Using Сoconut Shells to make durable Concrete

Scientists have found that concrete’s compressive strength can be increased by 4,1% and its flexural strength by 3,4% by adding a small amount of coconut shell (only 5%). In doing so, the material’s performance increased by 6,1% compared to clear concrete.

This effect is due to the fact that the cement paste — the bridge between all solid concrete particles — penetrates into the pores of the shell, firmly binding it with other components.

The data obtained will allow to dispose of large amounts of coconut shell without harm to the environment and improve the quality of building materials. The results of this research were published in Materials journal.

The concept of sustainable development implies that all waste should be completely eliminated, but for now there are no rational methods of recycling plant residues. That’s why scientists are trying to find ways in which they can be used in other economic areas. For example, plant residues may be utilized in the production of new building materials, though material scientists still don’t have enough information on how building materials that contain organic matter are formed, e. g. concrete.

Scientists from the Don State Technical University measured how coconut shell affects the properties of concrete. Coconut shell is a byproduct of coconut processing that is either burnt or thrown away. At the same time, if we learned how to utilize this natural raw material, it can be produced in sizable amounts without fear of depletion.

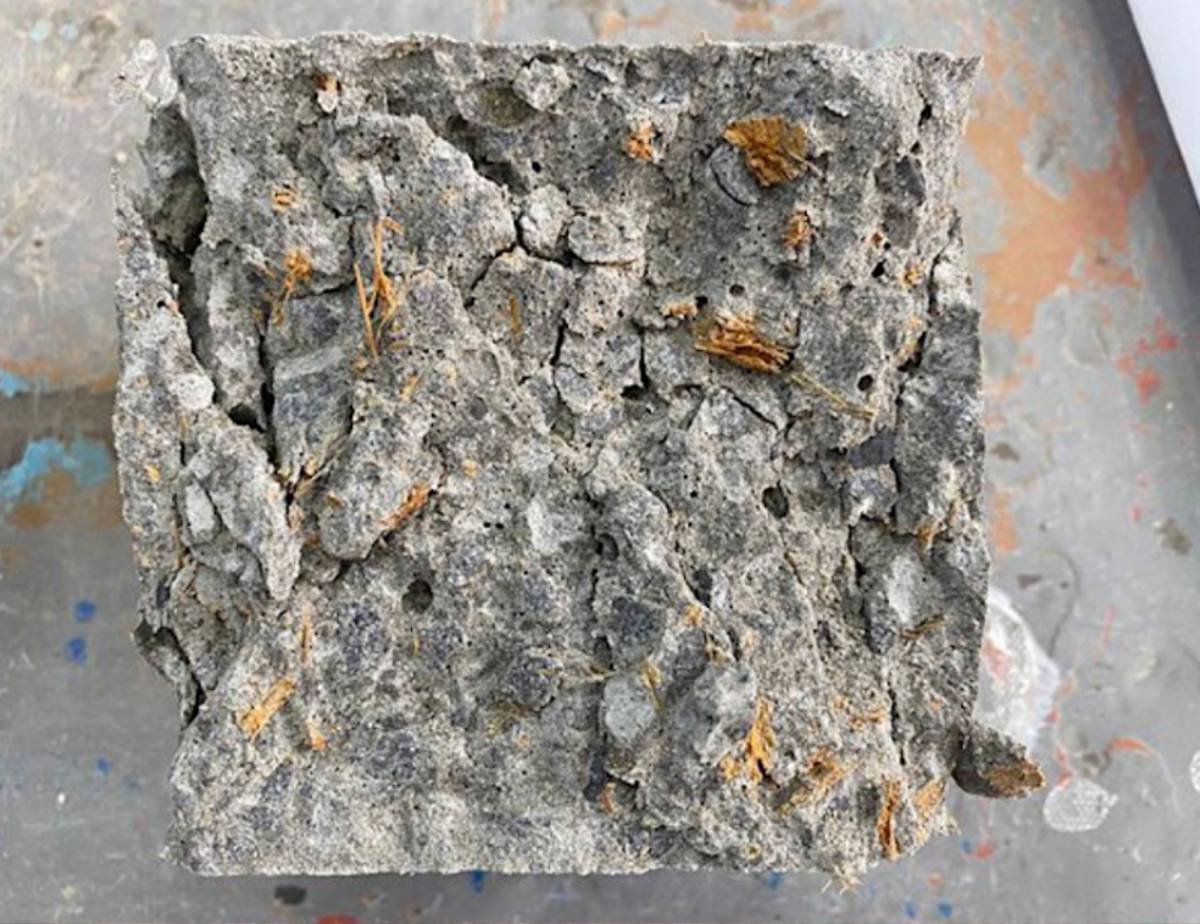

The authors have partially replaced crushed sandstone in the concrete mixture with shell and looked at the density and durability of the resulting composition.

The researchers determined that the highest compressive and bending strength occurred in concrete containing 5% of coconut shell. Moreover, the compressive strength increased by 4,1% and bending strength by 3,4% when compared to clear concrete. Due to the surface roughness and porosity, the shell firmly binded with cement mortar and thereby becoming and additional sealing component.

Furthermore, the shell, less dense than sandstone, reduced the weight of concrete, boosting the coefficient of structural quality by 6,1%. This indicator reflects strength-to-density ratio of the material. But with more amount of shell (up to 30%) the concrete’s strength decreased from 3,4 to 41,4%. This happened because coconut shell is significantly less durable than sandstone.

“In the future we plan to investigate the use of agricultural and also aquaculture byproducts in the technology of eco-friendly concrete. For example, concrete will contain sunflower husk or jellyfish. Our researchers will broaden their understanding of the regularities of the composition, structure and properties of new types of concrete“, says Sergey Stelmakh, candidate of technical sciences, associate professor, leading researcher at Don State Technical University.

The material has been prepared with the financial support of Ministry of Education of Russia within the federal project “Popularization of science and technology”.