Improving Train Safety with IoT-Based Remote Monitoring

Spanning 140,00 miles and supporting 167,000 jobs nationwide, the freight and passenger rail systems are a significant strength of the US economy. Of course, this nearly $80 billion-dollar industry is highly complex due to its sprawling infrastructure and sophisticated machines. And although trains are much safer than automobiles, they are not without risks.

The railway industry most commonly faces physical dangers in these forms:

- Derailments remain the most common risk, despite the industry’s best efforts, resulting in serious damage and loss of life

- Train collisions; while rare, can be particularly catastrophic

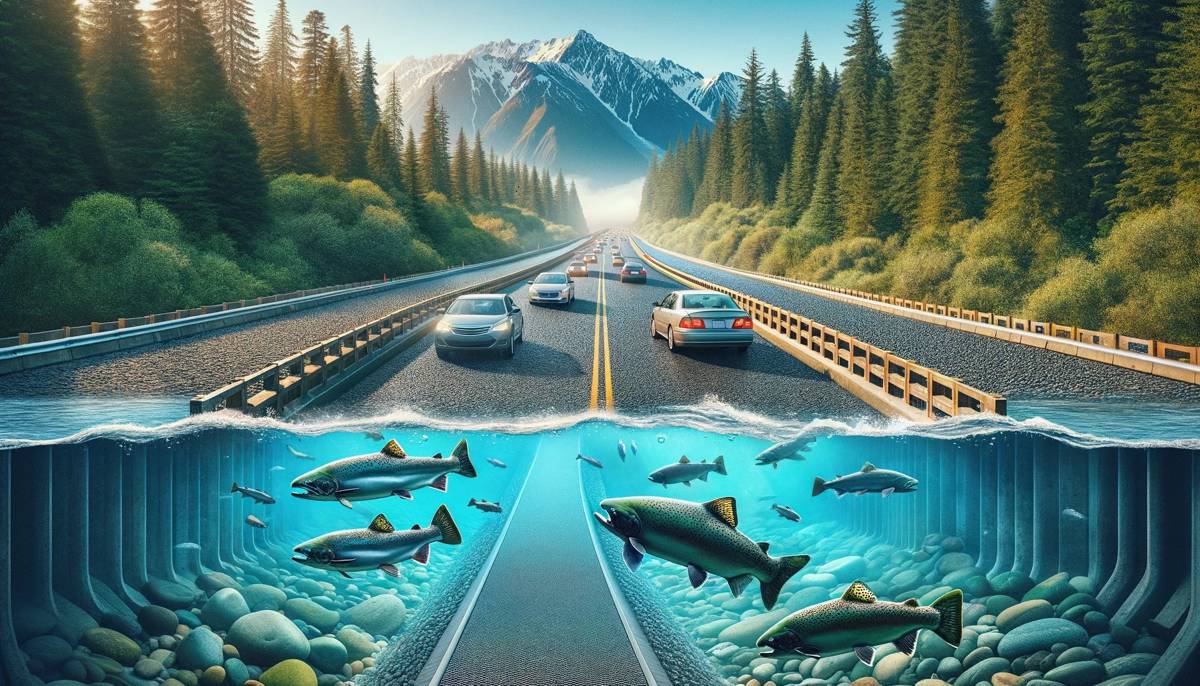

- Accidents from level/grade crossing, which usually occur when road users ignore the warnings of approaching trains

- The transport of dangerous goods such as chemicals, petrol, liquefied gasses and nuclear waste

As part of ongoing efforts to make railways more efficient, compliant and – most importantly – safer, rail companies are embracing Internet of Things (IoT)-enabled use cases like remote monitoring to safeguard cargo, equipment, and personnel.

What is Remote Monitoring?

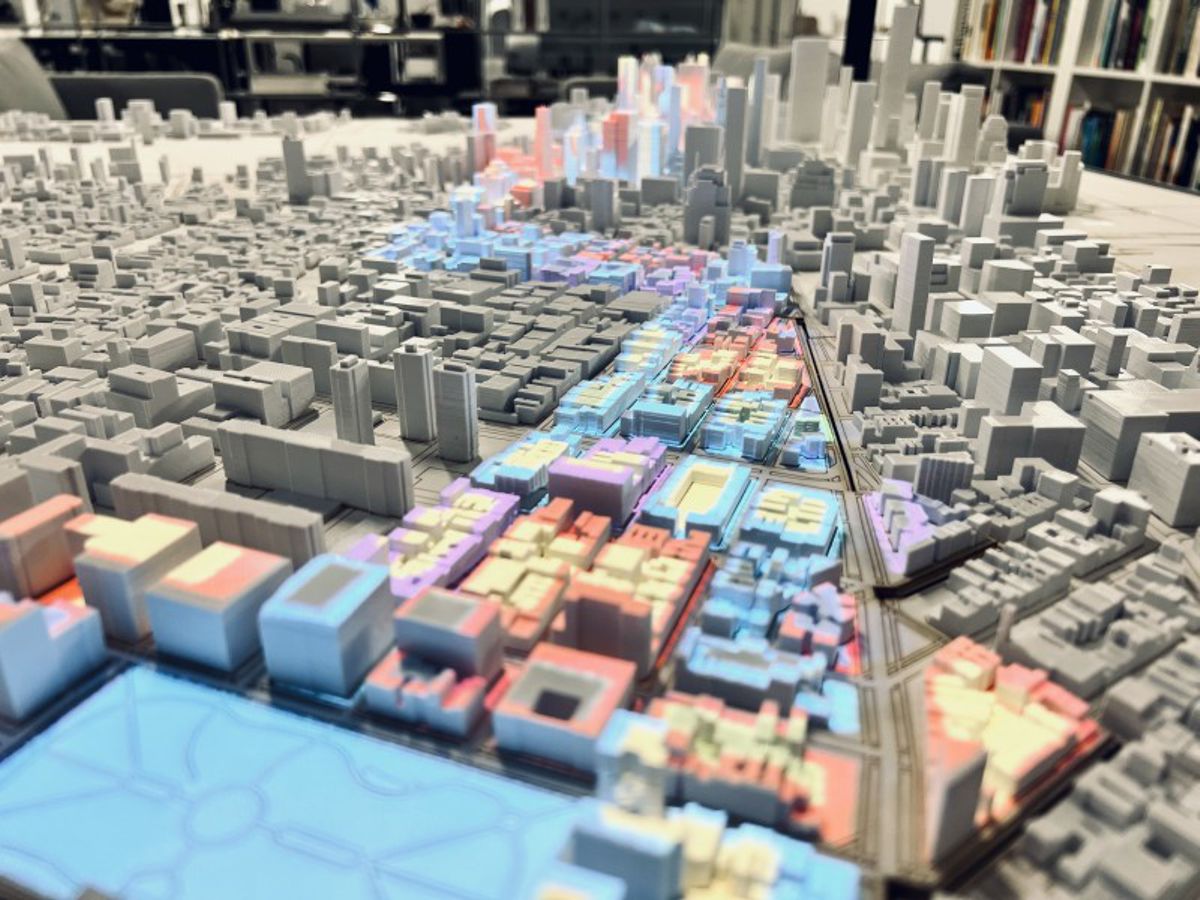

Remote monitoring is a process in which data collected from connected machines and systems provides railway decision-makers with real-time insights into critical assets, including performance indicators, environmental conditions, and any other irregularities. Specifically, remote monitoring solutions allow operators to remotely track different variables across their vast railway networks, from vibration and emissions to pressure and maintenance.

Insights extracted by remote monitoring systems give freight rail companies mission-critical visibility and timely alerts, enabling rapid responses to potentially hazardous situations. Notifications can also trigger automated procedures which rectify issues without human involvement, helping to prevent delays and other disasters.

While IoT sensors and devices are the bedrock of remote monitoring solutions, other technologies vital to supporting the secure and reliable tracking of trains and rail assets include remote site management appliances, Ethernet switches, purpose-built routers, remote terminal units, as well as cellular connectivity, cloud-based software platforms, and GPS solutions.

Remote Monitoring Use Cases in Railway Transportation That Increase Safety

With IoT-powered remote monitoring, railway transportation teams gain visibility of their dispersed systems and processes, allowing them to improve operational safety in several unique ways. For example, remote monitoring solutions can continuously measure the temperature of train tracks, notifying operators if areas are too hot or too cold. In particular, heat can cause tracks to expand, or get longer, which places excessive pressure on the ties, ballasts, and rail anchors, resulting in a higher probability of derailments.

Other safety use cases of remote monitoring in railway transportation include thief deterrents and weather alerts. In the former use case, freight rail companies can place sensors behind locked doors on their train compartments, rail yards, or other remote locations to track whether doors are opened or closed. Remote monitoring will trigger an alarm if there is unauthorized access, helping to thwart thieves from stealing expensive equipment or preventing forgetful employees from leaving important doors open at remote sites.

Likewise, by strategically placing monitoring devices throughout rail infrastructure, companies can support weather alerts that give managers ongoing updates, such as incoming snow, rain, or hailstorms, allowing them to take appropriate action to ensure the safety of passengers, cargo, and equipment. To that end, knowing a remote site is experiencing foul weather saves technicians the trouble of making repairs in unsafe conditions.

Unfortunately, plenty of trains still rely on trackside switches, which must be in the right positions to keep trains on the correct tracks and at safe speeds to prevent derailment. As such, operators must perform manual switch inspections because these switches are not “smart” (meaning they don’t connect to IP networks, IoT sensors, or dedicated energy sources). Of course, since emergency inspections or repairs can often put workers in unsafe situations, this model isn’t efficient or safe.

IoT-based remote monitoring systems, however, do away with these outdated switches, helping railway companies protect their personnel by automating inspections and routine maintenance. Automation capabilities are invaluable – especially when tasks require technicians to travel to locations that are too hazardous due to extreme weather conditions, the presence of harmful substances, or simply because the area is unsafe.

Ensuring Always-On Remote Monitoring

Despite the necessity of remote monitoring in railway transportation, these IoT-enabled solutions need network connectivity to function. Indeed, without a resilient network, all of the incredible benefits of remote monitoring are not possible.

Moreover, as freight and passenger rail companies continue to deploy IoT technologies at remote sites, the dependence on data generated outside the traditional data centre increases, requiring enterprises to support consistent resilience, scalability, and availability across their entire infrastructure.

By combining Smart Out of Band management with Failover to Cellular, railway companies can ensure resilient backup to their remote networks, enabling critical solutions like remote monitoring to continue operating, even during connectivity disruptions.

Smart Out of Band management infuses intelligence into the edge, helping railway operators more efficiently manage infrastructure at multiple sites while promoting advanced capabilities for automatic responses like identification and remediation. Additionally, Failover to Cellular provides continuous availability for remote networks with 4G LTE; plus, best-in-class solutions can integrate seamlessly with existing installs and get deployed quickly for new networks or branch locations.

Considerations Moving Forward

The US rail system (and, for that matter, the world’s) represents an exciting opportunity for innovation via IoT-based remote monitoring. Nevertheless, large swaths of rail infrastructure are outdated, necessitating extensive updates and installations to enable continuous remote connectivity.

At the same time, railway companies should not settle for any off-the-shelf network solution. They must vet providers thoroughly, prioritizing those partners whose technologies can bolster network resiliency, preventing small network events from snowballing into large-scale disasters.

Article by By: Tracy Collins, VP of Sales, Americas, Opengear.

Tracy has over 25 years of experience in leadership positions in the IT and Infrastructure industry. Prior to joining Opengear, Tracy led the Americas business for EkkoSense, the leading provider of AI/ML software that allows data center operators to operate more efficiently. Prior to joining EkkoSense, Tracy was the CEO of Alabama based Simple Helix, a regional colocation data center operator and MSP. Tracy spent over 21 years with Vertiv, in various leadership positions including leading the global channel organization.

Tracy has an extensive background in sales leadership, and channel development with a strong track record of driving growth while improving profitability. Tracy holds both a Bachelors of Science, Business Administration, and a Masters of Science in Management from the University of Alabama – Huntsville.