Revolutionizing Construction with KICT Contactless Coupler for Precast Concrete

The Korea Institute of Civil Engineering and Building Technology (KICT) has developed a new Contactless Coupler that can efficiently improve the constructability of precast concrete.

Recently, Off-site Construction has been actively used worldwide to solve the problems at complex construction sites. The Off-site Construction method minimizes on-site work by prefabricating parts of the structure and then simply assembling and constructing them on-site. In particular, Korean construction sites are promoting Off-site Construction to solve the problem of aging skilled workers and labour shortages.

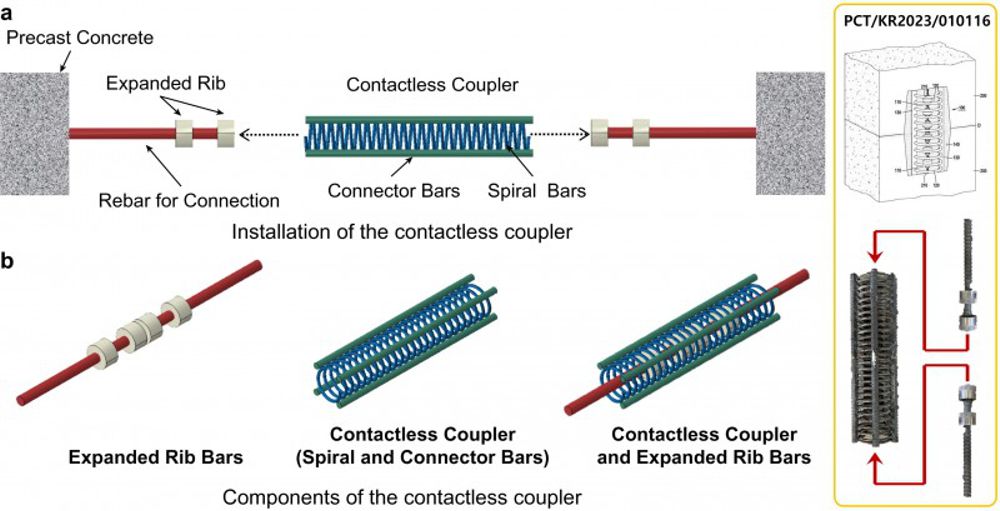

The precast concrete method, one of the representative Off-site Construction methods, is a method of manufacturing and constructing large structural members with divided reinforced concrete. The conventional rigid connection method to connect precast concrete members directly connects two rebars facing each other at the precast concrete connection. This method requires separate rebar processing and fitting a coupler device. If a rigid connection is not secured, it can cause damage to the structure due to poor construction.

The Contactless Coupler, newly developed by the KICT research team, does not require a separately processed rebar and is very easy to install. The Contactless Coupler utilizes the bonding force between the rebar and concrete instead of the direct connection of the rebar.

The tensile stress generated by the rebars installed in the Contactless Coupler is transformed into the bonding force, then transferred to the ‘spiral bar’ and finally to the ‘connector bar.’ Here, the expanded ribs that make up the Contactless Coupler play an essential role in reducing the development length of the coupler by maximizing the bonding force.

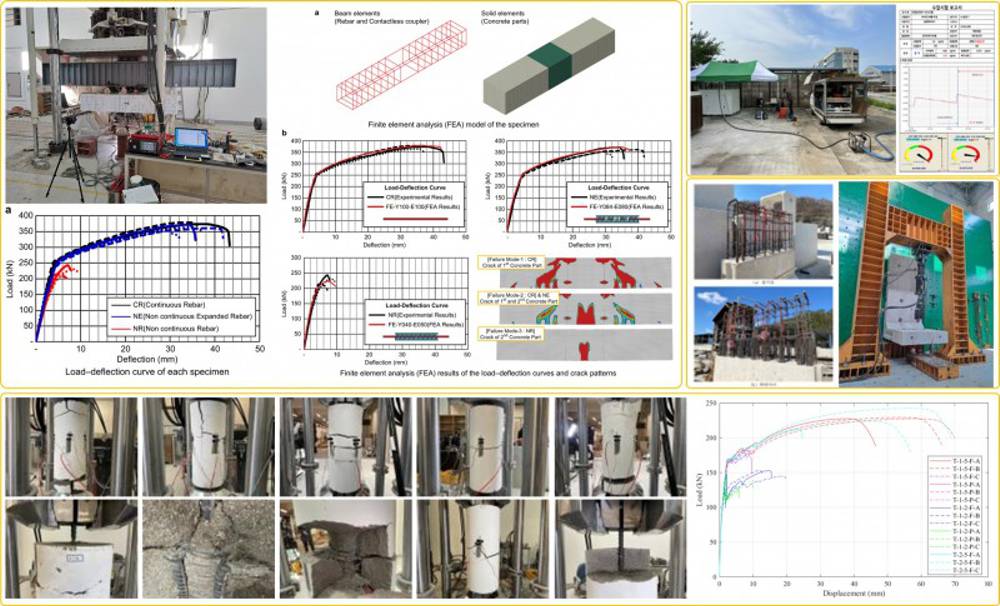

Dr. Kim’s research team conducted beam tests, tensile tests, and real-scale tests to verify the structural performance of the Contactless Coupler. Despite the significant reduction in construction difficulty compared to the existing method, the structural performance required for the coupler was satisfied.

“Contactless Coupler’s excellent performance and ease of use can be used in various Off-site Construction methods,” said Dr. Kim, Kun-Soo, also adding that “In the future, the Contactless Coupler is expected to have a great effect on preventing manpower problems and safety accidents at construction sites based on its easy constructability.”

The core technology of the Contactless Coupler is patented by PCT (International Application No.: PCT/KR2023/010116). The research team is currently researching construction automation, modularization, and lightweight and will develop new design codes and predictive formulas to expand the utility and applicability of the Contactless Coupler.