Manufacturing a Liebherr Material Handling Machine

At bauma 2022, Liebherr will be presenting the LH 150 M Port E handling machine. It is specially designed for handling scrap and mixed cargo in ports and is equipped with an electric drive and a new, mobile gantry undercarriage.

How does such a product become reality – which work steps and requirements have to be taken into account in the process?

Step 1: Brainstorming

As Area Sales Manager, Peter Johannsen is responsible for markets such as Asia and Turkey, as well as for major projects such as the LH 150 M Port E. Since customers often have individual requirements, listening is Peter Johannsen’s top priority. Understanding customers’ tasks and their logistics and offering the right solution for them – this is where many years of experience and an eye for the bigger picture come into play.

Based on the specific customer requirements, the team configured an LH 150 with rubber tyres and electric drive. To give the machine the necessary freedom of movement, there is a choice of different cable feeds. With the mobile gantry undercarriage, the machine can cover longer distances without damaging the ground and is flexible in confined areas.

Step 2: Development

A development team at Liebherr takes care of the material handling machines for use in ports. Constantin Wegmann (centre) and his colleagues are the link between departments such as sales,

design and testing, production or customer service. He looks after the product from start to delivery: he checks the technical feasibility, draws up schedules and ensures that the drawings and parts lists are completed on time.

For the LH 150 M Port E, the challenge was the technical implementation of the new, mobile gantry undercarriage.

Step 3: Design

As a design and development engineer in the undercarriage department, Joachim Koßmann is “the man for new developments”. As the project manager responsible for the system, he creates the rough contour of the undercarriage in CAD, which includes the longitudinal beam, pillars and centre section. He also approves the final designs. He clarifies the functionalities of the machine and links existing components with new calculation models. In the process, he is in contact with departments such as hydraulics, electrics or customer service.

With the LH 150 M Port E, Joachim Koßmann is accompanying an exhibit to bauma for the third time in a row.

Step 4: Manufacturing

All individual parts of the machine are then manufactured according to strict Liebherr quality standards. Welders, for example, join the large steel components together. As these have to bear large loads and are subjected to very high and dynamic stresses, particularly well-trained specialists are required.

Strict testing steps ensure that, among other things, the welding seams are precisely executed. This is how they guarantee the reliability and durability of the LH 150 M Port E.

Step 5: Assembly

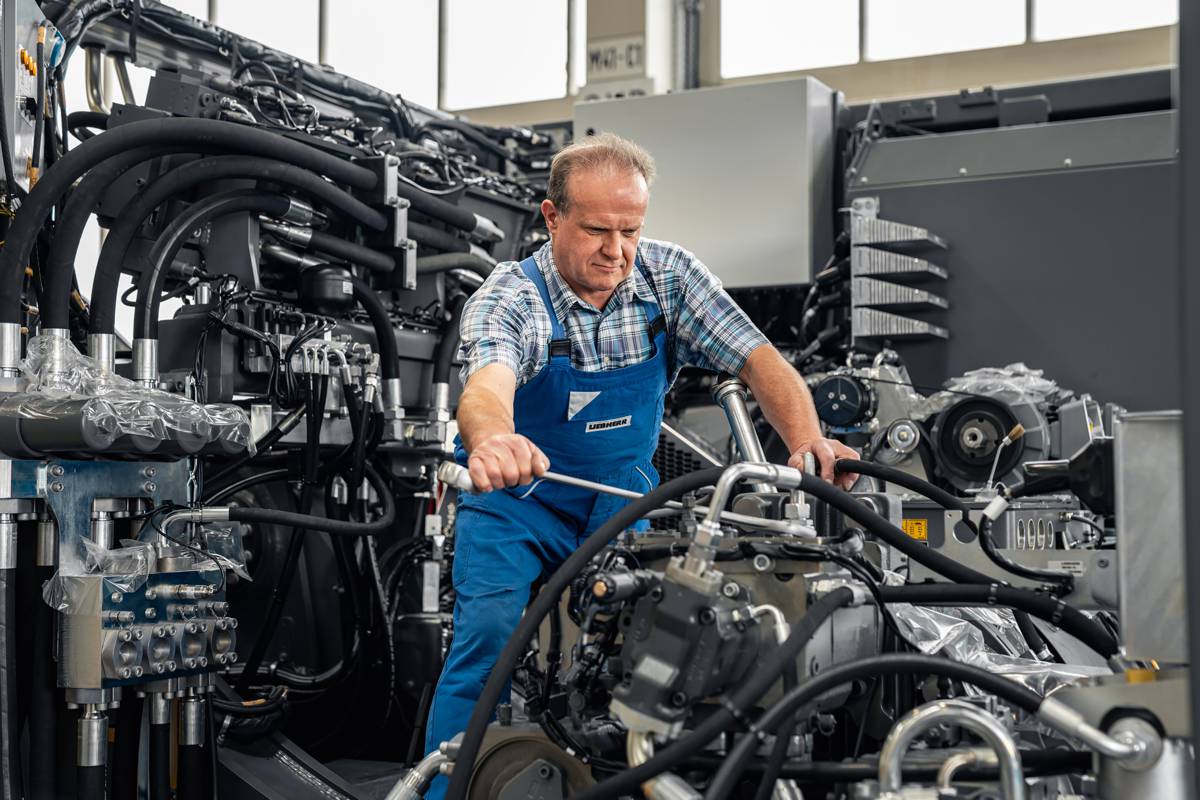

Final assembly of the LH 150 M Port E takes place at the factory in Kirchdorf. Well-tested and high-performance components are used. A high proportion of key components were manufactured in Liebherr factories.

Here, Viktor Maier assembles the drive group of the LH 150 M Port E. It is “the heart of the machine”. Timing is crucial at this stage: the individual parts must be on site at the right time so that assembly can proceed smoothly.

Step 6: Set-up and testing

Once the machine has been assembled, commissioning and function tests follow. Jochen Sailer (left) measures and checks the complete range of functions: all components and parts are parameterised, adjusted and their functionality tested in interaction with one another.

The machine is usually ordered with a particular customer specification. The LH 150 M Port E for Bauma, for example, is equipped with a hydraulic, multi-adjustable driver’s cab.

Only after a successful function and completeness check is the machine is dismantled.

Step 7: Labelling as electric drive technology

Although the Kirchdorf factory is steadily expanding its range of electric drive series, the blue sticker is being used here for the first time.

The additional product labelling denotes electrically powered machines as a uniform identification symbol in the group of companies.

The LH 150 M Port E can produce a total system output of 614 kW thanks to the 400 kW electric motor and the ERC system.

The machine’s electric drive concept is low-maintenance, low-noise, emission-free and can thus be operated in an environmentally friendly manner.

Step 8: Logistics

Jochen Schneider coordinates dismantling in Kirchdorf, transport to Munich and assembly of the LH 150 M Port E at Bauma. In Kirchdorf, the machine’s handle and boom are dismantled first.

Then the driver’s cab is dismantled, the superstructure is lifted down and the undercarriage is disassembled. The team then prepares the individual parts of the machine for shipment. Ten trucks are needed to transport the individual parts to Munich. In some cases, heavy transportation is necessary – such as for the 60-tonne superstructure with cabin lift or the over 17-metre-long boom.

The challenge: parts that are dismantled last in the factory must first be assembled in Munich.

Experience the material handling machine up close. Liebherr will presents the LH 150 M Port E from 24 to 30 October at Bauma in Munich at stand 809-813.