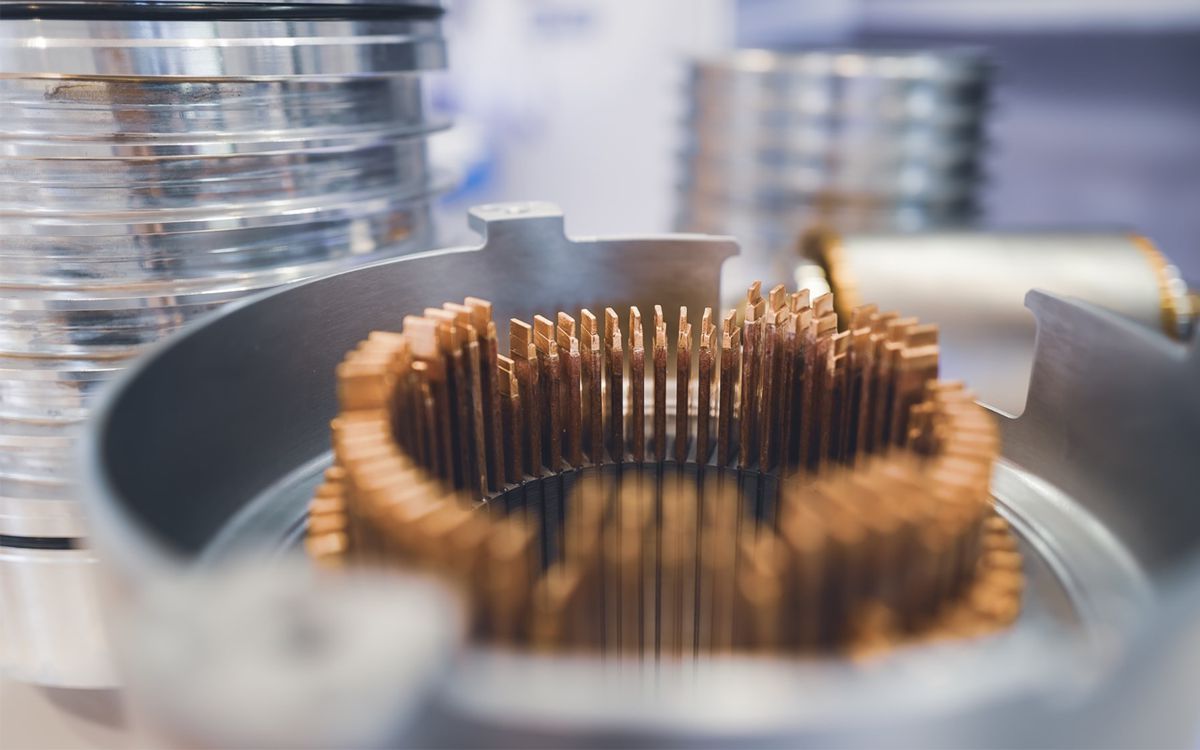

Form Litz Wire consists of parallel wires packed into a highly compact form, ensuring a high filling factor. It enables effective integration with various cooling systems, thus reducing energy losses to a minimum. Numerous tests confirm electric motor energy losses are reduced by up to 25%, positively affecting the entire system and resulting in continuous high output for an extended driving range.

hofer powertrain is making the automotive industry more sustainable through its innovative powertrain solutions. It focuses on reducing materials in its stator, rotor, and housing designs. The quantity of copper, iron, and rare earth metals in its permanent synchronous motor (PSM) is substantially lower.

Form Litz Wire is also cost-efficient. In the near-term, manufacturing can use conventional Hairpin winding tools to achieve production with minimal industrialization effort. In addition, its robust design lends itself to consistent production quality control and offers scope for automation. hofer powertrain is directing its efforts toward large-scale production to maximize the economic benefits for its customers even further.

The new winding technology is suitable for electric and hybrid powertrains, from passenger cars and formula-class sports vehicles to trucks and commercial vehicles. Besides technology licenses, hofer powertrain offers ready-made solutions and supports its customers as a development and manufacturing partner from conception to production and beyond.

“Achieving multiple efficiency and sustainability goals in powertrains with our technology makes us particularly proud,” Johann Paul HOFER, CEO of hofer powertrain.