Revolutionary 650kW continuous output motor designed for Hypercars

Globally renowned for the industry-leading power density of its electric motors, UK-based Helix has distilled its unique capability into a package it terms Scalable Core Technology (SCT). Building on the company’s proud automotive and motorsport heritage, SCT is available as three Product Levels – Stock, Configured and Custom – providing a clear pathway to production while matching powertrain requirements with the optimal level of customisation.

Standard products deliver high power off-the-shelf, allowing rapid access to Helix’s technology at minimum cost. Adapted from already-engineered solutions built, tested and delivered, configured products closely match more exacting customer requirements, while the Custom level delivers a product designed and developed to meet the most exacting specification through tailored SCT.

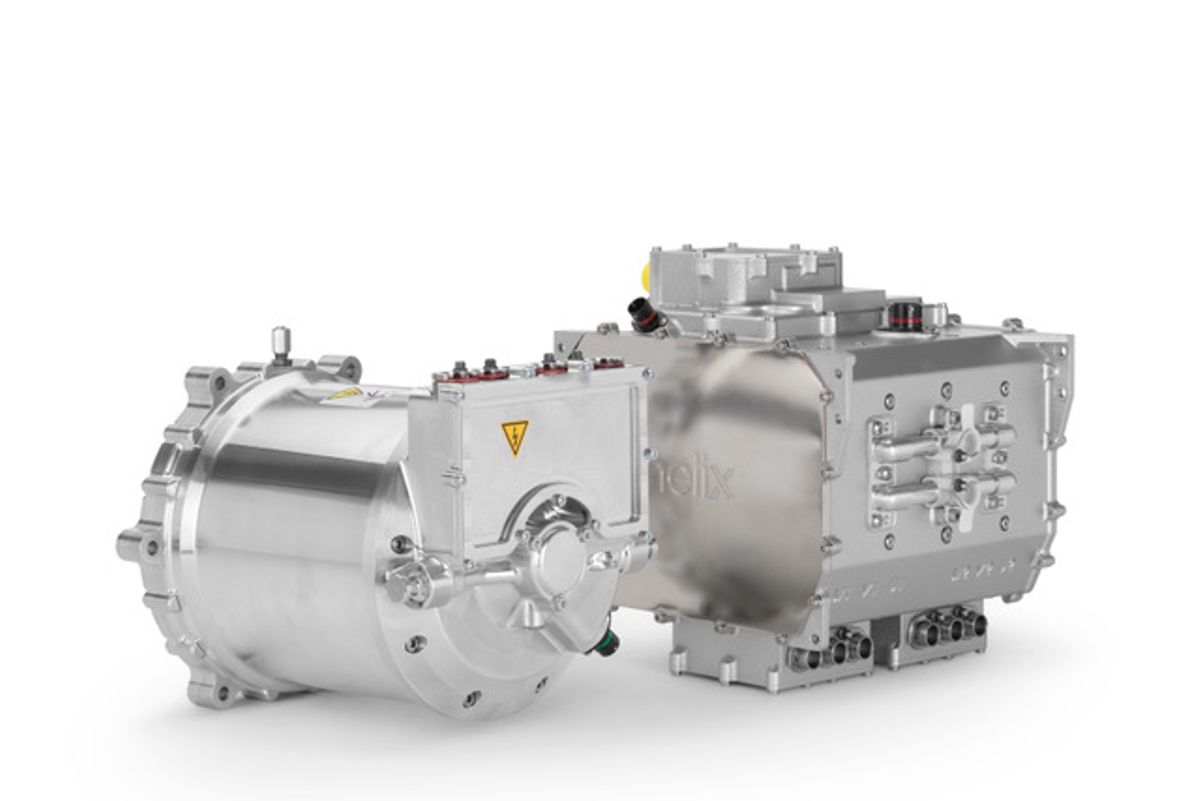

And then there’s Helix’s X-Division, keeper of the pioneering spirit that fuelled the company’s 25-year legacy, its passion for innovation and pushing performance beyond established boundaries. Clients bring their most demanding requirements to X-Division, where today’s impossible becomes tomorrow’s reality, a process recently proven with a hypercar motor project known internally as REB. Weighing only 28kg and capable of delivering 650kW of continuous power, this X-Division SPX177 product is the most powerful pure battery electric vehicle (BEV) motor the company has ever produced.

Derek Jordanou-Bailey, Chief Engineer at Helix, took overall responsibility for the project. His back story includes seven years at Integral Powertrain (IP), from which Helix evolved in 2022, before a stint at Mercedes-AMG HPP (High Performance Powertrains) working on F1 power units. He returned to IP, now Helix, in 2018.

Describing the project, he says: “It uses the ‘top end’ in materials and reaches back into our motorsport heritage. Our SCT is intended to deliver products that are tailored to customer requirements and easily manufactured in large production runs, but for REB the focus was on ultimate performance, accepting that the machine would be more demanding to manufacture in anything more than smaller batches. In those terms, it is like an F1 or Formula E unit.

“It’s small and weighs just 41kg, including the 13kg inverter. It is a 2x 3-phase motor, so its current is shared across two inverters, a necessary approach to meet the phase current demands at ‘normal’ DC voltages at this extremely high power level. Both the motor and inverter have extremely high power density. Six high-voltage cables connect the inverter to the motor, while an LV connector carries the various control signals.”

Helix developed the SPX177 product for an unidentified hypercar manufacturer and Jordanou-Bailey confirms a single motor delivering 650kW continuous will be installed in the vehicle. He notes that the motor delivered over 700kW peak on the test stand and ‘…it could potentially deliver more, we didn’t push it’. Even compared to the very latest, highly boosted internal combustion engines (the McLaren Artura, for example), the product weighs less than 1/7th for equivalent continuous power output, although Jordanou-Bailey concedes that the battery weighs a lot more than the IC engine’s fuel store. The battery pack is therefore the major item around which an electric hypercar is packaged, but low mass of this SPX177 product enables options in terms of where the motor is installed, helping optimise the car’s architecture for a low centre of gravity and cleaner aerodynamics, for example.

Unique architecture

Thinking back to the origins of the REB project and how it resulted in a product that was ultimately tested and shipped to the customer, Jordanou-Bailey recalls: “The customer told us what peak power they wanted and demanded a very high steady-state output. Right now, it is tricky to deliver sufficient energy to maintain that level of output, but in time it is likely to be possible and the customer wanted to ensure their flagship model was ready for that.

“We needed an architecture that minimises losses and the heat generated, especially at high-speed, and that meant quite a change in the way the motor was wound, since minimising resistance losses results in a very low inductance machine. The switching in the inverter can generate lots of noise and harmonics and this is more challenging with a low inductance motor. The software team did a great job developing a new way of controlling the phase currents in the motor.”

The result is a machine that ran extremely well and delivered more power than the team predicted. “I think much of that is down to our attention to detail,” Jordanou-Bailey continues. “We designed the motor and solved the control issues, while the onboard cooling was also very well thought out. We never considered ‘it’ll do,’ we looked at everything and did the best job we could. And this is the result, a motor that cools remarkably well and delivers record-breaking steady-state power.”

Considering the REB project team, Jordanou-Bailey says the original concept came from Luke Barker, one of four Helix directors. A team of no more than 12 engineers, including Jordanou-Bailey himself – although he asserts that he did ‘none of the heavy lifting’ – then completed the work, including the build, in little more than two years.

A proposal for an initial small ‘production’ batch is under way and, meanwhile, Helix is supporting the customer’s integration of the power unit into the vehicle. “Then there’ll be liaison with their software team, but since the motor and inverter are already paired, we expect it to largely be plug and play,” Jordanou-Bailey concludes.